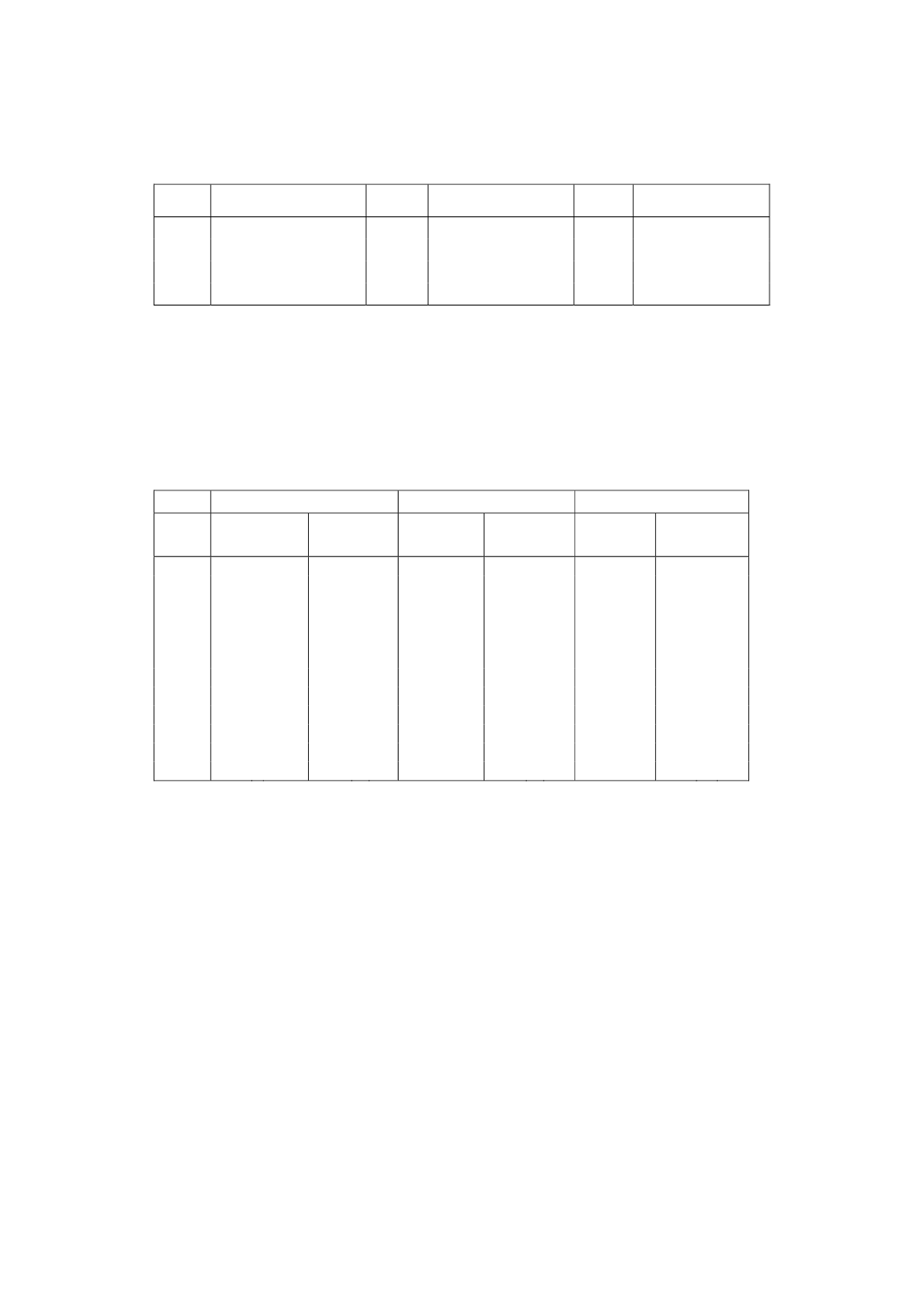

Table 4

Minima of LOQ (k = 10) calculated from calibration functions of multi-element

standard solutions with 4 mg g

-1

Si, all analytical wavelengths measured in axial viewing

element

wavelength /

nm

w

LOQ

/

μg g

-1

element

wavelength /

nm

w

LOQ

/

μg g

-1

element

wavelength

/ nm

w

LOQ

/

μg g

-1

B

182.641

2.96

Ca

317.933

15.2

Fe

239.556

4.13

Mg

285.213

1.20

Ti

334.941

0.71

Ni

216.556

1.47

Al

308.215

3.92

Cr

205.552

1.79

Cu

324.754

1.83

P

185.942

5.00

Mn

257.610

0.31

Zr

349.621

0.46

Comparison with certified reference materials

Table 5 compares the values of the certified reference materials (SRM 57b IPT134,

IPT135) with the analytical results obtained by the new microwave-assisted digestion

procedure with ICP-OES measurements against a matrix matched calibration (MMC).

Table 5:

Comparison between impurity contents in certified reference materials and results

obtained by the new developed microwave-assisted procedure measured in high-silicon

matrix and quantified by MMC; n = 5; all units are μg g

-1

NIST SRM 57b

IPT 134

IPT 135

element

certified

value

found value

certified

value

found value

certified

value

found value

B

(12.5

±

2.1)* 13.4 ± 0.6

not certified

6.6 ± 0.8

not certified

7.4 ± 0.5

Mg

not certified

2.4 ± 0.2

48

±

3 49.9 ± 0.9

12

±

1 11.9 ± 0.2

Al

1690

±

220 1551 ± 53

850

±

30

842 ± 23 450

±

30 377 ± 16

P

16.3

±

1.5 15.6 ± 1.2

33

±

2 31.0 ± 2.3

27

±

1 24.3 ± 2.1

Ca

22.2

±

4.5 21.0 ± 6.9 1020

±

30 1026 ± 21 110

±

10 113 ±

7

Ti

346

±

49

329 ±

7

97

±

4

100 ±

2 113

±

4 119 ±

2

Cr

17.3

±

3.3 14.7 ± 0.4

11

±

1

9.0 ± 0.4

6

±

