Al

6

CaFe

4

Si

8

. Increasing again the amount of Al, leads to the formation of Al

3

FeSi

2

instead of FeSi

2

which is beneficial for the reaction between silicon and methyl

chloride. The presence of Ti will not only forms TiSi

2

(and usually FeSi

2

Ti but the

model seems not very accurate for this compound) but also significantly increase the

formation of Al

3

FeSi

2

(+20% from alloy 5 to 6). Alloy 7 shows the effect of Fe on the

different compounds in the presence of Ti.

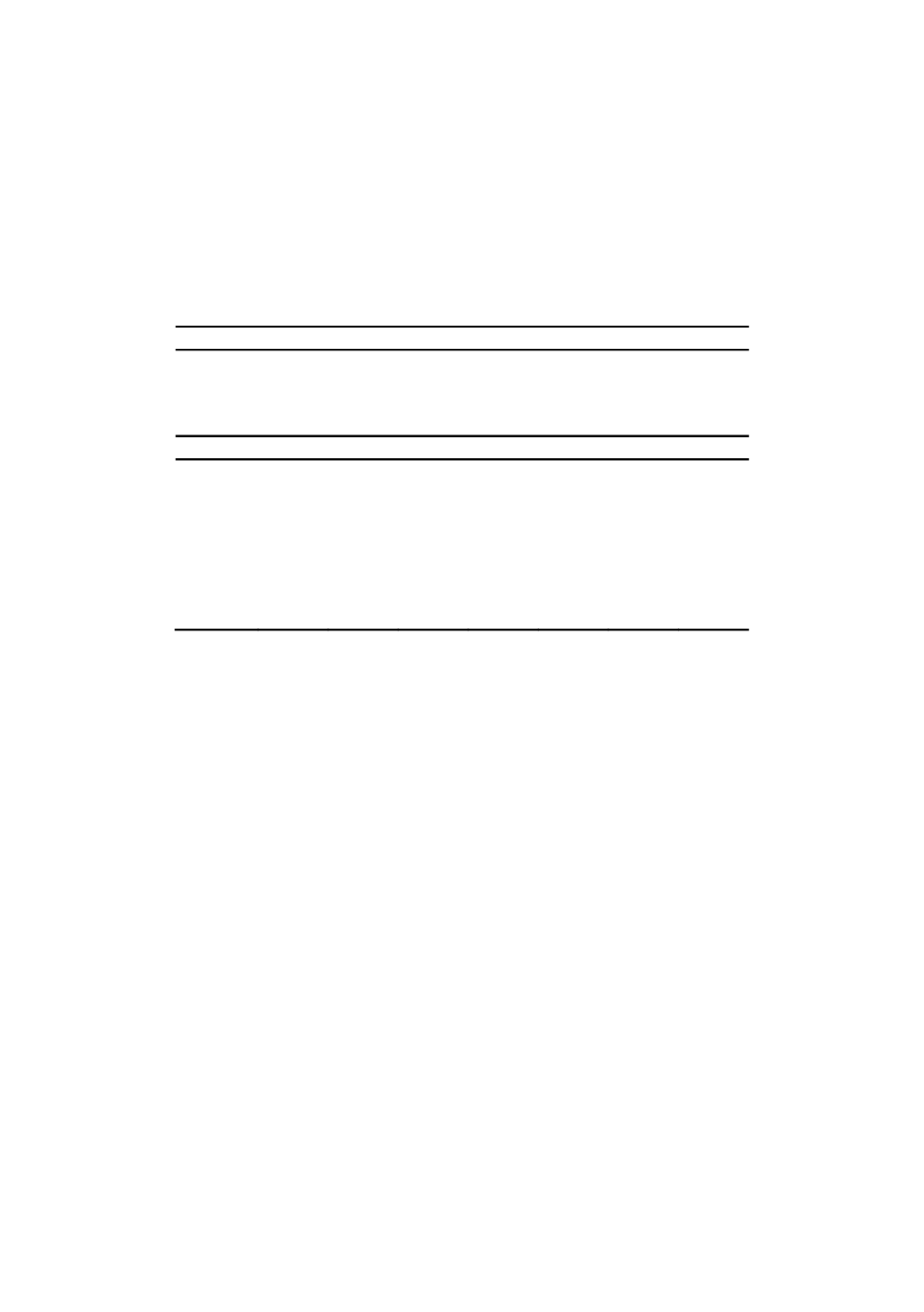

Table 1.

