Upgrading of condensate

Applying the fast pyrolysis process, the bio-oil liquid product, depending on the quality,

can be sold and applied as a burner fuel directly. The process is well demonstrated and

several stakeholders exist globally [13]. Standards for bio-oil burner fuel exist as well,

even though bio-oil is currently not a well-established market product. Standardization

for other purposes is ongoing [14]. Catalytic bio-oil upgrading processes have not yet

been sufficiently demonstrated, and their technology readiness level (TRL) is low. The

catalysts used are mainly commercial refinery catalysts; new catalyst development is

ongoing at research stage. The commercial catalysts as well as the process itself are

facing several critical bottlenecks that are hindering successful demonstration and

commercialization. The short catalyst lifetime and the occurring deactivating/poisoning

mechanisms are the main challenges. The catalyst deactivation is caused by the coke

formation on the catalyst surface, temporarily blocking the active sites, while mineral

deposition can irreversibly deactivate the active sites (poisoning). Although the

catalytic pyrolysis oil upgrading processes are not commercial and critical challenges

remain, there are considerable efforts made towards demonstration. The efforts made

in the catalytic upgrading processes are expected to increase, hence the TRL, mainly

due to several reasons: (i) current techno-economic calculations show great viability

potential of liquefaction processes (pyrolysis and hydrothermal liquefaction) in

production of biofuels and (ii) finding new ways to utilize existing oil refineries,

infrastructure and know-how will be essential.

System perspective

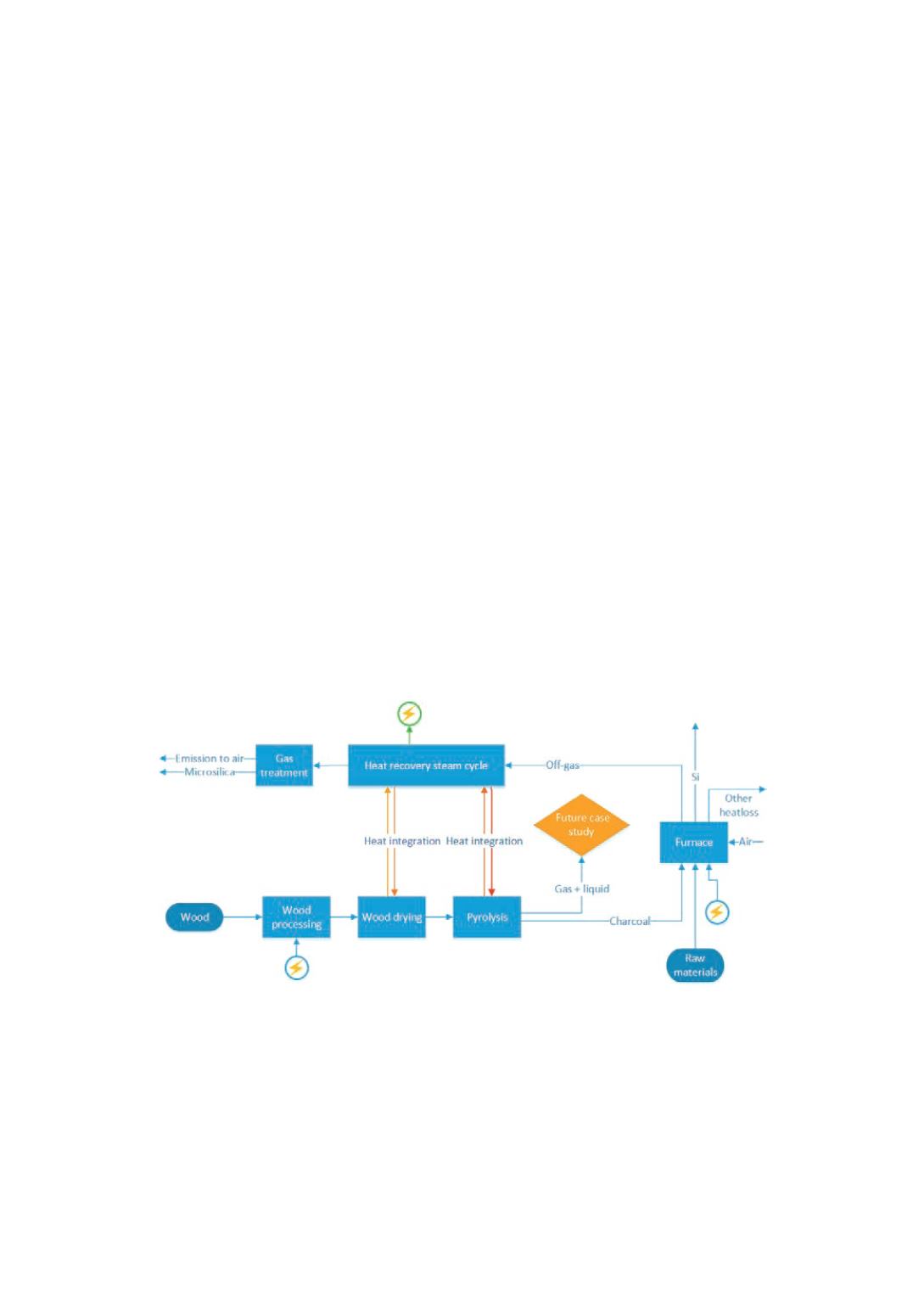

There are several possible configurations for an integrated charcoal-silicon process and

the one showed in Figure 2 is just given as an example, different configurations will be

investigated in future case studies. However, already at this stage some aspects and

consequences of an integrated process can be discussed.

Figure 2.

Simplified block flow diagram of a potential CNMP concept.

From a given biomass specification and operation parameters such as temperature and

residence time, the pyrolysis unit/carbonizer will require different heat demand, which

will influence output flow rates, composition/element balance, and energy content of

charcoal, gases, and condensate. In addition, the integrated process is strongly governed

by specified furnace operation. Upstream; the furnace load and composition of raw

materials determine the necessary charcoal feed, which again affects pyrolysis load and

required wood input, as well as several related processing stages; wood input, de-

6