To calculate the entrainment flux

E

0

directly at the bed surface (at

h

=0) there are

different semi-empirical correlations available in the literature such as the approach by

Wen and Chen [15] for example, according to Equation 14.

(

)

5.2

5.0 5.3

5.2

9

0

10 07.3

η

ρ

g

uudA

E

g

mf

v

cs

⋅

⋅

− ⋅

⋅

⋅

=

−

(14)

As can be seen from Equation 14,

E

0

depends on the fluid-dynamic parameters bubble

diameter

d

v

and the superficial gas velocity

u

, which are both provided again by the

fluid-dynamic model, taking the bubble behavior in the dense bed into account.

Furthermore, the entrainment flux at the bed surface also depends on the gaseous

property data such as the density

ȡ

g

and the dynamic viscosity

Ș

g

, as well on the

dimensions of the cross-sectional area

A

cs

of the fluidized bed.

The second term in Equation 13 describes the entrainment mechanism that takes over

above the transport disengagement height (TDH). Therefore an elutriation rate constant

k

,i

approach relating to different particle classes, is used [6]. To calculate

k

,i

, there are

several (semi-)empirical equations available in the literature [14] such as the approach

according to Geldart et al [16], shown in Equation 15. From this equation it can be seen

that particle entrainment above TDH, primarily depends on the superficial velocity

u,

on the density of the gaseous phase

ȡ

g

and on the terminal velocity of a single particle

u

t,i

. Hence, at freeboard heights greater than the TDH, primarily particle sizes with

terminal velocities lower than the superficial gas velocity are entrained.

u

u

u

k

g

it

i

ρ

¸¸

¹

·

¨¨

©

§

−

=

∞

,

,

4.5 exp 7.23

(15)

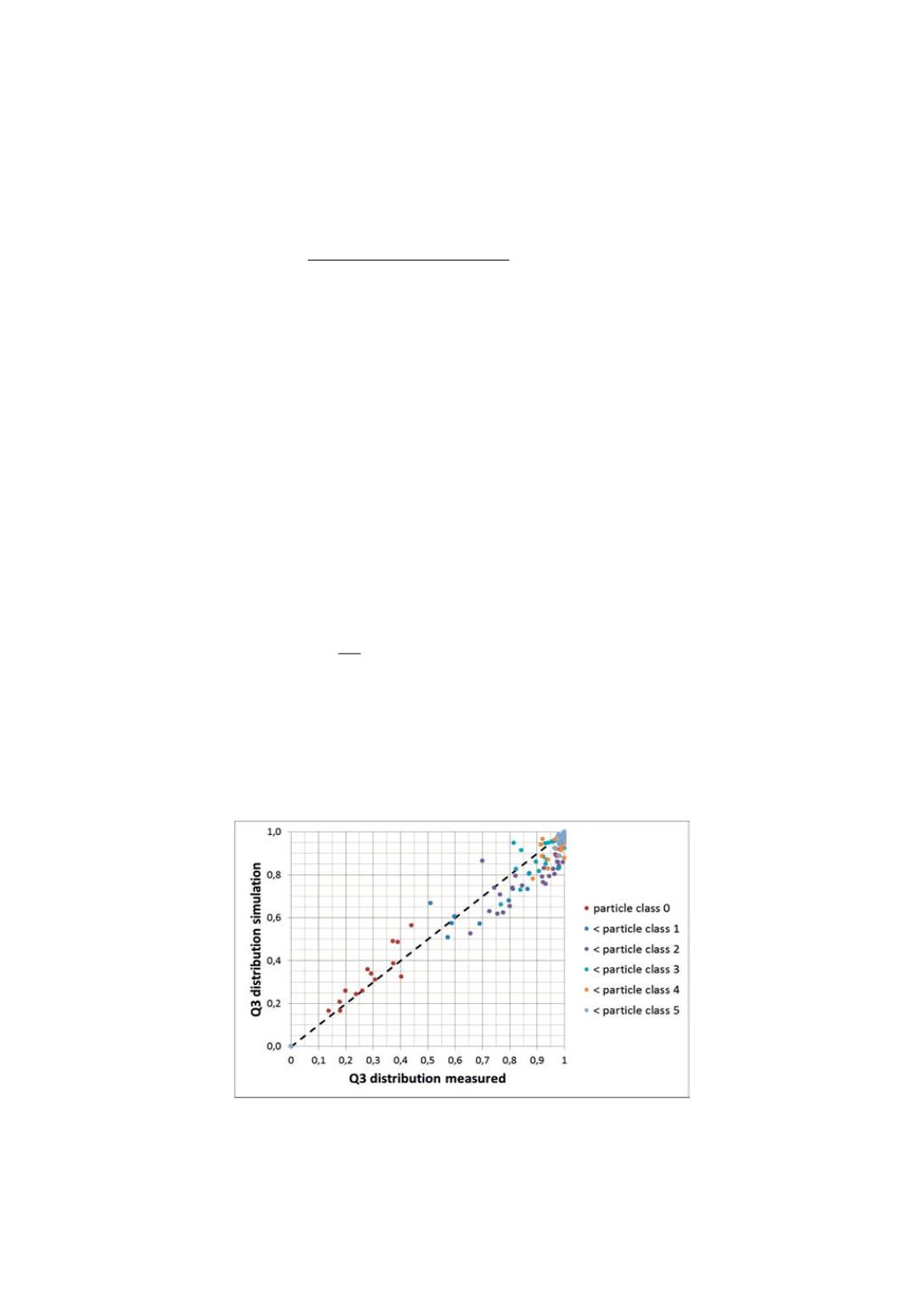

Thus, using Equation 13, the solids mass flow that leaves the reactor with the gas flow

and its particle size distribution can be calculated. Figure 9 shows exemplarily the

results of the model validation for the entrainment of different particle classes by means

of a parity plot that compares the measured and the simulated data. As can be seen, the

simulation results correspond very well to the measured data.

Figure 9

: Model validation results on the entrainment flow rates of different particle classes

167