due reaction between SiO and SiC. Small amount of slag was noticed on the outer part of the

furnace, in the co-called inactive zone.

In 50 FeSi furnace one zone of loose charge material from the charge top and down to the

electrode tip position was seen. On the outside of the electrodes, from bottom to the top of the

charge was massive slag layer. In addition, a more than 1m high slag layer was present

covering the entire bottom. In some areas, slag layer was deposited 0.5 higher than electrode

tip. This slag layer contained Ca-Al-silicates but was also spiced with small SiC particles. All

slag samples investigated contained quite some carbon from the SiC. Presence of condensates

layer in the upper part of the furnace or SiC crust around electrode tip was not observed.

Furnace charge was very easy to remove, it was running out of the furnace and the material

looked more like a coal bed, than a cavity operation.

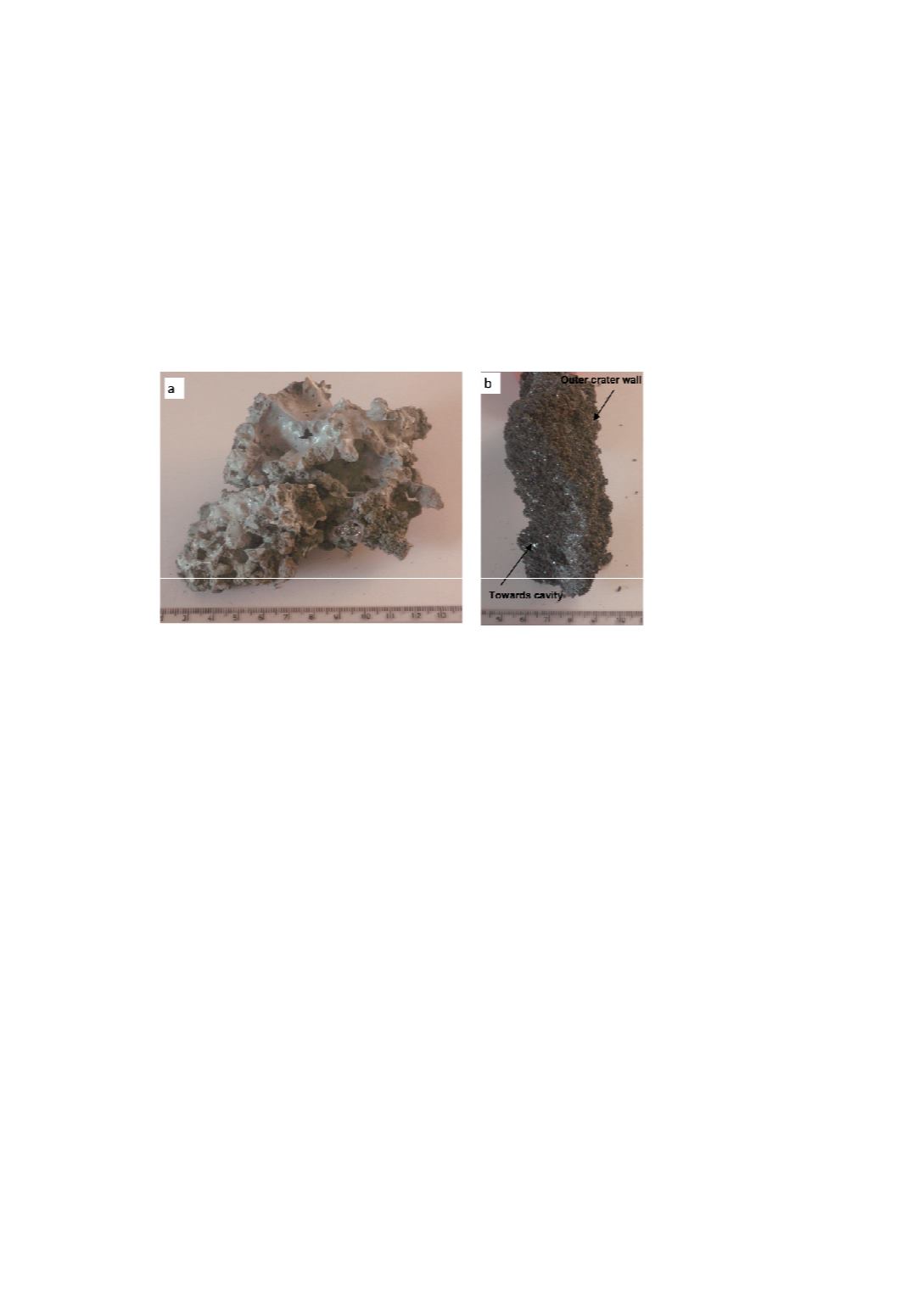

Figure 8:

Materials found in 75FeSi: a) reacted charge, b) SiC crust.[2]

38