Department of Chemical Engineering

Annual Report 2015

25

The PBEs are solved accurately by efficient spectral and

spectral-element methods designed for this particular

purpose.

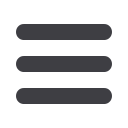

Flow pattern in a bubbling fluidized bed.

We are also investigating the performance of chemical

reactive systems like fluidized beds, fixed bed reactors

and agitated tanks. At present we are working with the

design of suitable reactors for sorption enhanced

reaction processes (SERP) like steam reforming with

absorbents for CO

2

. Moreover, we are performing

investigations of the chemical looping reforming and

combustion processes.

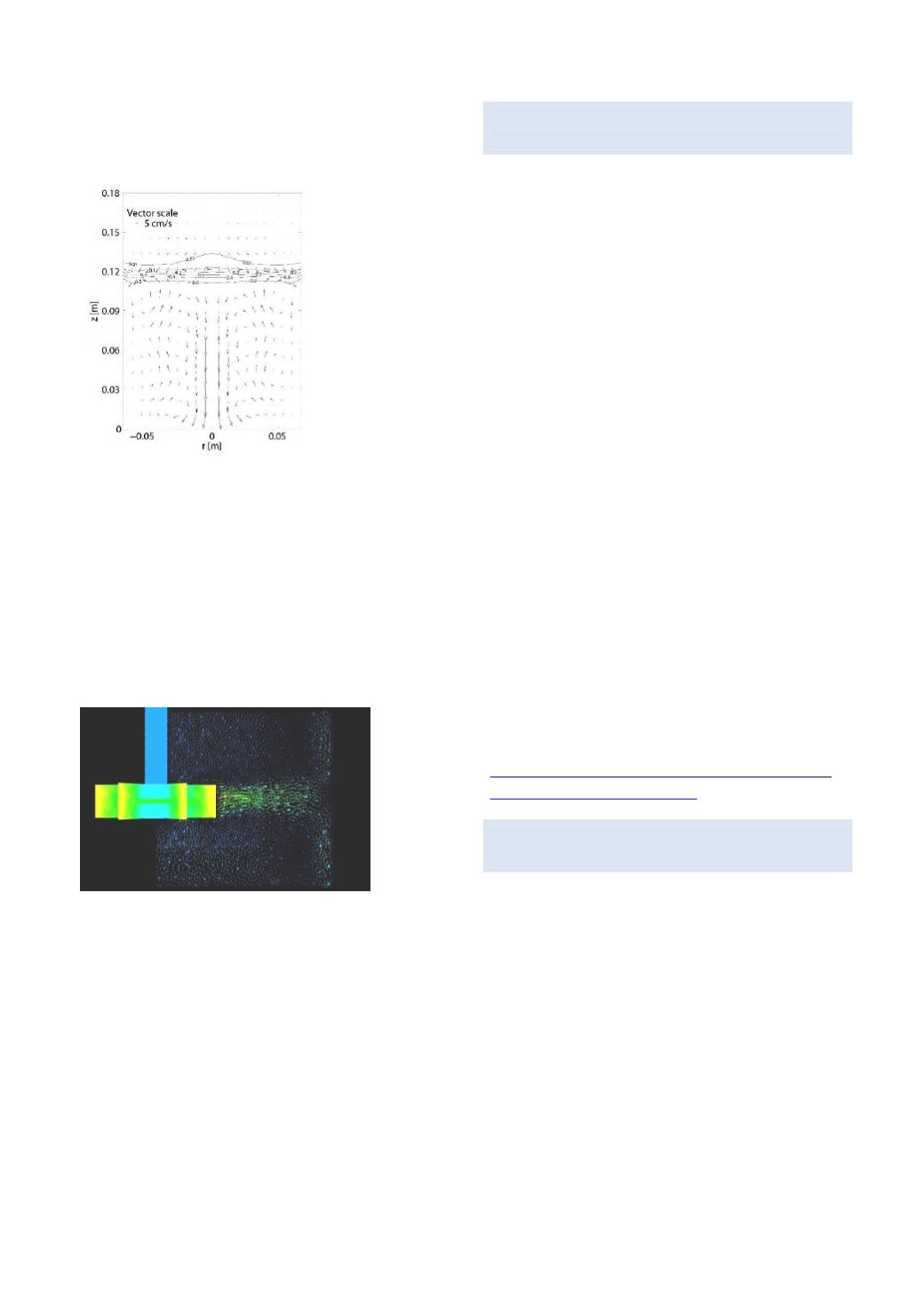

Simulation of the flow pattern from a turbine impeller.

The conventional 1D and 2D steady-state reactor models

are normally run on standard PCs whereas the more

computationally demanding dynamic 2D and 3D single

and multiphase flow simulations are run on the national

super-computers located at the university.

ADVANCED MODELING AND SIMULATION OF

CHEMICAL- AND BIOCHEMICAL REACTORS

The activity in this area is mainly founded by the

Norwegian Research Council through the GassMaks

program. The work in this project is focused on modeling

of chemical reactors like fixed packed bed-, bubble

column-, and fluidized bed reactors by the complete

multifluid model containing a population balance

equation for the fluid particle size distribution for the

multiphase reactors. The model equations are solved by

the modern least squares spectral element method. In

the next phase of the project the novel in-house codes

will be applied analyzing the chemical reactor processes

utilizing natural gas as feedstock.

One such activity is related to the modeling,

implementation and simulation of the Fischer-Tropsch

process operated in a slurry bubble column producing

diesel using natural gas and biomass as feedstock. For

this purpose, we are employing a combined multifluid-

population balance model for the reactive three-phase

system. The model equations are solved by the modern

least squares spectral method.

A new activity in the

group is related to the utilization of biochemical

processes that are mass transfer limited thus the bubble

size distribution is of outmost importance. Hence,

combined multifluid-population balance model is

applied for these processes as well. Further information

on this activity is outlined at:

http://www.ntnu.edu/web/ntnu-biotechnology/ntnu- bioreactor-design-and-operation .EXPERIMENTS ON FLUID PARTICLE BREAKAGE

(SUBPRO)

For the reactor group the main activity in this SFI

program is the experimental investigating of fluid

particle (i.e., bubbles and droplet) breakage (and

coalescence). A novel experimental facility is under

construction for high speed imaging of single particle

breakage events, Fig. x. The goal is to determine

parameters like the mother particle size, the number of

daughters produced in a single breakage event, the

breakage time, breakage probability, the size distribution

of the daughter particles. These are important functions

in a population balance closure model for describing the

breakage phenomena.