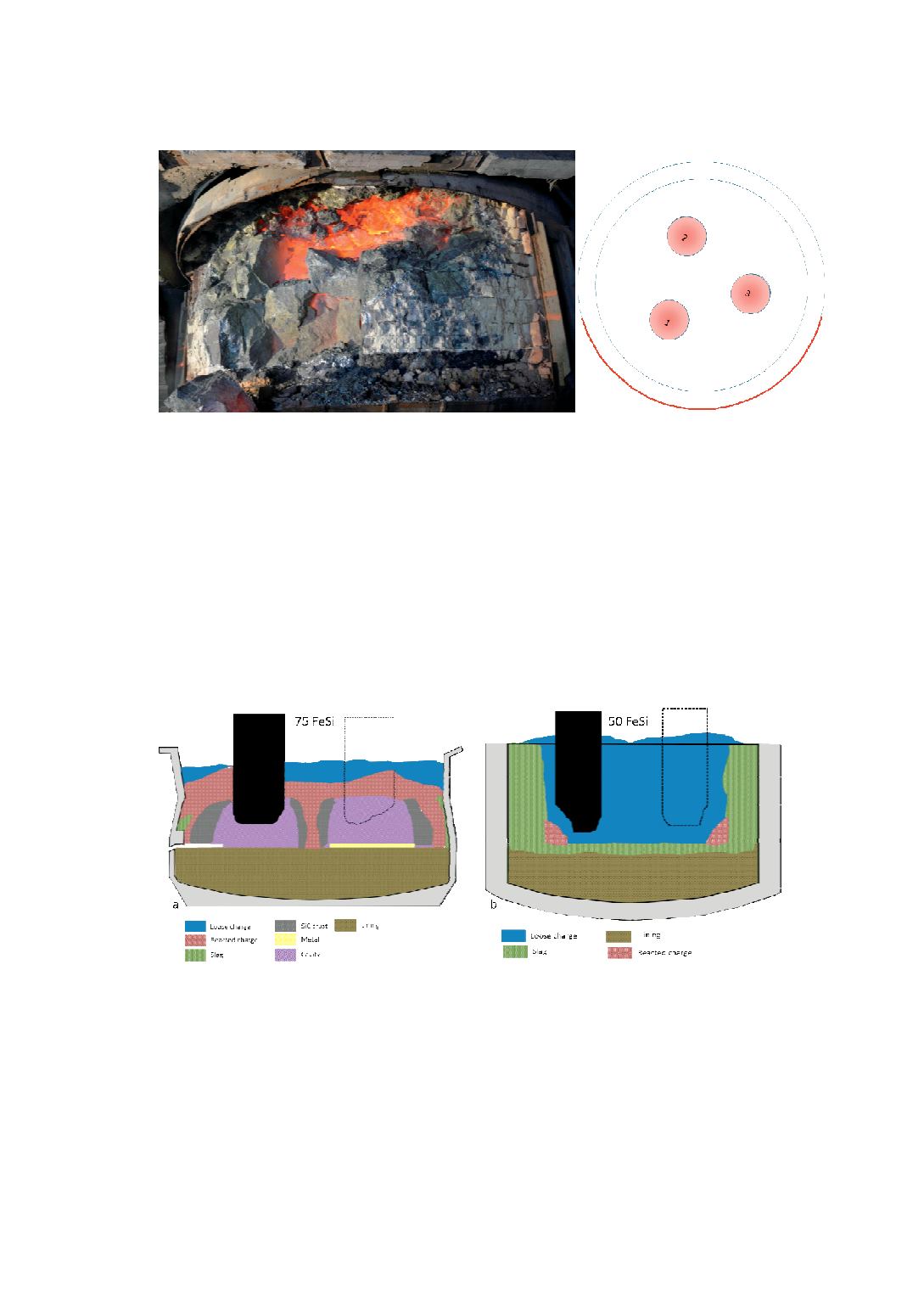

Figure 6:

Pictures of furnace no.1 in Wacker with marked excavation front.

Excavations observation and discussion

From visual observation and classification of collected samples, it was possible to distinguish a few

main zones in industrial furnaces. As previously reported, only considering the horizontal crossed

section, zones in Si furnace can be divided to [3]:

1)

Inactive zone, located around walls of the furnace, mostly consist of deposited slag and pre-

melted raw materials. This zone was observed in all excavation.

2)

Electrode track zone, as the furnace shell is rotating

3)

Inner zone, area located in central part of the furnace towards the electrodes.

However, this description does not give completed overview about reaction zones in the furnace.

Figures 6 and figure 7 present overview of reaction zones of 5 furnaces. Sketches presents whole

internal part of the furnaces parts including the zones close to electrode where Si production occurs but

also upper part of the furnace where condensation reactions take place.

Figure 7:

Overview of zones in two FeSi furnaces: a) 75 FeSi in Finfjord, b) 50 FeSi in Elkem

Bjølvefosen.

As figure 7 shows that the zones found in two FeSi furnaces, differ significantly. For high Si

operation (75FeSi), loose materials were found on the top of the charge. Below this layer,

reacted charge was observed. The term "reacted charge" can be defined as raw materials

including smelted quartz with possible condensate deposition and SiC from carbon materials.

Picture of sample showing reacted charge is presented in figure 8a . Moreover, visible cavities

were found around the electrodes tip surrounded by the SiC crust with gas channels. Picture

of SiC crust is presented on figure 8b. Under the electrodes, a mixture of melted quartz, SiC

and alloy was seen. The production of silicon in this zone is assumed to be the main reaction

37