increased to 80°C within 3 min and held for 20 min. Finally, the vessels were linearly

heated over 5 min to 120°C, with a holding time of 30 min. After cooling the sample

the total mass of the sample mixture was noted again in order to determine the mass

loss caused by escaping reaction gases during digestion. The digestion solution was

directly used without further treatment to prepare sample solutions for measurements.

A digestion solution of electronic-grade silicon (eg-Si) acts as method blank.

Sample preparation and ICP-OES measuring conditions

At first the sample was scanned using ICP-OES to determine the approximate

element contents. For this procedure the digestion solution was diluted with a mixture

of HF/HNO

3

(each 1% (v/v)) so that the content of the dissolved sample is

approximately 2 mg g

-1

. The method blank solution was used to prepare the scan

standard which was diluted to the same content of dissolved silicon and spiked with a

multi-element standard with typical element concentrations.

With the knowledge of the approximate element contents the sample solution was

diluted with HF / HNO

3

(1% (v / v)) to match the contents of the dissolved sample

between 1 mg g

-1

and 4 mg g

-1

depending on the scanned element contents. A multi-

element standard stock solution was prepared in such a way that the element

concentrations matched to the ratios of the impurity element concentration obtained

by the ICP-OES scan. Aliquots of this standard stock solution were added to a

constant aliquot of the method blank solution with a silicon content comparable to the

sample solutions. A 6-point calibration was made at equidistant intervals so that the

middle of the calibration ranges represents the element concentrations of the sample.

To determine the 12 major impurity elements (B, Mg, Al, P, Ca, Ti, Cr, Mn, Fe,

Ni, Cu, Zr) an (ICP-OES) with duo-view option (iCap 6500 DUO, Thermo Scientific,

Germany) was used. The HF-resistant sample introduction system was equipped with

a parallel path nebulizer made of PEEK (MiraMist, Burgener Inc.), a cyclonic PTFE

spray chamber (Glass Expansion) and a ceramic injection tube (ibid.). The plasma and

integration parameters are listed in Table 1.

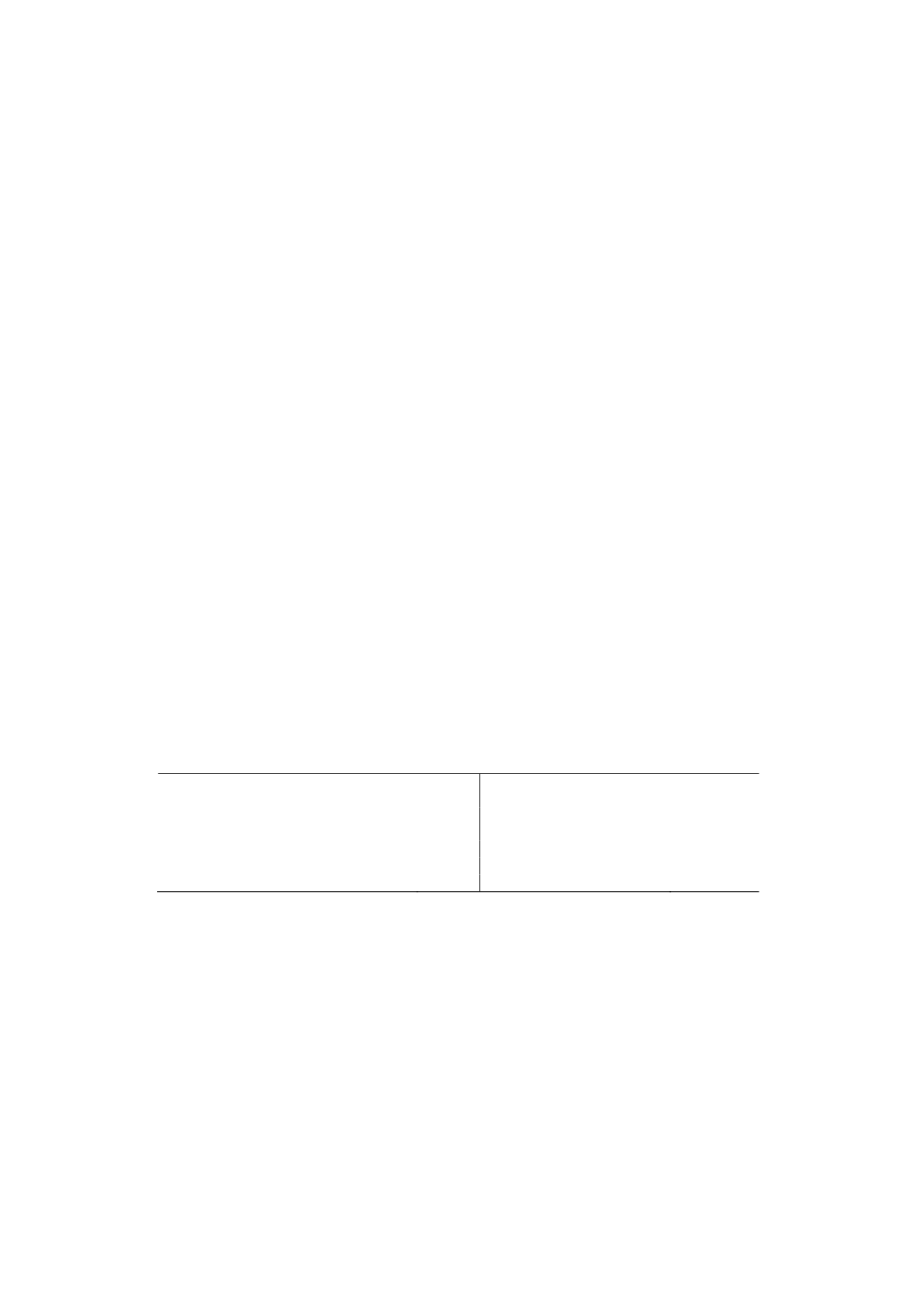

Table 1:

Instrumental and integration conditions of the ICP-OES

RF incident power [W]

1150

Plasma viewing mode

axial or axial

and radial

Plasma argon flow rate [L min

-1

]

12

Maximum averaging time [s]

Auxiliary argon flow rate [L min

-1

]

0.5

UV (axial / radial)

20 / 15

Nebulizer argon flow rate [L min

-1

]

0.5

Vis (axial / radial)

10 / 5

Sample uptake rate [U min

-1

]

50

Subarry readout

Inner diameter of the torch injector [mm]

2

width

20

Selection of element characteristic emission lines for ICP-OES analysis was

carried out after detailed checks of interferences with other analyte elements and with

silicon as the major matrix component. Finally, the selection was made according to

the criteria of low interferences, high intensities and low signal-to-background ratios.

In order to uncover unexpected spectral and non-spectral interferences, at least 3

emission lines are measured for each element. The most suitable analytical emission

wavelengths for the measurement in high silicon matrices are summarized in Table 2.

The Ar emission at 404.442 nm is used for monitoring the plasma stability, and the Si

emission at 390.552 nm to check the consistency of the matrix.

98