to be energy efficient. Here, integration refers to both energy integration and mass

integration. Energy integration can be to use heat from the silicon process and auxiliary

equipment as a source of energy for charcoal production (and vice versa). Mass

integration denotes recovering gas, fines, and condensate from the pyrolysis process

and integrating them into either energy production units such as boilers or gas turbines,

upgrading units or recovery units.

Taking this into consideration, the main objective with this paper is to perform a

detailed characterization of the main products from pyrolysis at conditions relevant for

a future Elkem process. The goal is that these and similar results can be used to conduct

a system study of the complete process; where charcoal production is integrated into

the silicon production process.

Method

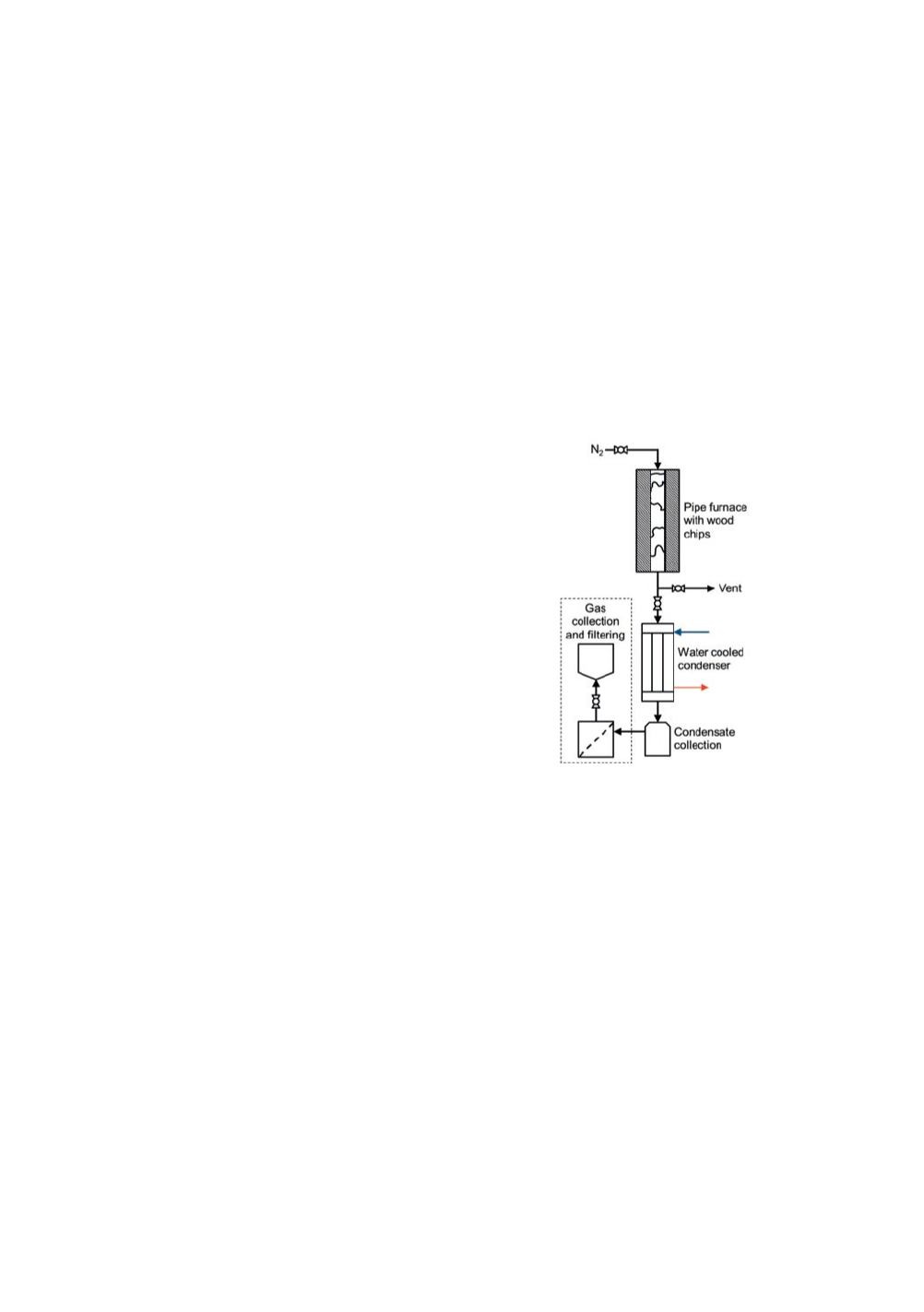

Small scale pyrolysis experiments were performed in

order to obtain a complete mass and chemical energy

balance including the elemental balance for a feedstock

relevant to the CNMP concept. Pine wood chips were

selected as a reference feedstock since it is currently

used in the existing silicon production process.

Although the main product of interest is the charcoal,

there may be economical incentives to optimize the

recovery of condensates. Hence the experimental setup

was designed to maximize the recovery (but not the

production) of condensate. The experimental setup is

schematically described in Figure 1, and consists of the

following parts. A 40 mm pipe furnace approximately

500 mm long, a propylene-glycol cooled condenser

operating at a set temperature of 0

Σ

C, a glass wool filter

designed to trap aerosols and a Tedlar bag for gas

collection. The experiment was started by filling the

inner pipe of the pipe furnace with wood chips and the

pipe was then weighed and installed in the furnace. The

biomass was then dried at 120

Σ

C using a nitrogen purge

of 5 l/min for about 60 minutes. During the drying process the condenser was by-passed

and the steam was vented directly to the fume hood. After the drying process, the

nitrogen and vent valves were closed and the valves to the condenser and gas bag were

opened. Thereafter, the sample was heated with a heating rate of roughly 13 °C/min to

400-600

Σ

C depending on which final temperature was investigated. After the

maximum temperature was obtained the samples was kept there for 30-180 minutes

depending on the chosen soak time. Consequently, during the pyrolysis experiment no

purge gas was used and the pressure in the system was in practice "regulated" with the

expansion of the Tedlar bag (i.e. atmospheric conditions). After the required soak time

had been obtained the valve to the condenser and gas bag was closed, the furnace

switched off and the samples were allowed to cool overnight with a small N

2

purge to

prevent the charcoal samples from catching fire. Once the furnace had cooled off, the

gas and condensate collection systems and the amount of charcoal were weighed and

the yield was determined. The feedstock and products, condensate and charcoal, were

analysed to determine the elemental composition and the heating value. The collected

gas was analysed using a Varian CP-4900 micro-GC. Finally, a complete mass and

Figure 1.

Schematics of the

experimental setup

3