Part of this is due to the fact that the

convective heat transfer

of oxygen is a function

of the

velocity of the gas

through the pipe/lance. The ducts in the Trefimet lance will

result in increased gas velocity as the flow is the same (oxygen can be regarded as

incompressible at the speeds in question, as the differences in density is negligible).

One can show that for a TR38 lance, this results in an increased cooling effect with

approximately 25%.

The more significant part of the decreased temperature of the Trefimet lance is due to

the increased heat transfer area caused by the steel ducts inside the lance vs. a plain

pipe. Using Newton’s Law of Cooling:

where we are interested in concluding how the cooling effect (Q) changes with the

change in heat transfer area (A). k is the convective heat transfer coefficient for steel

(~50 W/m2K) and

ȟ

T the temperature difference.

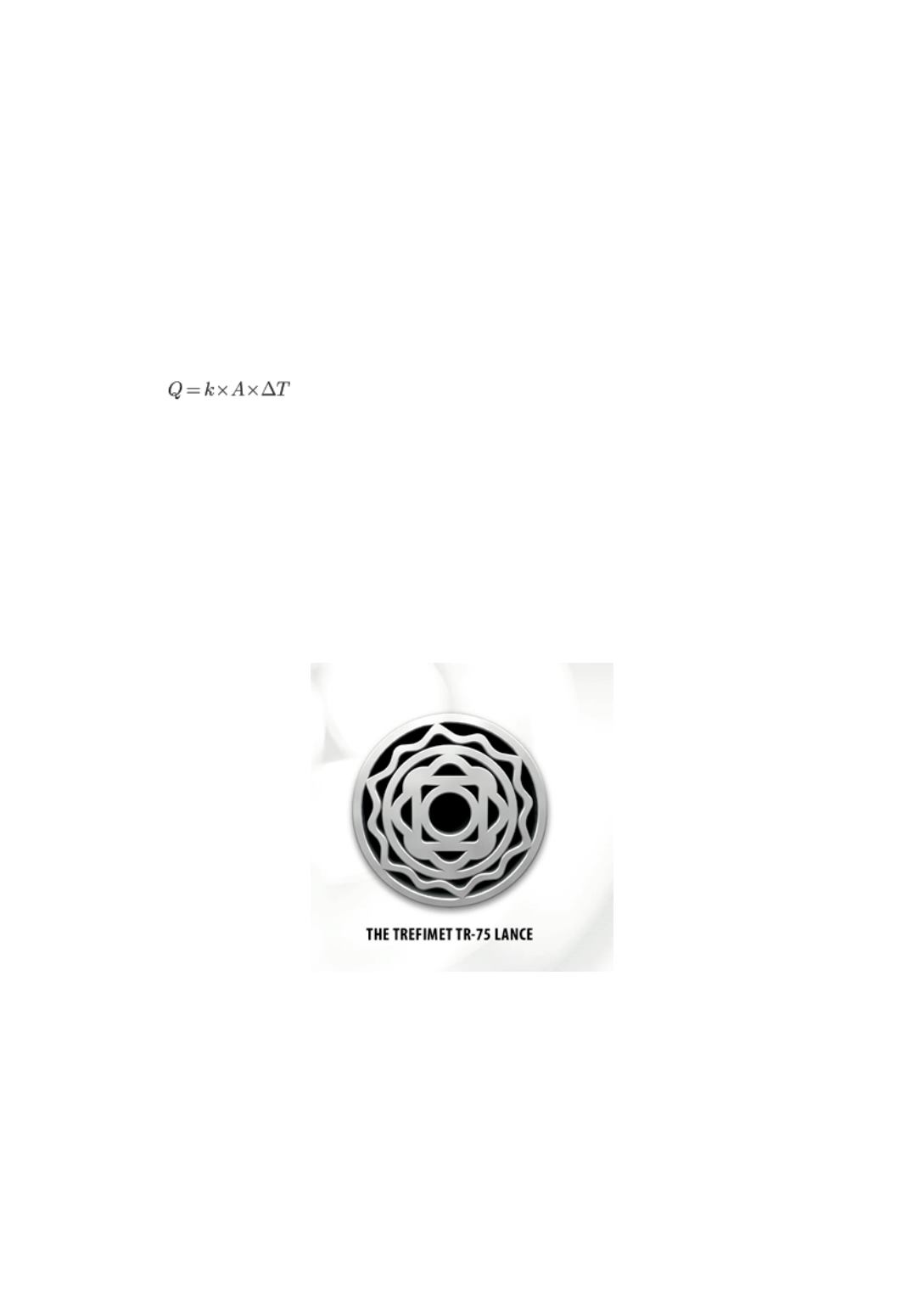

One can then show that the increase in cooling area between a standard steel pipe and

the TR38 lance results in an increased cooling effect of 500%. Looking at the TR75,

the increase will be even larger (Figure 9, The TR75 thermal lance)

The added cooling effect will result in less lance consumption, faster operation and

therefore significantly less Fe contamination to the Silicon.

Figure 9.

Showing the internal duct design of one very powerfull Trefimet model

Conclusion

Trefimet has managed to develop a patented and advanced oxygen lance design that

offers the following advantages to Silicon furnace operators:

• It focuses its energy on the attack point, resulting in more accurate perforations –

faster to operate and less damage to taphole. Less labor injuries inflicted.

61