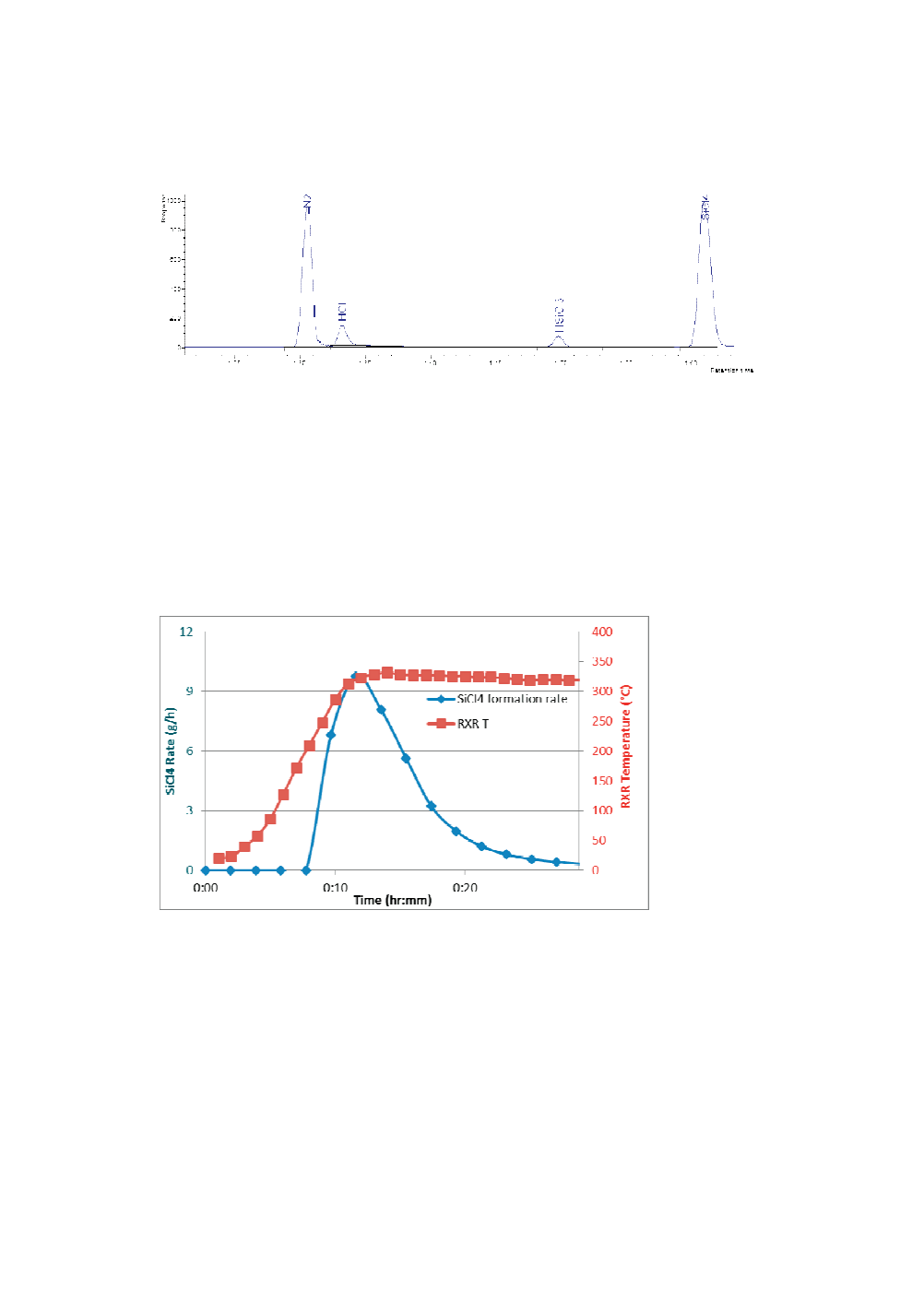

Figure 1.

GC chromatogram of the gas product mixture from the reaction of Si with

CuCl.

The constant flow of N

2

gas served two functions: as a carrier gas to move products

out of the reactor and as an internal standard for quantifying product formation rates.

Figure 2 shows SiCl

4

formation rate (blue line) and reactor temperature (red line) over

the course the reaction. No product was detected below 220 °C. The SiCl

4

formation

rate drastically increased when reactor temperature reached ~280 °C and dropped near

zero about 20 minutes later. Calculation of the area under the blue curve in Figure 2

gave rise to total amount of SiCl

4

formed. Four experiments were performed and the

average yield of SiCl

4

was found to be 107(±4)%.

Figure 2.

SiCl

4

formation rate (blue line with diamonds) and reactor temperature (red

line with squares) curves vs time.

Although the above experiments provide accurate quantification of products, the

reactor temperature-control and the time-resolution of GC were not ideal for

measuring the reaction onset temperature. However, confirmation of SiCl

4

as the main

product allowed us to monitor its formation with a mass spectrometry (MS) method,

and use that as an indicator for reaction rate and progress. The MS method provides

significantly higher sensitivity and shorter cycle time (~0.1 minute). The higher

sensitivity of the MS method also allows use of less reaction mass (~0.5 g) and use of

a chemisorption analyser (CA) to provide better temperature control.

153