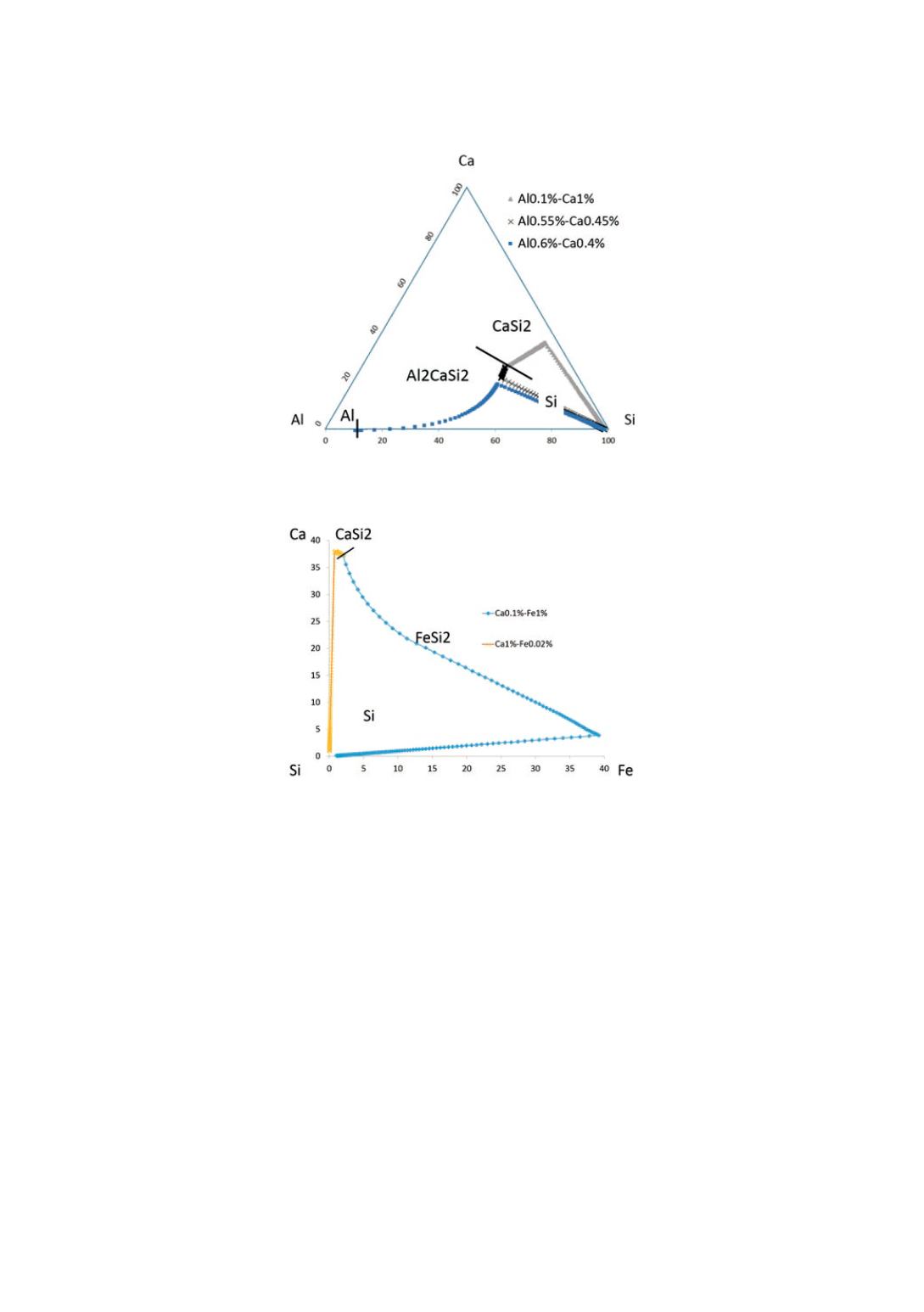

Figure 3.

Computed solidification path for three silicon alloys with 0.1%Al-1%Ca, 0.55%Al-

0.45%Ca and 0.6%Al-0.4%Ca

Figure 4.

Computed solidification path for a silicon alloy with 0.1%Ca-1%Fe and 1%Ca-

0.02%Fe

Additional work is planned to assess the predictive power of the model by comparison

with solidification experiments and DTA measurements.

Application

In order to illustrate the potential of this new tool, one case study is presented. The

study analyses the effect of alloy composition on the amount of the different

precipitated phases.

Sistruc is used to here to tailor the composition in order to obtain desired intermetallic

compounds for specific downstream process. The range of studied alloys is presented

in Table 1. The results show that the model is able to reproduce the well-known effect

of inverting the Al/Ca ratio between alloy 1 and 2 which leads to the disappearance of

CaSi

2

. Comparison of alloy 2 and 3 illustrates the effect of Fe content on the amount of

80