Target product of the Müller-Rochow methylchlorosilane process is

dimethyldichlorosilane, Me

2

SiCl

2

. However, an important side product is

methyltrichlorosilane, MeSiCl

3

, of 3 – 15% relative yield, which is also often used as a

raw material in pyrogenic silica production [2].

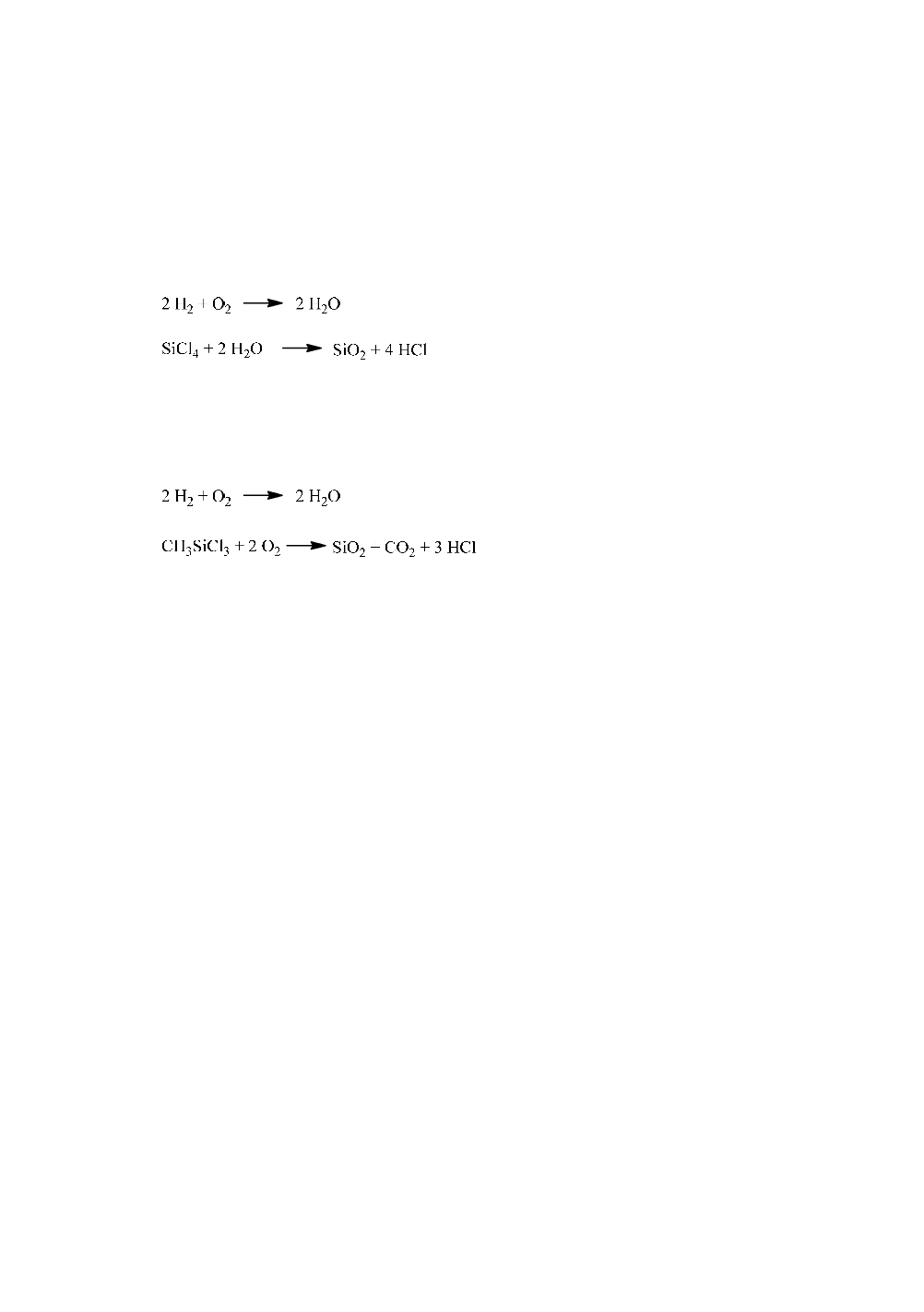

The formation of pyrogenic silica from SiCl

4

is a high temperature hydrolysis in a

hydrogen-oxygen flame according to Eqs. 1 and 2.

(1)

(2)

From thermodynamic data of Eq. 1 and 2, an adiabatic flame temperature of ca. 1700

K can be calculated.

The corresponding reaction of (CH

3

)SiCl

3

is a high temperature hydrolysis/oxidation

(Eqs. 3 and 4).

(3)

(4)

The oxidation of the methyl group results in a higher adiabatic flame temperature of

approximately1900 K. Based on the stoichiometry of eq. 4, no additional water is

needed for the hydrolysis of the Si-Cl bonds. However, the hydrogen-oxygen flame

reaction (eq. 3) is still needed to provide enough energy for the particle formation as

discussed below.

The particle formation is assumed to be a complex process of chemical reactions

combined with different particle growth processes. Fig. 1 schematically depicts this

process. Main parameters to control the particle growth are the absolute temperature

and the residence time of particles in a certain temperature range [3].

The notion is that in the very early stage of the process cascade SiO

2

molecules form,

which instantaneously fuse to so-called proto-particles of ca. 1nm in size (range 1 in

Fig. 1) [4]. This happens close to the hottest part of the flame. Due to the high

temperature, which is far above the melting temperature of amorphous SiO

2

(

ܶ

ௌைଶ

),

proto-particles are in fact droplets of liquid SiO

2

. Collision of proto-particles results in

particle growth by coalescence (s. range 2). Finally, primary particles of 5 – 50 nm in

diameter result. Their size primarily depends on temperature and residence time. The

viscosity of molten SiO

2

strongly depends on temperature and water content [5]. Hence,

with decreasing temperature the viscosity heavily increases and below a certain

temperature complete coalescence of particles upon collision is no longer possible. As

a consequence, particle-particle collision in this cooler part of the flame (range 3)

causes aggregation [6]. The primary particles within the aggregates are fused by sinter

bridges. When the temperature drops below the melting temperature of SiO

2,

agglomeration starts. Within the agglomerates the aggregates hold together due to

strong surface forces like London, Keesom, and van der Waals forces [3].

108