chemical energy balance was determined including the distribution of the major

elements (C, H, O). In total, 19 different experiments were performed. The

interpretation and evaluation of all the experimental results are reserved for an

upcoming publication by the authors and this work focuses on the mass and chemical

energy balance from one of these experiments. The conditions for the chosen

experiment were as follows: heating rate of 13 °C/min, 500 °C final temperature, and a

soak time of 3 hours.

Results and discussion

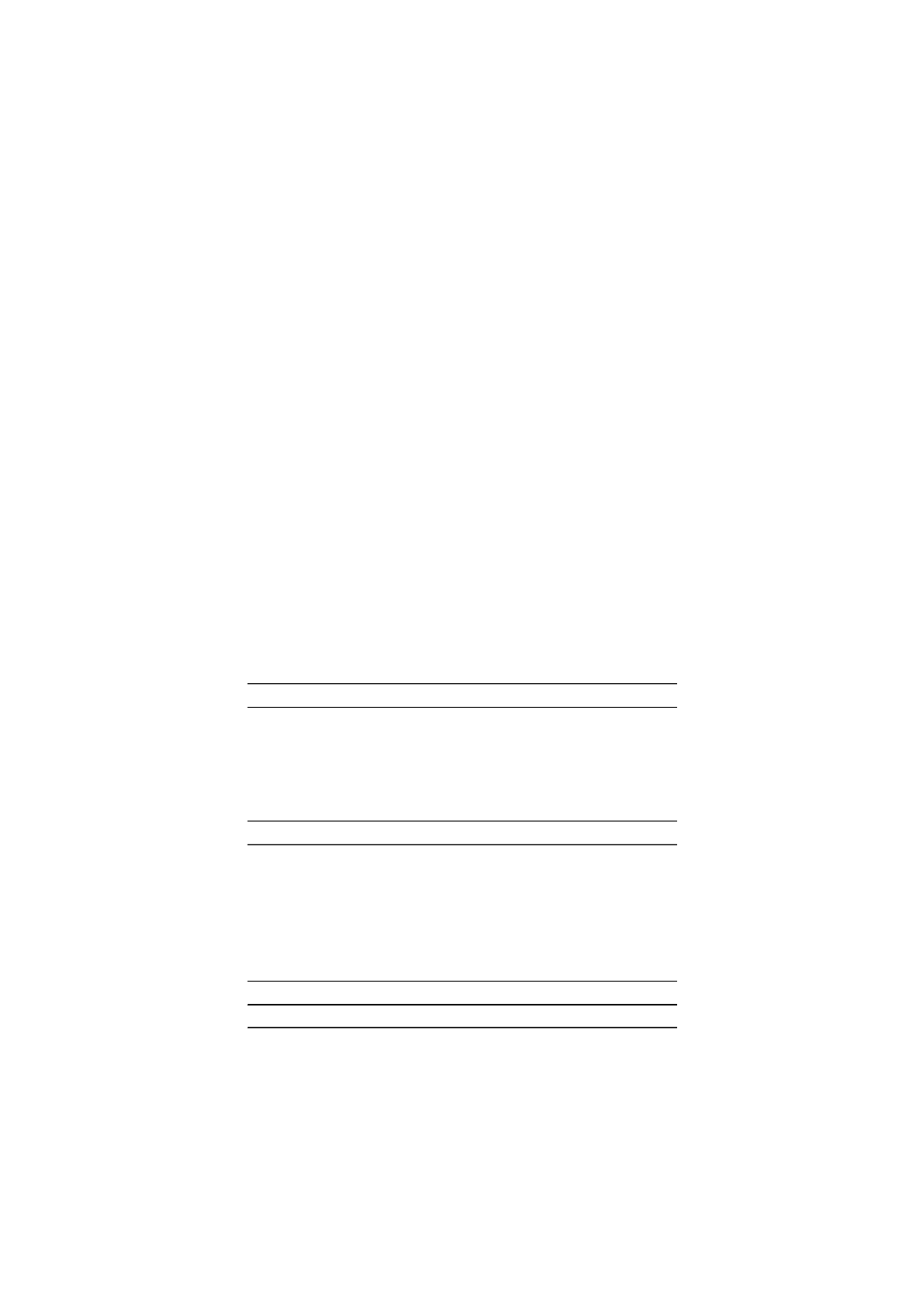

The composition and heating values for all the products including the original feedstock

used in the pyrolysis experiment are displayed in Table 1. Notice that the standard

proximate analysis was not performed for the condensate, since it was not regarded as

applicative. The biomass analysis reveals no surprises and falls within similar values

which can be found in tables and databases (for example [11]) for biomass. For the

charcoal; since the entire proximate analysis is normalized and the moisture content is

low; the corresponding fixed carbon content is quite high. However, if the moisture

content is adjusted to 15%, which is the upper limit for an Elkem charcoal the fixed

carbon content is reduced to roughly 72%, which is still well within the given process

requirements (>60%). It is also worth mentioning that the 2% moisture content in the

charcoal from the experimental campaign is more than likely absorbed humidity (from

surrounding air) from when the sample was handled. The obtained condensate contains

33% moisture which is slightly higher than typical values reported for fast pyrolysis

oils which are around 25% using different types of fast pyrolysis technologies [12].

Table 1.

Proximate and ultimate analysis and heating value of the original feedstock used in

the pyrolysis experiments together with the analysis of the obtained charcoal, condensate and

gas.

Pine wood chips Charcoal Condensate Gas

Moisture

25.4

2.0

33 -

Ash

0.2

0.8

0.002 -

Volatiles

61.2 14.5

-

-

Fixed carbon

13.2 82.8

-

-

C

53.4 86.9

35.5 36.7

H

6.4

2.8

8.5 2.0

O

39.9 10.2

55.9 61.3

N

0.2

0.1

nd.

-

S (mg/kg)

67.7 172.0

nd. na.

Cl (mg/kg)

37.9 43.0

nd. na.

HHV

17.4 32.6

15.3 7.9

Proximate analysis (as received wt-%)

Ultimate analysis (wt-%, solids as dry)

Higher heating value (MJ/kg )

4