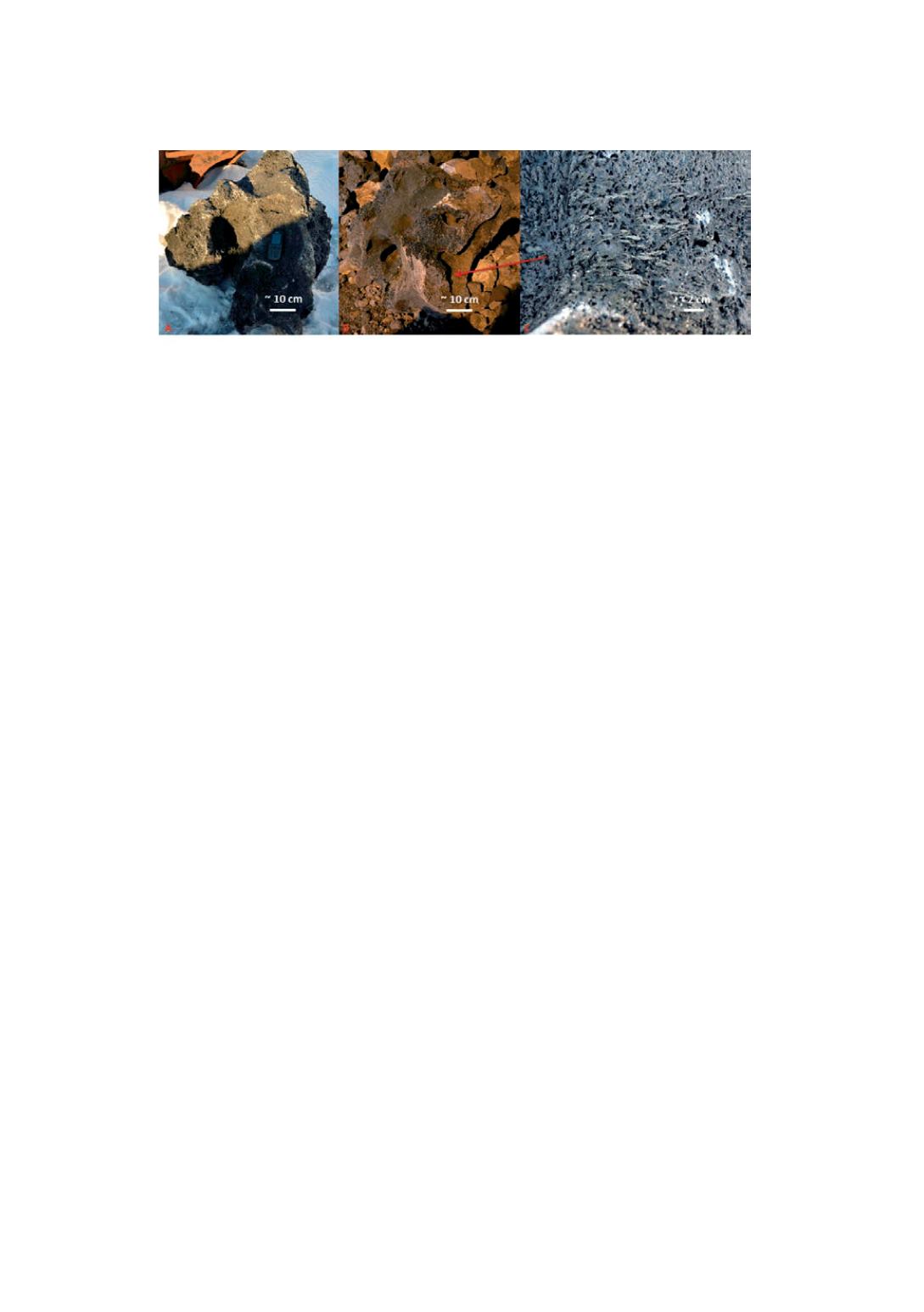

Figure 13:

SiC deposit with gas channels (A, B), SiC crystals on the channel wall (C). [3]

During the excavation of furnace no. 1 at Wacker it was possible to have close look

and pick up the sample directly from area around the electrode tip. Electrodes were

still in their working positions; they were not cut off before start of excavation, as it

was in case of other Si furnaces. Around the electrode tip there was area filled with

the mixture of SiC, Si and melted quartz. It is believed that the production of silicon

in this zone is to be preliminary, thus it was marked on the figure 9a as Si production

zone. Additionally on the figure 9a, below electrode the cavity was marked. It is

believed that it was filled with melted materials from Si production zone, as furnace

was stopped. It is expected that in this area the electric arc will go towards Si bath or

the SiC crust. Similar cavity was observed during the excavation in Elkem

Thamshavn, however there was only SiC crust surrounding the electrode tip. Below

the electrode small region with metal bath was identified, however the major zone in

the bottom was mixture of green slag and SiC.

Some very small areas of metal bath was observed in Wacker furnace no. 1 below

electrodes. However, the main phase was mixture of SiC and Si, which was about 2m

thick. In case of furnace no. 4 the liquid metal leaked out during the dig out, thus was

very difficult to estimate area where it was cumulated.

Conclusion

•

Five industrial scale furnaces (two FeSi and three Si) were excavated for the

purpose of finding reaction zones.

•

Excavation of two FeSi furnaces indicate that during 50FeSi production process

heat to the system is delivered via coke bed. While 75FeSi production process

seems to be cavity operation as Si production process.

•

Inactive zone, consisting mostly of thick slag layer seems to be significant zone

in the furnace. Thus, it limits the space for "active" zones, for example hinder

the flow of the charge material but also can cause the problems with the

tapping a furnace.

•

Distribution of the zones, and appearance of different zones it self can firstly be

determined by furnace operation strategy, not by used raw materials. Wacker

furnaces used similar raw materials-however, zones and they distributions in

those furnaces differ significantly.

Acknowledgement

The authors wish to thank the staff in Finfjord, Elkem Bjølvefosen, Elkem

Thamshavn and Wacker Holla for great support and hospitality during the excavation.

41