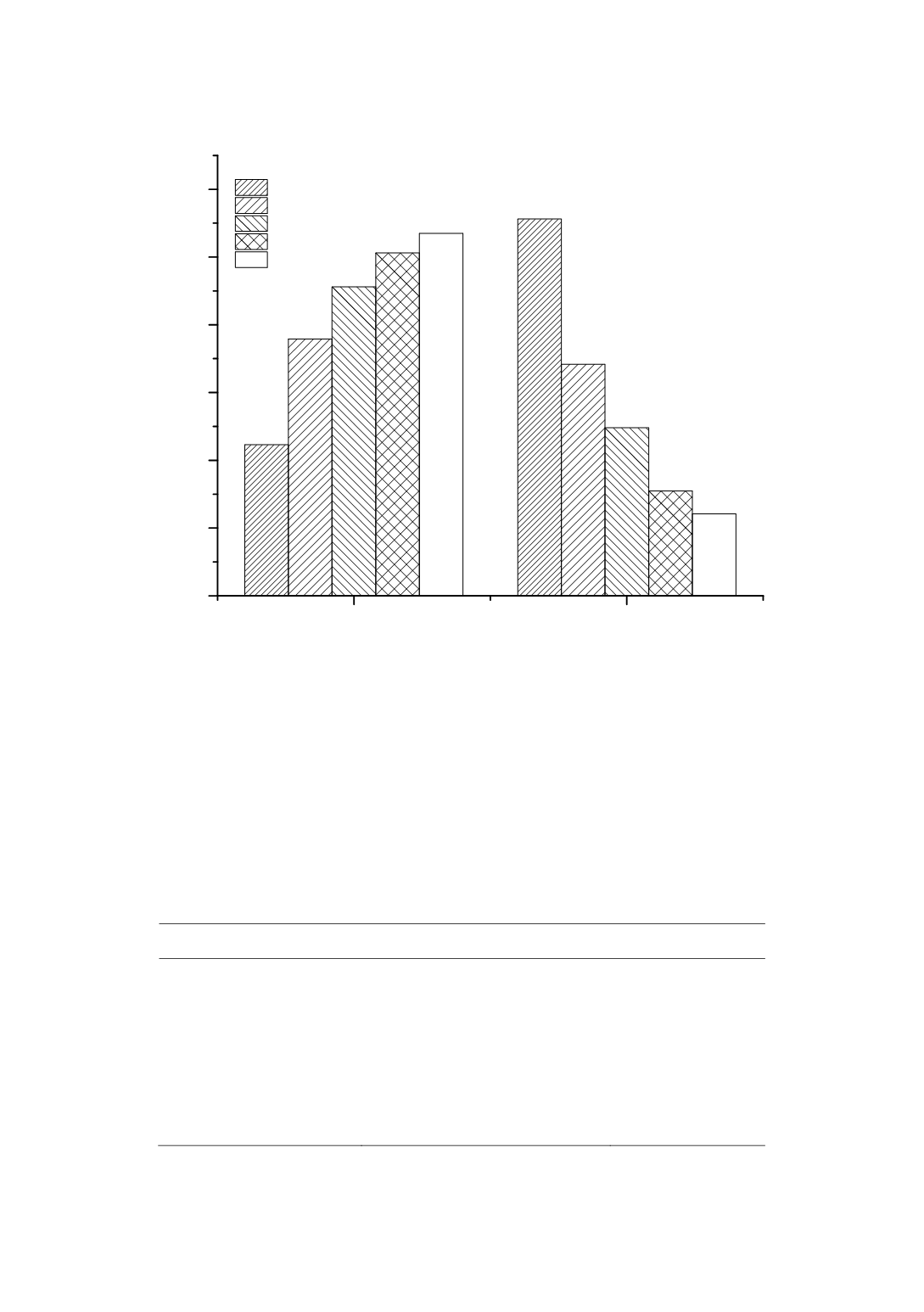

Figure 13:

Laser light diffraction data of an aqueous dispersion of pyrogenic silica of

300 m

2

/g SSA stirred at 3000 rpm (internal stirrer of Mastersizer 3000) for different

periods of time.

Under these mild shear conditions, the particle size distribution shows a bimodal

distribution with one mode in the nm-range and a second mode in the μm-range. With

increasing stirring time, the sub-micron mode increases in intensity. The intensity of

the coarse particle peak (μm-mode) strongly decreases.

Applications of pyrogenic silica

Main industrial applications of pyrogenic silica are summarized in table 1.

Table 1:

Main industrial applications of pyrogenic silica.

Application

desired effect

dosage / wt%

reinforcing filler

Improving mechanical properties of

silicone elastomers

ca. 30

rheological additive

Flow control of sealants, adhesives,

and coatings

1 – 10

thermal insulation

High and low temperature insulation

ca. 80

anti-blocking additive

Free flow of adhesive powders

0.05 – 1

charge regulation additive

Charge regulation of toner particles

ca. 0.5 – 1

pharmaceutical excipient

Improved powder handling, tabletting,

and tablet disintegration

ca. 1

submicron mode

μm-mode

0

1

2

3

4

5

6

volume density [%]

12 min stirring

24 min stirring

36 min stirring

48 min stirring

60 min stirring

118