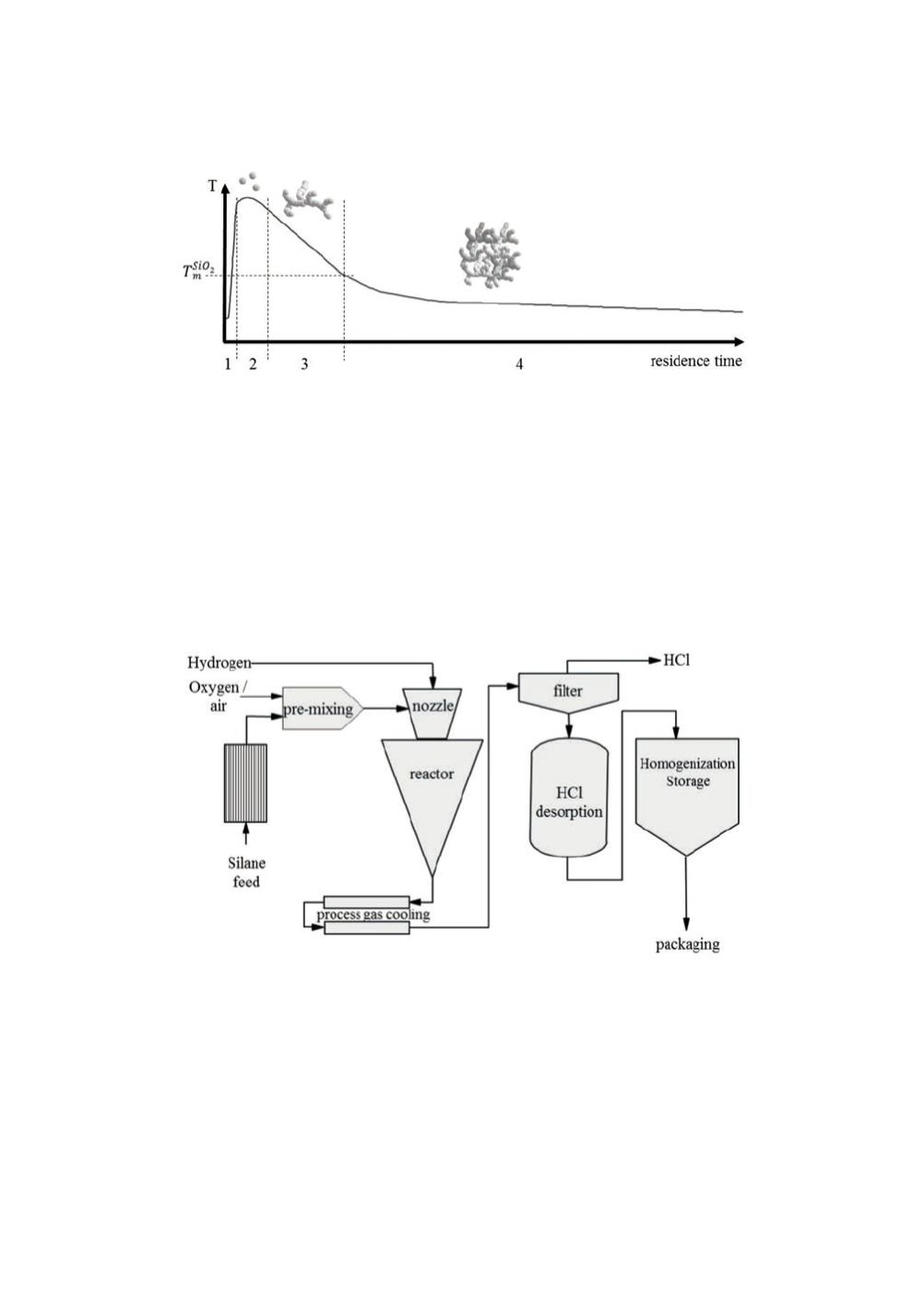

Figure 1:

Particle growths scheme of pyrogenic silica.

Several grades of pyrogenic silica are commercially available, which mainly differ in

their specific surface area. Typically, silica grades in a range of 50 – 400 m

2

/g are

available. The specific surface area is determined by the size of the primary particles.

By increasing the size of primary particles, the specific surface area drops. The primary

particles size can be precisely controlled by the flame temperature and/or residence time

of the primary particles in range 2 of the particle growth scheme.

Fig. 2 shows a schematic illustration of the net process of pyrogenic silica production.

Figure 2:

Illustration of the net process of pyrogenic silica production.

After pre-mixing of air and silane feed, all components are introduced by means of a

nozzle into a reactor, where combustion and subsequent particle formation occurs. The

particle fraction is separated after cooling from the main gas volume. A very important

step is the desorption of HCl traces from the silica surface. The pyrogenic silica is

collected in silos for final homogenization to guarantee constant product properties and

finally packed into bags.

109