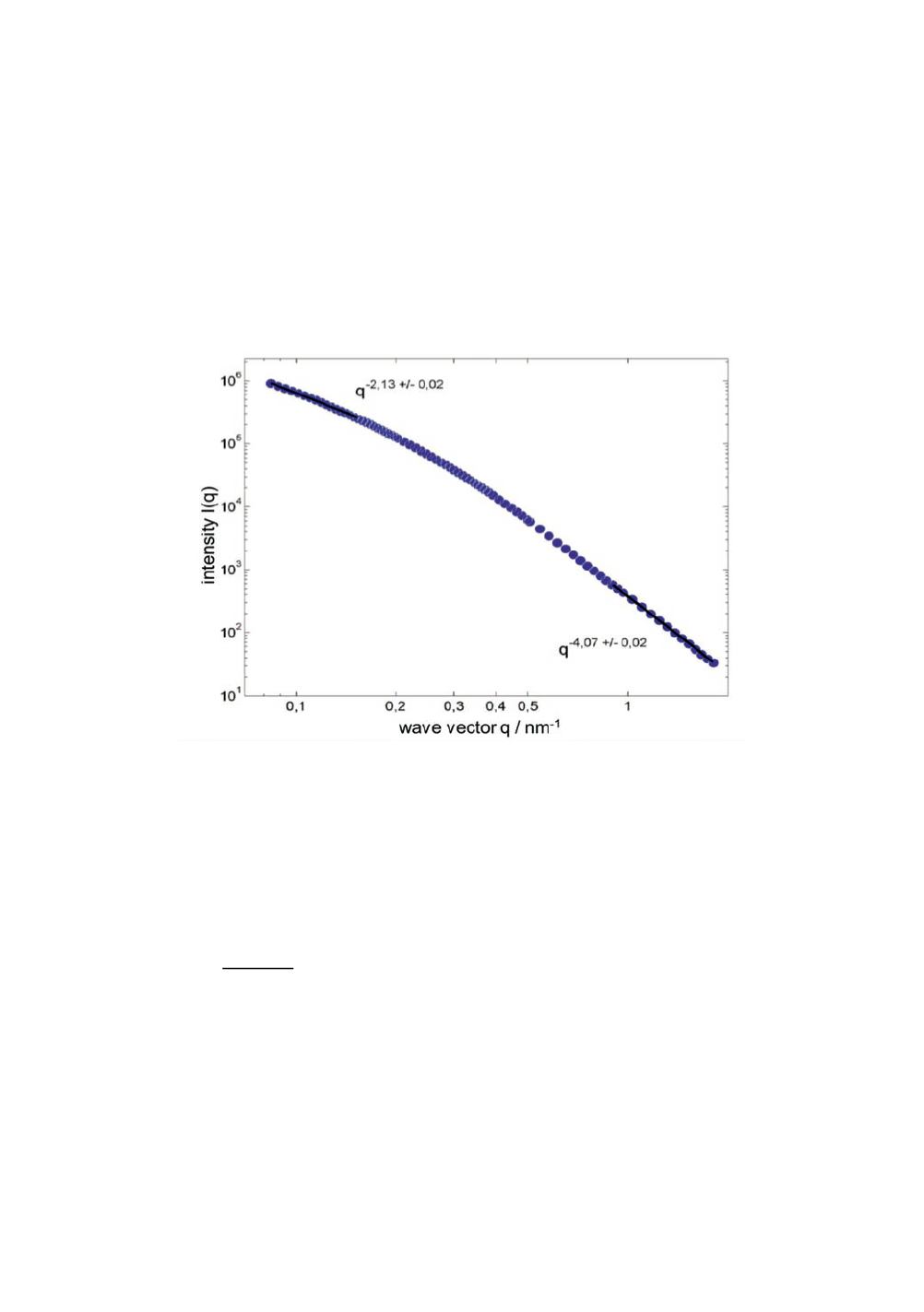

surface without surface porosity. The mass fractal dimension of 2.13 indicates an open,

very space filling structure. However, in literature even lower fractal dimensions in the

range of 1.5 – 1.9 have been reported for pyrogenic silica [28, 29]. The differences

might be due to different conditions within production processes of the pyrogenic silica

producers. The space-filling properties of pyrogenic silica aggregates are an important

feature which directly leads to the use to pyrogenic silica as rheological control

additive, thermal insulation material, and reinforcing filler [30]. The different

application will be discussed later.

Figure 10:

Scattering date for pyrogenic silica of 200 m

2

/g specific surface area.

Particle size and particle size distribution are important parameters to characterize

powders [31]. However, particle size of hierarchical systems like pyrogenic silica is an

ill-defined feature. The values strongly depend on the measuring technique and

conditions of sample preparation. Depending on the size range of the hierarchical

system, different techniques are employed. Particle size of primary particles within the

sintered aggregates can be determined by TEM analysis or from the specific surface

area according to eq. 7 which results in the Sauter diameter D

pp

of primary particles.

ܦ

ൌ

ௌௌή ఘ

ೄೀ మ

(7)

The Sauter diameter of primary particles of silica with 200 m

2

/g specific surface area is

ca. 14 nm. The Sauter diameter of pyrogenic silica is often cited in scientific literature

but this is somehow misleading since it implies that isolated primary particles are

accessible.

For most applications, the aggregate size is the relevant parameter. An established

method to determine the particle size of sub-micron particles is photon correlation

115