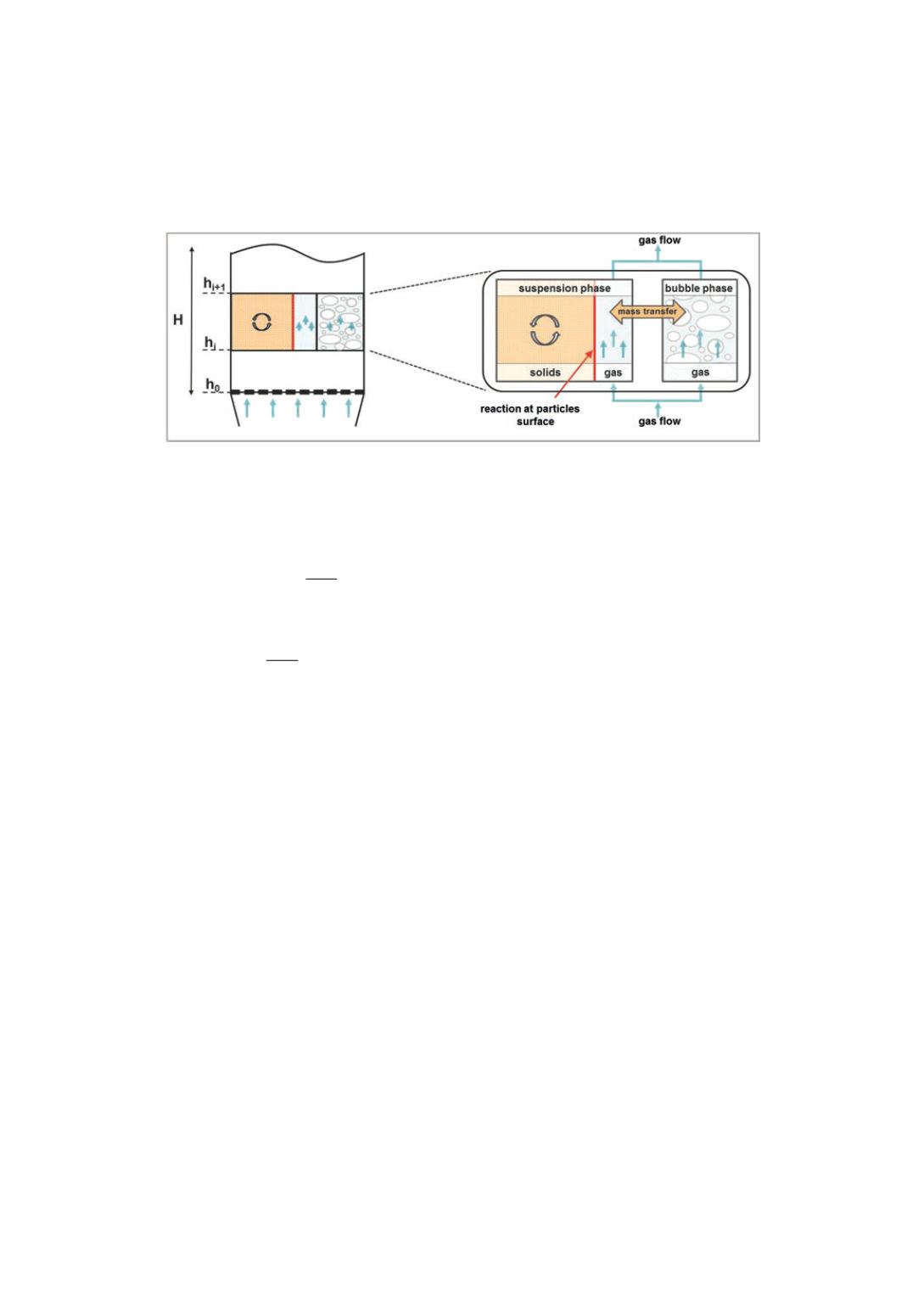

is accessible for the chemical reaction only by mass transport from the “bubble phase”

into the “suspension phase”. The driving force considered for the mass transport is the

concentration gradient of the respective components.

Figure 4

: Schematic of the two phase model approach used

The differential gas mass balances for the two phases are formulated as follows:

Bubble phase:

(

)

[

]

(

)

is

ib b iG

ib

b

mf

c ca k

h

c

uu

,

,

,

,

1

− ⋅

−=

∂

∂

− ⋅

−

ε

(2)

Suspension phase:

(

)

(

)

(

)

educt

ir P mf

b

is

ib b iG

is

b

mf

c k a

c ca k

h

c

u

⋅

⋅

⋅

⋅

−+ − ⋅

−=

∂

∂

−

,

,

,

,

,

1

1

ε

ε

ε

(3)

Where

u

denotes the superficial gas velocity, and

u

mf

and

İ

mf

are the minimum

fluidization velocity and the bed porosity at minimum fluidization respectively. It is

recommended to determine both of these parameters experimentally to characterize the

powder that is used. Alternatively

u

mf

and

İ

mf

can also be calculated from the equations

according to Ergun [10] or Wen and Yu [11] for example.

İ

b

is the local bubble volume

fraction and

c

b,i

the corresponding concentration of each component

i

within the bubble

phase. The mass transport between the two phases caused by the concentration

difference in the “bubble phase” (

c

b,i

) and the “suspension phase” (

c

s,i

) is calculated by

means of a mass transfer coefficient

k

G,i

, based on a correlation by Sit and Grace [17].

The specific mass transfer area

a

b

is determined by the overall, local gas-bubble surface

areas of each volume element. On the assumption that the heterogeneously catalyzed

gas-solid reaction only occurs within the “suspension phase,” the chemical reaction is

considered by means of a reaction constant approach, where

k

r,i

represents the reaction

constant relating to the product component

i

,

a

P

is the total specific particle surface area

that contributes to the reaction and

c

educt

refers to the availability of the gaseous reactant

(chloromethane).

To describe the ideally mixed solid phase an overall mass balance is formulated

according to Equation 4 considering the solids inlet flow rate

ۦ

in

, the particles that are

entrained with the gas flow at the reactor’s outlet

ۦ

entr

, the loss of solids due to chemical

reaction,

ۦ

reac

, as well as the particle flow rate that is separated out by the cyclones and

recycled to the reactor,

ۦ

recycle

.

161