Damage to the refractories is significant, which ultimately requires frequent taphole

maintenance. Needless to say, this maintenance has financial consequences for the

furnace operations.

Since the new advanced Trefimet lance generates its energy forward, no points behind

the tip of the lance are exposed to ignition temperatures. This fact dramatically lowers

the energy wasted on heating and cutting the lance itself and allows for most of the

energy to attack the target material. The increased effectiveness of the energy

generation of the new Trefimet lances makes them faster and more efficient than the

standard oxygen pipes.

Once ignited, these lances do not need material in front on which to bounce the heat

and oxygen; it will remain ignited under all conditions. This allows the operator to

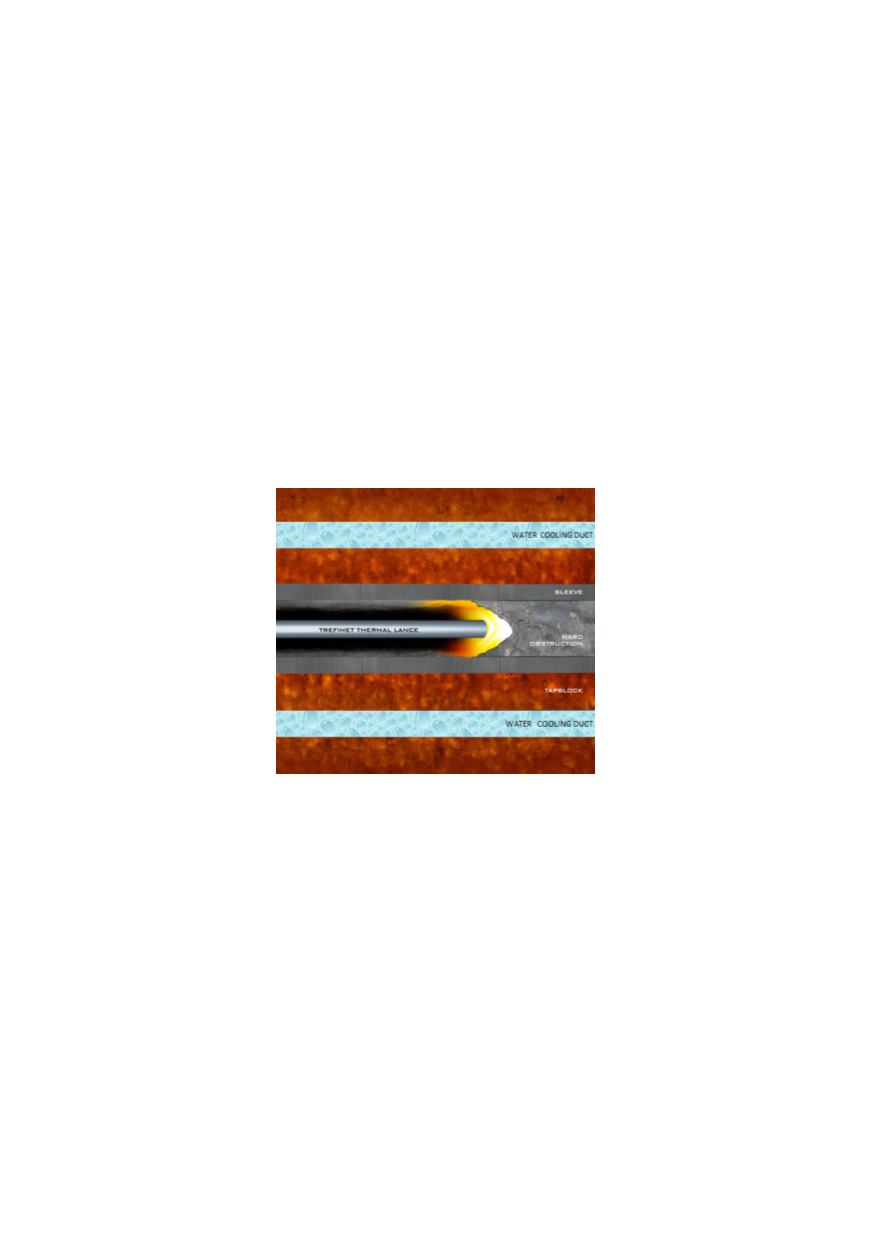

direct the lance in any direction he deems necessary. In Figure 8, a typical controlled

taphole opening is illustrated, causing no refractory damage.

Figure 8

. Trefimet lance in a taphole

Longer lasting lances due to “self-cooling” effect”

The many advantages operating a Trefimet lance in a Silicon furnace taphole has been

described in detail above. This reduces or at some furnaces, eliminates the need for

alternative taphole opening methods, many which are inefficient as well as unsafe.

In addition, the low temperature oxygen that flows through the many ducts of a

Trefimet lance, keeps the lance cooler, resulting in the lance better resisting the high

ambient temperature in front of the taphole. Historically, Si metal furnace operators

have been using ordinary steel oxygen pipes with ceramic coating, but as the lances

are operating slow, many lances are lost before they actually get the job done. This

also results in increased Fe contamination to the product. This is why the Trefimet

lance operates cooler than a plain steel pipe;

60