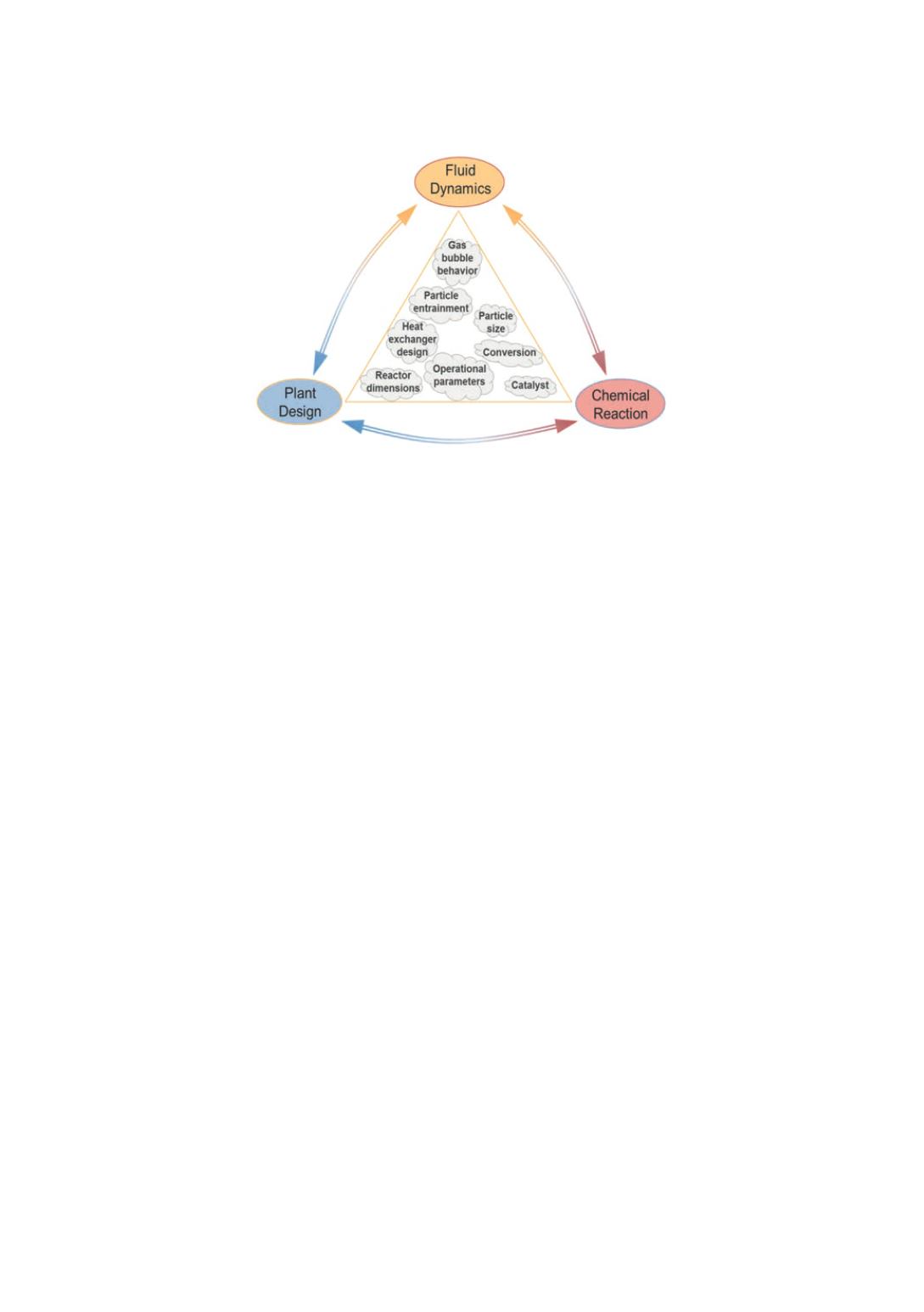

Figure 2

: Influence parameters on the Mueller-Rochow reaction

Basically, various commercial process simulation tools (also for solids applications) are

available. In the field of flow sheet simulation, ASPEN Plus

TM

, for instance, offers

various solids process modeling units that also comprise fluidized-bed reactors.

However, at present, it is not possible, using this tool, to fully describe the complexity

of the interactions between the different impact factors of the Mueller-Rochow

synthesis in detail. On the other hand, there are

c

omputational

f

luid

d

ynamics

simulation tools available, which are capable of describing fluid dynamics in great

detail. Despite great progress in computing capacities during the last years, it is still not

possible to employ this simulation tool for large-scale fluidized-bed reactors due to the

enormous computational effort required to simulate huge numbers of particles.

Hence, in order to meet all the complex and individual requirements, an own rate- based

model approach for the simulation of the Mueller-Rochow process was developed using

the

A

spen

C

ustom

M

odeler

TM

programming environment. Besides the opportunity to

create individual programming code, ACM also offers the advantage of access to

ASPEN property data banks, and, furthermore, the possibility of implementing user-

defined models in the ASPEN Plus

TM

environment, which can be connected to further

downstream processes in order to optimize the entire MCS process chain.

Experimental validation data from pilot plants

When developing a simulation tool it is crucial to have basic experimental data

available to validate the model equations. Therefore pilot plants are needed to provide

scalable and transferable data.

Pilot plant for fluid-dynamic investigations

Especially in the case of fluidized-bed pilot plants, certain requirements concerning e.g.

minimum diameter have to be considered to achieve significant and reliable data. For

investigating the fluid dynamics of the Mueller-Rochow reactor, a fluidized-bed pilot

plant was built in cooperation with Hamburg University of Technology (TUHH), with

a diameter of one meter and a total height of 5.4 meters, including a cyclone and a solids

recirculation system (see Figure 3 on the left). The pilot plant can be equipped with

different interchangeable internals. For the experimental investigations, the gas volume

flow and therefore the superficial gas velocities as well as the dense bed inventory were

159