Figure 3:

B- and P- removal factors with (R&D) and without purification of the eutectic

(POR) from ICP-OES measurements. To compare both processes the data points were

normalized by the median of the input MG-Si. Data are grouped into MG-Si (input), SP

(Single Pass in Al-Si), DP (Double Pass) and TP (Triple Pass).

The data show that after three passes in a solvent growth refinement 96.6% of the Boron

and 95.5% of the Phosphorus of the input MG-Si are removed. The removal of all other

impurities (e.g. transition metals) during the solvent growth happens simultaneously and

at a much higher removal rate than B and P. According to the actual specification Silicor

guarantees B

0.3ppmwt and P

0.74ppmwt. With the purification and recycling of

eutectics a significant reduction of these values is expected.

Developments on Al removal and final material quality

As already mentioned before, the solvent growth refining removes all impurities except

aluminum and the final removal of aluminum is most essential and takes place in a

directional solidification. This process step was engineered to be carried out with large

quantities in simple molds and is assisted by pure liquid glass-flux on top of the silicon

melt [2]. In Figure 4 SIMS measurements of the final Al content in finished good is

compared for directional solidification with and without the use of a glass-flux. Using the

flux allows a control of the Al at levels equal and below 0.2ppmwt which is a

concentration that doesn’t degrade the performance of a solar cell made from the material

[4].

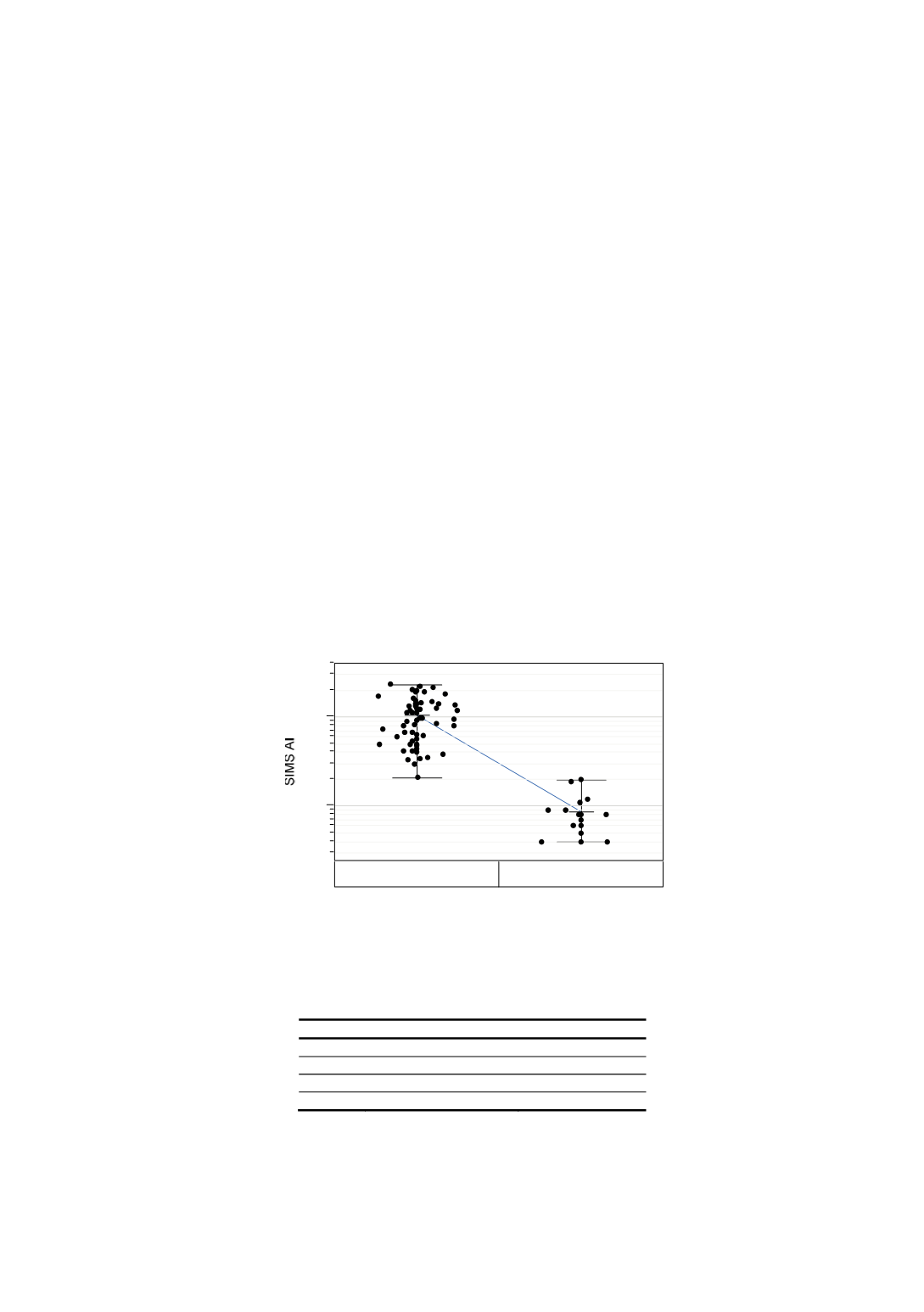

Figure 4:

SIMS measurements of the final Al content in finished good is compared for

directional solidification with and without the use of a glass-flux.

Table 1 presents some ICPMS measurements on transition metals in finished good solar

grade silicon from Silicor’s purification process.

Table 1:

ICP-MS measurements of transition metals

Element Concen-tration [ppba]

N Purity

Ti

3.091

>8N

Cr

0.025

>10N

Fe

1.664

>8N

Ni

1.133

>8N

$ QR IOX[

% IOX[

12