Department of Chemical Engineering

Annual Report 2015

29

GASSMAKS – IMPROVED PROCESS DESIGN AND

OPERATION OF NATURAL GAS CONVERSION

TECHNOLOGIES

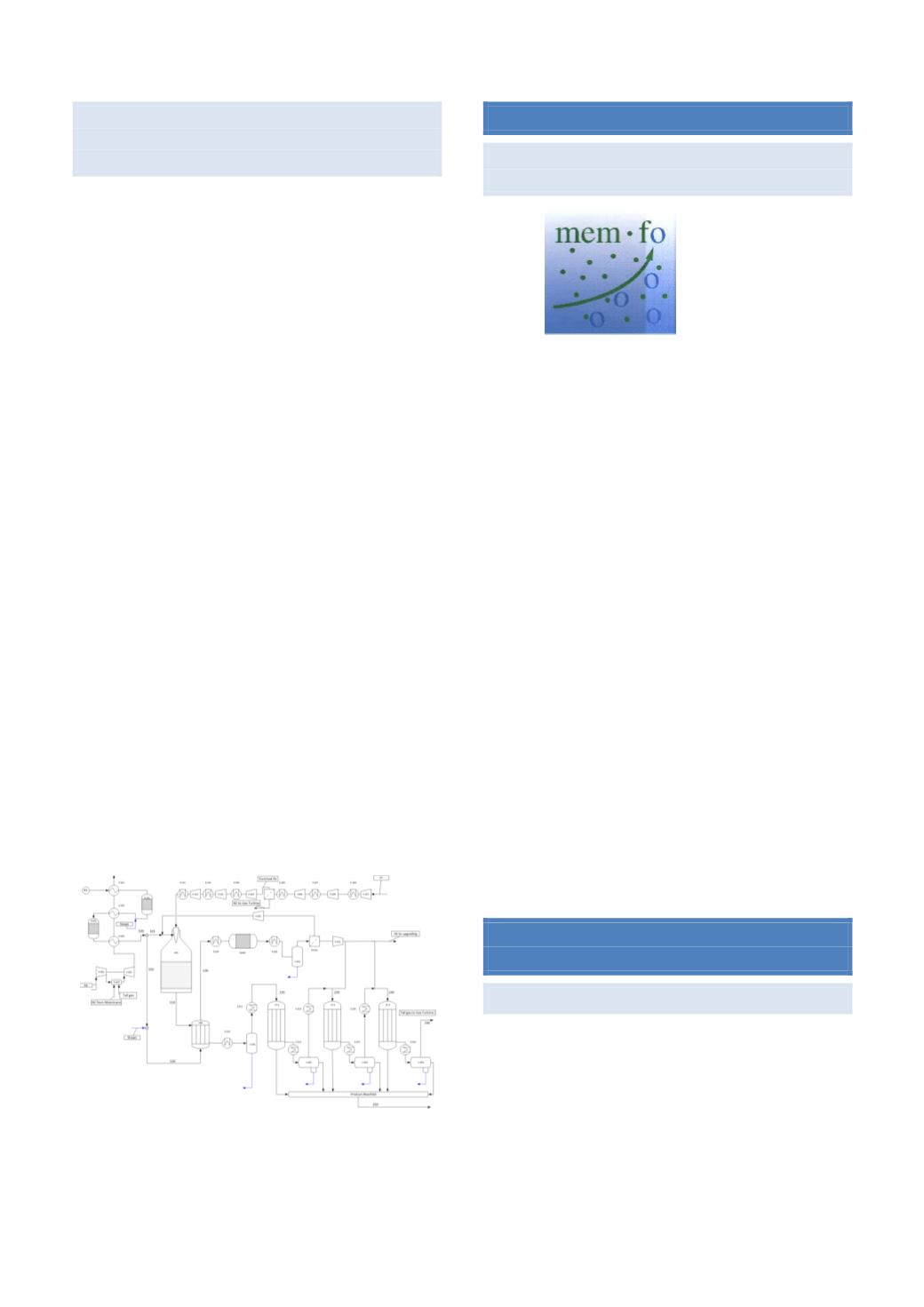

A novel process concept is proposed for converting

natural gas to liquid Fischer-Tropsch products. An

autothermal reformer with enriched air as oxidant is

applied for synthesis gas (syngas) production, and

because of the inert nitrogen a once-through Fischer-

Tropsch synthesis is the preferred option. In order to

maximize the syngas conversion and the production of

heavy hydrocarbons, a staged reactor path with

distributed hydrogen feed and product withdraw is

proposed. The hydrogen is produced by steam methane

reforming in a heat exchange reformer (gas heated

reformer), heat integrated with the hot effluent stream

from the autothermal reformer. Tail gas from the last

Fischer-Tropsch stage is sent to a gas turbine for power

production. The hot exhaust gas from the gas turbine is

used for natural gas preheating. The process is

autonomous in the sense that it is self-sufficient with

power and water, and therefore well suited for

production in remote locations such as a floating

production unit. The process concept is simple and

inexpensive since cryogenic air separation and fired

heaters are not required. For the Fisher-Tropsch

synthesis, both the conventional shell and tube fixed bed

reactors and microchannel reactors are considered and

compared. The carbon efficiencies for a once-through

synthesis are calculated to be 57 and 62 % for the fixed

bed and microchannel reactors, respectively. The part of

the energy that ends up in the product is 45 and 50 % for

the fixed bed and microchannel reactors. However, the

fixed bed alternative produces more energy as steam

and power for export.

Results from CO2SIM.

MEMBRANE RESEARCH

MEMBRANES FOR GAS SEPARATION AND

OSMOTIC PROCESSES

Memfo = Membran Forskning (Membrane Research)

The membrane research programs have extensive

activities on basic membrane material development, as

well as membrane gas separation processes, modelling

and simulations. The main focus for the research is CO

2

capture by membranes (from flue gas, natural gas

sweetening, biogas upgrading) and hydrogen recovery

from various mixed gas streams. In addition to this

energy focused gas applications, there is also ongoing

research on membranes for other gas mixtures and

liquid separation The membrane materials in focus are

various types of polymers, nano-composites, carbon

membranes, and modified glass membranes.

The group has several well equipped laboratories

available for the membrane research; both for

membrane material development as well as membrane

characterization. The membrane research on CCS is

especially strong, and completes the research on CCS

activities within the Environmental engineering and

reactor technology group.

The international network is extensive, with co-

operation both within EU-projects, USA, China, Japan,

the Nordic countries and Russia.

BRIEF DESCRIPTION OF SAMPLE GAS

SEPARATION PROJECTS

NORCEM-ECRA/NFR PROJECT

This is a project with pilot-scale demonstration of fixed-

site-carrier membranes for CO

2

capture from the flue gas

in Norcem cement industry by collaboration with DNV GL

and Yodfat Engineers. This project comprises two phases:

a feasibility phase and phase for execution. The feasibility

phase is to test and document the membrane

performance and durability over at least 6 months of

exposure in the flue gas in Brevik cement kilns, while