had a thickness of approximately 5 mm. The external layers of carbides and oxides

have been removed by grinding with SiC-paper.

2.3 EPMA, EDS and BSE analysis

EPMA (Electron Probe Micro-Analysis) has been performed on the treated and the

annealed samples by using a JEOL JXA-8500F. The work has been performed

together with Morten Raanes at the Department of Material Science and Engineering

at NTNU. Points showing different contrast were selected to detect the relative mass

percentage of Fe, Al, Si, Ca, Ti, Ba and Cu. It was possible to spot the correct phase

thanks to the information collected from literature [3,17].

BSE images were chosen to analyse further the three samples. A Hitachi SU-6000

FE-SEM was used. Each image has a different scale according to the size of the

intermetallic, but a resolution of 2560x1920 pixel was kept. The EDS-spectra detected

the elements present in the phase in chosen single points. The phase percentage in the

intermetallics was calculated by using the software ImageJ

®

. Extension of areas with

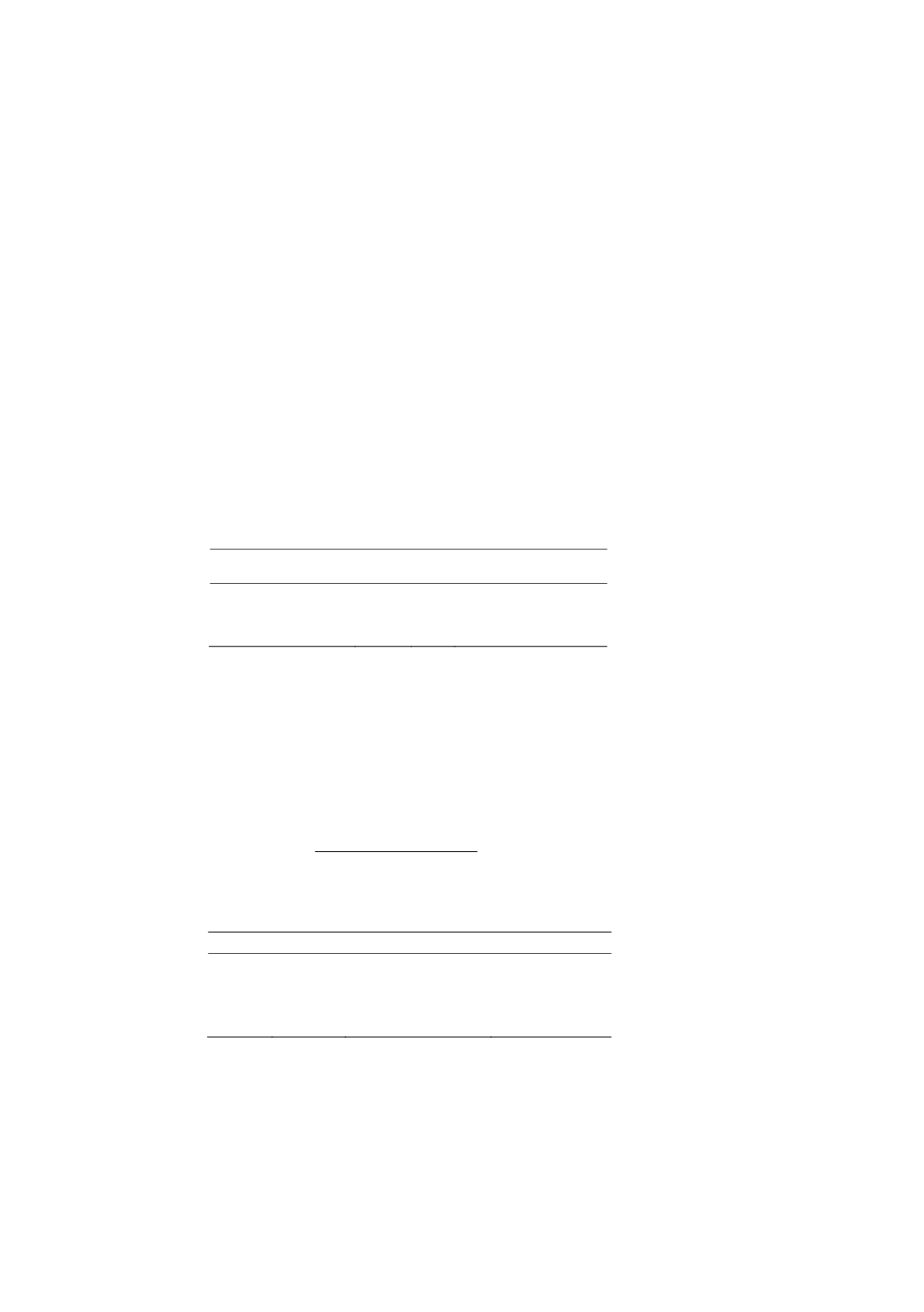

different contrast have been measured. Table 2 resumes the number of intermetallics

analysed with each method for each sample.

Table 2

: Number of particles analysed and sum of their extension

Sample

EPMA EDS Total intermetallic area

per sample (

ȝ

m

2

)

Untreated

0

54

113 633

600°C 17h Treated

29

31

166 507

1200°C 17h Annealed 21

33

171 761

3. Results

3.1 XRF and SiStruc

®

analysis

Table 3 gathers the percentages of impurities in the three cases. The values for the

sample annealed at 1200°C for 17 hours are the average of the five slabs. An

approximate composition of the untreated material is presented due to industry's

restrictions. The relative variation is expressed by the following formula:

Relative variation

=

untreated

untreated

annealed

X

X

X

%

%

%

−

(1)

Table 3

:

Average value of the %wt. of Fe, Al, Ca, Ti found after XRF analysis

Element Untreated 1200°C 17h Annealed Relative variation

Fe

0.40

0.27

-20%

Ca

0.05

0.04

-35%

Al

0.15

0.12

-10%

Ti

0.05

0.02

-25%

Inserting these data in SiStruc

®

gave expectations about the content and the

composition of the phases present in each sample. Table 4 resumes the results of the

SiStruc

®

analysis and the relative variation between the two samples. The percentage

in brackets next to the %wt expresses the mass fraction of the phase if only the

intermetallic phases were considered. The relative variation is expressed by Eq. (1).

87