The different applications finally reflect the properties of pyrogenic silica, i.e. large

surface area and fractal-like structure of the sub-micron sinter aggregates. In the

following section, some applications are discussed in more detail.

Reinforcement of Silicone Elastomers

Silicone elastomers are widely used in automotive, food and household, energy

transportation and distribution, medical, etc. [33].

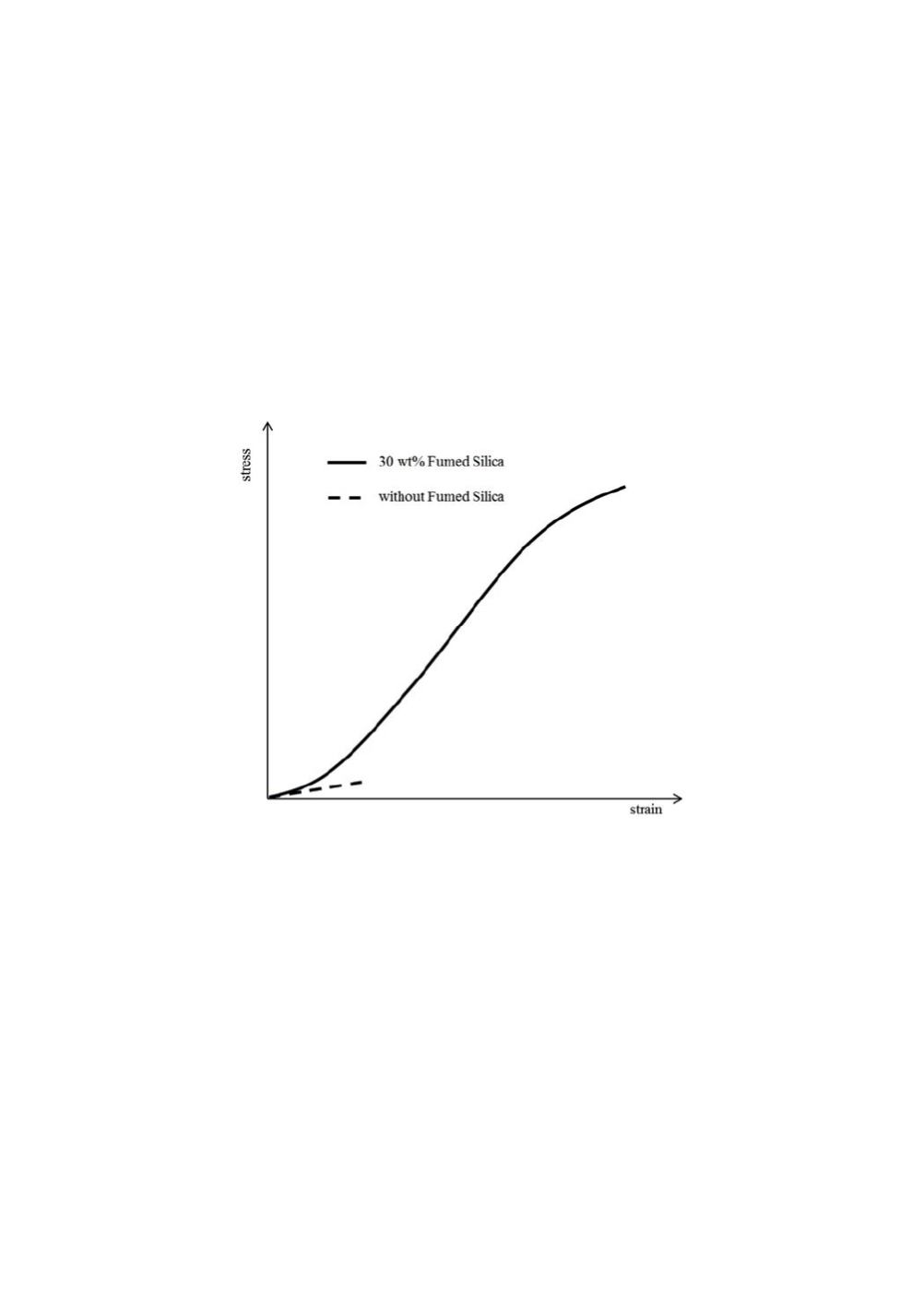

Silicone elastomers consist of chemically cross-linked siloxane polymers and ca. 30

wt% of silica. The silica particles act as reinforcing fillers, i.e. they increase strength

(moduli) and improve the ultimate properties (deformation and stress at break) of

silicone elastomers. Fig. 14 schematically depicts the stress-strain behaviour of silicone

elastomers with and without reinforcing silica.

Figure 14:

Schematic stress-strain behaviour of silicone elastomers with and without

reinforcing silica.

By using pyrogenic silica, modulus, deformation at break, and stress at break can be

increased by at least ca. one order of magnitude [2]. Despite the maturity of these

materials, the exact mechanisms of silica reinforcement are still not fully understood.

However, it is generally accepted that the inclusion of particles with a high modulus, as

well as particle-polymer interactions and particle-particle interactions are important

factors to improve the mechanical properties of elastomers [34-36]. In order to improve

particle dispersion and modulate particle interactions the silica surface is often

chemically modified, i.e. the surface silanol groups are reacted with reactive silanes or

siloxanes to form stable Si-O-Si bonds. This can be achieved by in-situ silane treatment

during compounding of silica into the gum base. An widely used silane modifier is

hexamethyldisilazane ((CH

3

)

3

Si-N(H)-Si(CH

3

)

3

)[2].

119