1

4.9 ± 0.1

Mn

78.2

±

7.2 70.0 ± 1.5

113

±

5

101 ±

1

70

±

3 65.5 ± 0.4

Fe

3400

±

60 3294 ± 45 2900

±

100 2828 ± 26 1250

±

30 1280 ± 16

Ni

15.3

±

1.7 15.6 ± 0.7

6

±

1

4.9 ± 0.6

5

±

1

3.6 ± 0.3

Cu

17.2

±

5.8 22.8 ± 0.5

14

±

2 15.8 ± 2.3

8

±

1

8.6 ± 0.4

Zr

17.8

±

0.6 17.5 ± 0.4

not certified

5.8 ± 0.1

not certified

4.4 ± 0.1

* in 2015 a new certified value for boron was published from NIST: (14.43 ± 0.27) ppm

According to the International Conference of Harmonization [24] two analytical

values are in agreement if their distance does not exceed ± 10%. However, this

approach was considered as impractical in the present case since the confidence

intervals for some of the certified element contents are well above 20%. Therefore,

the assessment of conformity between the found and certified values, including their

confidence intervals, was done in accordance to the t-Student test. The precision is

interpreted as repeatability that should be significantly less than 5% for n

3

analyses.

For all investigated silicon samples the determination of metal impurities in the

high-silicon and acid matrices turned out to be uncomplicated. Only for low-calcium

concentrations (NIST 57b) a reduced repeatability was found, which was already

indicated in the broad confidence interval of the certified value. In previous studies, it

was found that the decreased repeatability due to low calcium levels can be traced

back to a blank value problem [10].

Special attention was given to the validation of the boron contents. The certified

boron content of SRM 57b was derived from measurements using two different

methods. While the solid analysis by PGAA provided a boron content of

102