Department of Chemical Engineering

Annual Report 2015

28

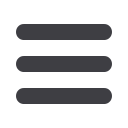

Molecular modeling results of the protonation constant,

and heat of protonation of MEA compared to

experimental results.

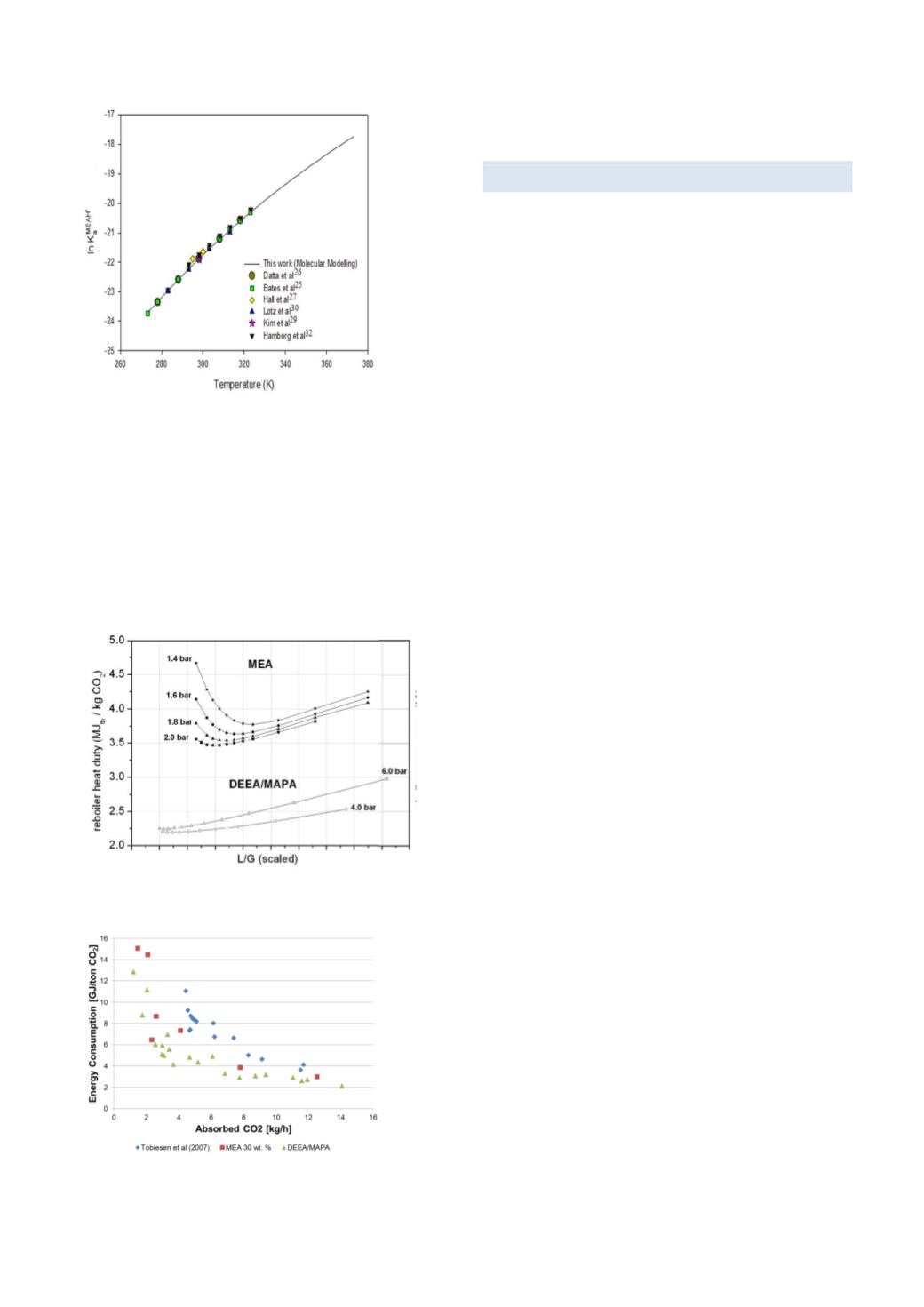

In the iCap project a new liquid/liquid solvent systemwas

simulated in CO2SIM and tested in pilot runs. In the

figure below the predicted specific reboiler duty in this

system is compared with MEA, and some results from

the pilot campaign are shown.

Results from CO2SIM.

Experimental specific reboiler duty from the lab-pilot for

DEEA/MAPA system and for 30wt% MEA.

PROCESS DESIGN

A process design is to a large extent a consequence of

developments on catalyst, choice of reaction routes,

selection of solvent system, fluid type etc. At this level of

development, the structure of the chemical system and

the kinetics are determined. Much research is focused on

these topics because even incremental improvements

may have large economic consequences. The next major

step is to find a suitable reactor and process in which to

deploy the system on a larger scale. The traditional way

of doing design of new processes is by selecting reactor

type and process configuration based on comparison to

a similar known system. Design choices are often made

on the basis of past experience or trial-and-error using

laboratory tests and repeated simulations. These

activities are necessary. However, it is not likely that the

traditional way alone will lead to the best possible

process configuration and design. Complementary tools

and methods are needed to lead the design engineer

onto the path of optimal design. Deviations from the

optimal design will lead to unnecessary loss of product

yield, unnecessary large volumes and loss of energy.

Within the conceptual process design activity some of

the most important choices are made, which have large

consequences on the profitability and environmental

loads of the final process technology. According to

Douglas (1988) the conceptual design of an integrated

plant can be broken down into a hierarchy of decisions

and organized into different levels of activities. Among

the levels of activities are reactor-separator-recycle

structures, heat integration, and separation train

sequence design. A method in focus here is a systematic

procedure based on shortcut models. A path is a line of

production on which basic operations or functions take

place. Reactants pass through a series of functions or

basic operations to form the desired products. The basic

operations are represented by design functions on the

volume path. The design functions are fluid mixing

(dispersion), distribution of extra feed points,

distribution of heat transfer area and coolant

temperature, catalyst dilution distribution and more.

The conceptual reactor design problem is solved as an

optimal control problem. Parameterization of the design

functions and the state variables are applied. The

realization is a staged process string of multifunctional

units.