CH

3

Cl + 2 S ––> CH

3

(ads) + Cl(ads)

(1)

CH

3

(ads) + S

––>

CH

2

(ads) + H(ads)

(2)

CH

3

(ads) + H(ads)

––>

CH

4

(g) + 2 S

(3)

CH

2

(ads) + S

––>

CH(ads) + H(ads)

(4)

CH(ads) + S

––>

C(ads) + H(ads)

(5)

CH

2

(ads) + CH(ads) + C(ads)

––>

Coke + nH(ads)

(6)

Hydrogen, methane and other hydrocarbons with two to six carbon atoms are

commonly observed in the direct process.

11

Muller suggested that methane and

hydrogen were generated from reaction of two methyl radicals through reaction 7.

12

Alternately, methane can be generated from reaction of an adsorbed methyl group

with an adsorbed hydrogen through reaction 3. Chain growing for formation of other

hydrocarbons can occur in a reaction similar to 6.

2 CH

3

· ––> CH

4

+ H

2

+ C

(7)

Methyl chlorosilanes such as CH

3

SiHCl

2

(MeH) and (CH

3

)

2

SiHCl (Me2H) are formed

in the direct process. They are valuable for manufacturing of coupling agents and

other functional products.

1

The combined selectivity of these Si-H containing by-

products was found highly variable. Numbers in the range of around 1% to greater

than 50% have been reported.

1,13

It is reasonable to assume that the hydrogen ligands

originate from methyl chloride. However, there is no clear evidence of the direct

sources. Some possible sources include methyl groups, partially decomposed

fragments such as -CH

2

-, H

2

generated form reaction 7, or adsorbed hydrogen

generated from reactions 2 and 4.

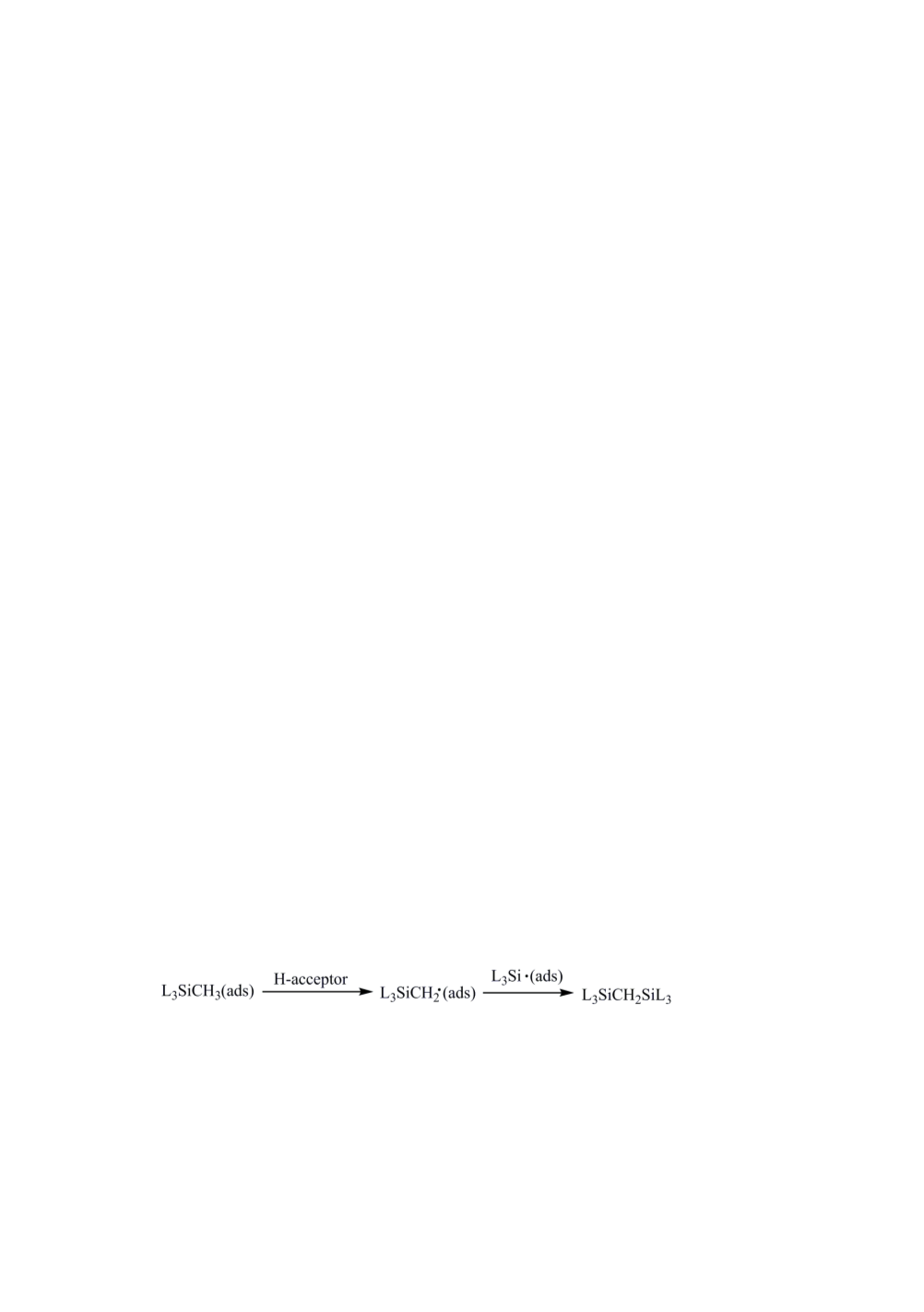

In the direct process, there are by-products with the common L

3

Si-CH

2

-SiL

3

formula

(where L are ligands such as CH

3

-, Cl-, or H-). These by-products are collectively

named silmethylenes. They are part of the high-boiling by-products generally known

as direct process residue.

14

Silmethylenes were generated with higher yields in the

reaction of methylene chloride (CH

2

Cl

2

) and HCl mixture with silicon.

15

In that

reaction, the -CH

2

- group should be readily formed after cleavage of the two C-Cl

bonds in CH

2

Cl

2

. In the direct process with CH

3

Cl, the -CH

2

- must be generated from

a methyl group after cleavage of one C-H bond. However, the formation mechanism

of silmethylenes is not well understood. We speculate that the reaction mechanism

involves reaction of a surface methylene group with two silyl groups (8). The other

possible mechanism involves decomposition of the methyl group that is already on an

adsorbed MCS molecule to generate a Si-CH

2

- moiety, which combine with another

silyl group (9).

2 L

3

Si·(ads) + ·CH

2

·(ads) –––> L

3

Si-CH

2

-SiL

3

(8)

(9)

The side-reactions involving unproductive methyl groups can be summarized by

Scheme 1, at least from the mass balance standpoint. Scheme 1 shows that: (a) some

unproductive methyl groups are incorporated into methane and higher hydrocarbons

without going through C-H bond cleavage; (b) the remaining unproductive methyl

groups cleave different numbers of C-H bonds to generate hydrogen ligands and CH

x

(x = 0, 1, 2) fragments; (c) the hydrogen ligands are eventually incorporated into MCS

with Si-H bonds, hydrogen gas, or methane; (d) the CH

x

fragments are eventually

149