temperature is computed from the initial concentration. Then at each solidification step

(except last step), the following algorithm is employed:

1.

Store the starting concentration

2.

LOOP to find the appropriate amount of Si phase (sub-step is set at 1% of the

current cell size)

a.

Compute the liquid concentration assuming a partial solidification of the

cell without any precipitation based on the starting concentration

b.

LOOPs for precipitation

i.

Test if precipitation occurs for each particle based on this "trial"

liquid concentration

ii.

If precipitation occurs, compute the composition and amount of

precipitate that forms (applying the mass balance) until the

solubility limit is reached

iii.

Update the "trial" liquid concentration with the new liquid

concentration for that solubility limit

iv.

Go to the next particle type

c.

Test if the total amount of phases formed (including Si) is close to the

mass of the cell, and if not go back to Step 2 and increase the amount of

solidifying Si

3.

From the previous steps we have now a list of particles that precipitate with their

compositions and the precipitated amount. This amount corresponds almost to

the mass of cell (>90%), therefore only a limited scaling is required.

User interface

Sistruc model is programmed in Free Pascal to allow easy build-up of user interfaces.

The code structure is divided between handling user interaction and a mathematical

core where the equations are solved. A modular approach has been used to enable

further development of the code and introduction of more advanced models.

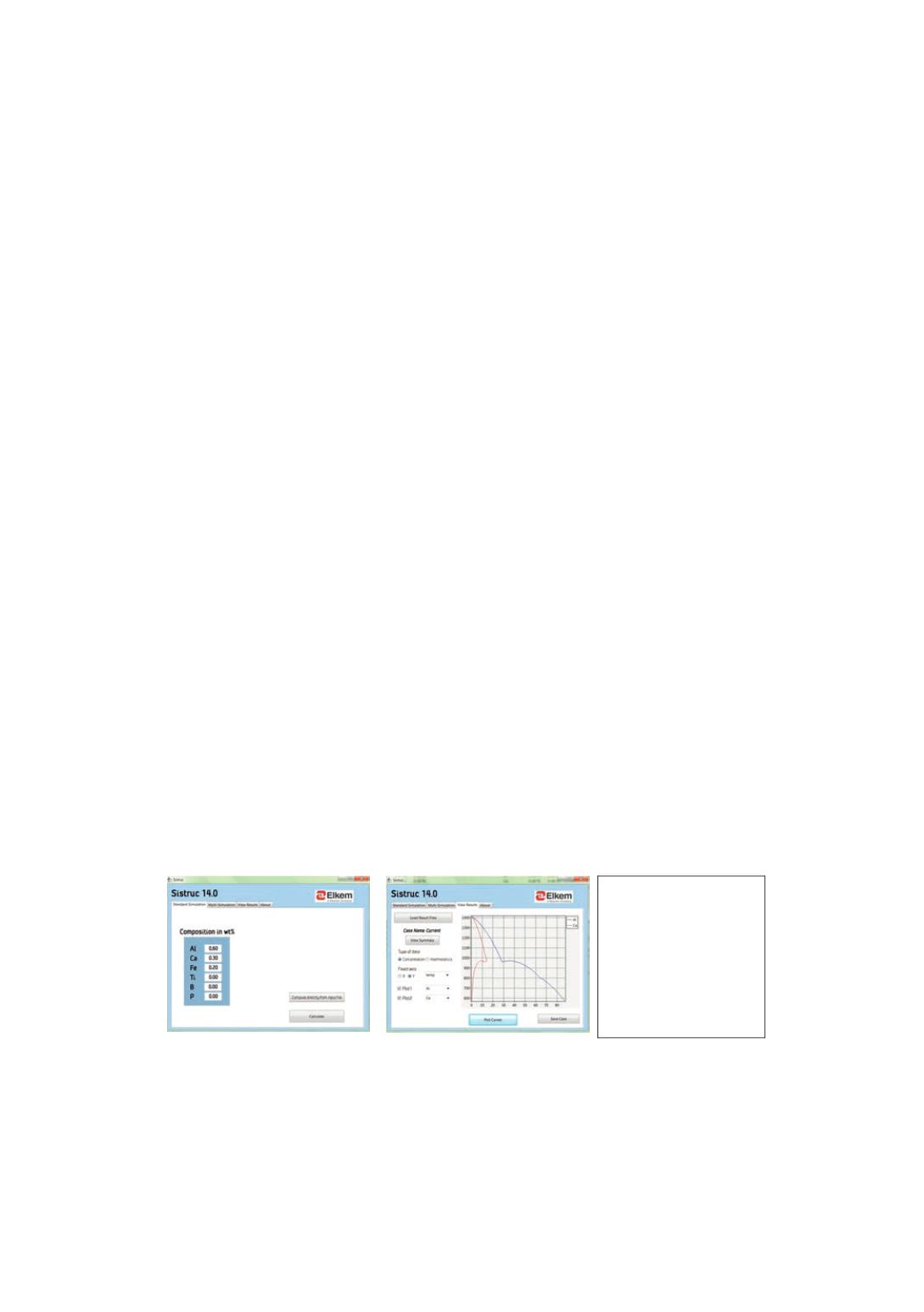

The user interface, as illustrated in Figure 1, is extremely simple when using the default

options. The user needs only to enter the alloy composition and run the calculation. The

program will then generate the history of temperature, liquid concentration, amount of

phases, etc., to be plotted directly in the graphical user interface. Moreover, text files

are generated for visualization and post-processing in a spreadsheet.

*** Initial composition in wt%

Element Alloy1

Al 0.600%

Ca 0.300%

Fe 0.200%

*** Average phases amount in

the grain in wt% ***

Si-solid 98.337%

Al-eutectic 0.087%

Al3FeSi2 0.028%

Al2CaSi2 0.992%

Al6CaFe4Si8 0.556%

Figure 1.

User-interface and microstructure summary output.

Additional options can be enabled through the addition of specific keywords in the input

file. A tool is also available to run simultaneously a set of batch simulations for direct

comparison of ranges of compositions. This interface will be extended to include

78