Effect of the alloy composition on the amount and type of intermetallic compounds

ůĞŵĞŶƚ

ůůŽLJ ϭ

ůůŽLJ Ϯ

ůůŽLJ ϯ

ůůŽLJ ϰ

ůůŽLJ ϱ

ůůŽLJ ϲ

ůůŽLJϳ

ů

Ϭ͘ϰϬ й Ϭ͘ϲϬ й Ϭ͘ϱϱϬ й Ϭ͘ϳϬ й Ϭ͘ϴϬ й Ϭ͘ϴϬ й Ϭ͘ϴϬ й

Ă

Ϭ͘ϲϬ й Ϭ͘ϰϬ й Ϭ͘ϯϰϬ й Ϭ͘Ϯϵ й Ϭ͘ϯϬ й Ϭ͘ϯϬ й Ϭ͘ϯϬ й

&Ğ

Ϭ͘ϯϬ й Ϭ͘ϯϬ й Ϭ͘ϰϬ й Ϭ͘ϯϬ й Ϭ͘ϯϬ й Ϭ͘ϯϬ й Ϭ͘ϰϵ й

dŝ

Ϭ͘ϬϮ й Ϭ͘ϬϮ й

WŚĂƐĞƐ

^ŝ

ϵϳ͘ϱϰ й ϵϳ͘ϴϱ й ϵϳ͘ϴϱ й ϵϴ͘Ϭϴ й ϵϳ͘ϵϲ й ϵϳ͘ϵϭ й ϵϳ͘ϱϴ й

&Ğ^ŝϮ

Ϭ͘ϲϳ й Ϭ͘ϰϭ й Ϭ͘ϰϵ й

Ă^ŝϮ

Ϭ͘ϳϳ й

ůϮ Ă^ŝϮ

ϭ͘ϬϮ й ϭ͘ϰϭ й ϭ͘ϭϰ й Ϭ͘ϴϵ й Ϭ͘ϵϯ й Ϭ͘ϵϰ й Ϭ͘ϴϬ й

ůϯ&Ğ^ŝϮ

Ϭ͘Ϭϱ й Ϭ͘Ϭϳ й Ϭ͘Ϭϵ й Ϭ͘Ϭϲ й

ůͲĞƵƚĞĐƚŝĐ

Ϭ͘ϭϱ й Ϭ͘Ϯϯ й Ϭ͘ϮϮ й Ϭ͘ϭϰ й

dŝ^ŝϮ

Ϭ͘Ϭϱ й Ϭ͘Ϭϱ й

ůϲ Ă&Ğϰ^ŝϴ Ϭ͘ϬϬ й Ϭ͘ϯϰ й Ϭ͘ϱϮ й Ϭ͘ϴϯ й Ϭ͘ϴϭ й Ϭ͘ϴϬ й ϭ͘ϯϳ й

The presented analysis illustrates how Sistruc can be used to quickly test different

compositions, predict trends and also provides quantitative estimations.

Conclusion

A user-friendly microstructure model, Sistruc, has been developed to predict the

formation of intermetallic compounds in metallurgical silicon during solidification. The

model has been recently upgraded, calibrated and further developed. The model is

based on a simplified approach. The model parameters have been calibrated with

literature data for binary and ternary systems. The model has been applied to study the

effect of the alloy composition on the appearance of specific phases.

As a conclusion, the current version of Sistruc is a good tool for industrial optimization

of metallurgical silicon composition to reach specific requirements. While the

calibration through literature phase diagram data is a good starting point, validation by

comparison with solidification experiments is a necessary step to assess the predictive

power of the model. Further improvements of the model are underway and will focus

on the effect of solidification rate by accounting for finite diffusion in combination with

a grain size prediction model.

Acknowledgments

The funding of Elkem and the Norwegian Research Council through the CORSICA

project is greatly acknowledge.

81