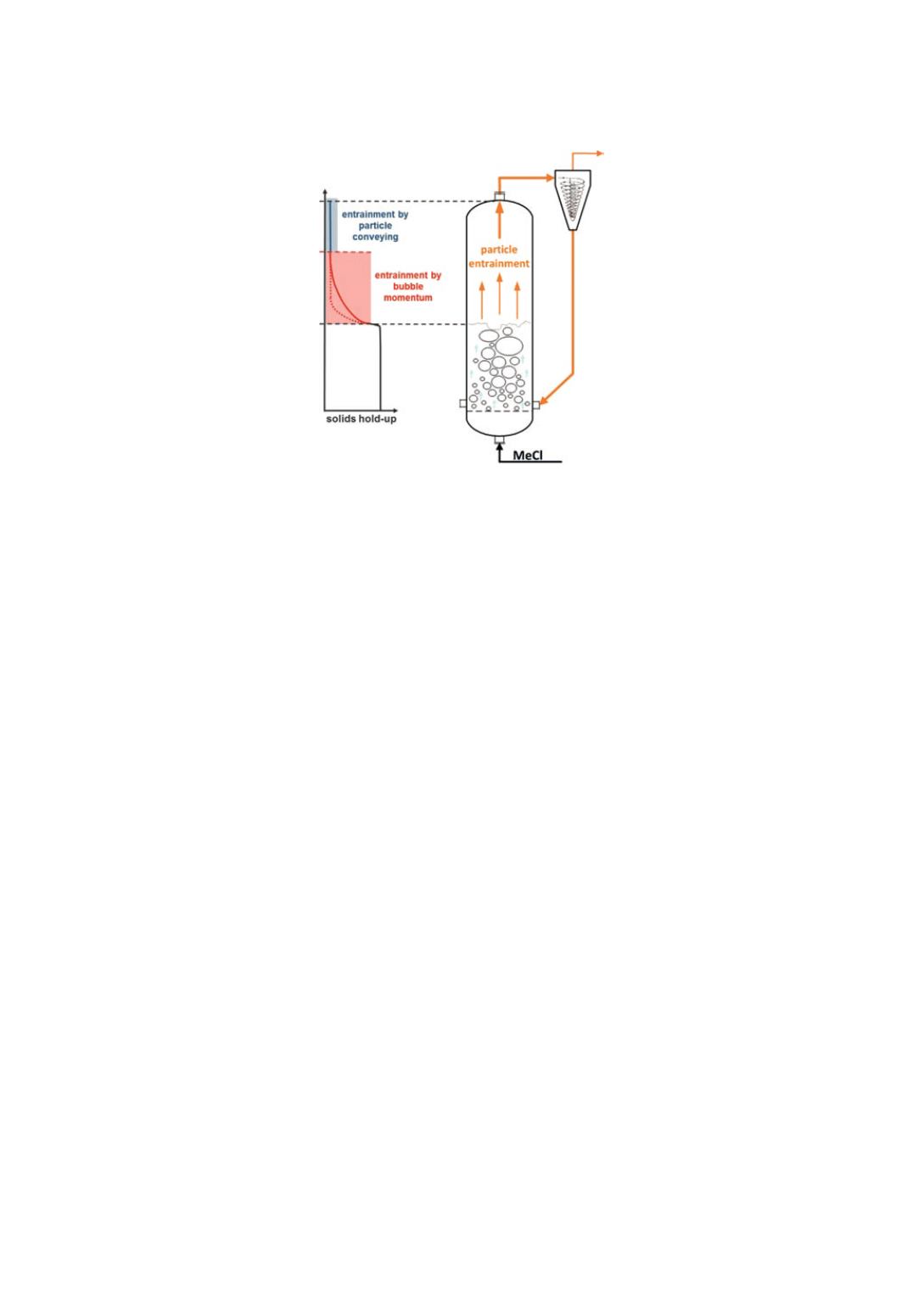

Figure 8

: Particle entrainment in fluidized-bed reactors

As is shown in Figure 8, the solids concentration in the fluidized bed is almost constant

up to the bed surface. At the bed surface, particles, independent of particle size, are

thrown into the freeboard by means of bubble momentum, which mainly depends on

the fluid-dynamic parameters bubble size and velocity. On their way up, bigger

particles fall back to the fluidized bed, so that the solids concentration decreases with

increasing height. At the same time, screening of particles takes place. At a certain

distance, at the transport disengagement height [6], the screening process is almost

finished, so that the solids concentration remains constant until the outlet is reached.

Particle entrainment at this stage mainly takes place by particle conveying only,

depending on the superficial gas velocity.

Thus the particle entrainment model has to consider both mechanisms, the height-

dependent influences caused by bubble momentum and that caused by particle

conveying in order to calculate the particle mass flow rate and the particle size

distribution. The applied model Equation 13 comprises both entrainment mechanisms

to calculate a resulting mass flow rate for each particle class

i

, related to the free cross-

sectional area,

A

cs

[14]. The overall entrained solid mass flow rate then results from the

summation of the individual flow rates, and the particle size distribution is calculated

from the corresponding mass fractions.

(

)

(

) (

)

[

]

i

i

i

cs

i

entr

Q k

ah

Q E A m

,3

,

,3

0

,

exp

Δ⋅

+ − ⋅

Δ⋅

⋅

=

∞

(13)

The first term in the Equation 13 represents the height-dependent entrainment flux of

the particle class

i

. Here,

E

0

is the entrainment flux directly at the fluidized-bed surface,

weighted by the mass fraction of the corresponding particle class. The decrease of the

entrainment flux with increasing distance from the surface

h

is modeled by means of

the dumping coefficient

a,

which is fitted and validated based on experimental pilot

plant data. Though it turned out that the dumping coefficient, and therefore the

entrainment flux, strongly depend on the configuration of internals. The internals act

like precipitators on the particles, reducing the entrainment flux. Here, an exponential

dependency between the dumping coefficient

a

and the reactor’s hydraulic diameter

d

hyd

was found, which allows the influence of the internals on the particle entrainment

by the simulation model to be described.

166