Department of Chemical Engineering

Annual Report 2015

26

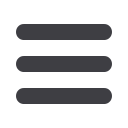

Fig. X Experimental facility for single particle breakage

investigations.

ACID GAS REMOVAL BY ABSORPTION

Removal of acid gases, like CO

2

and H

2

S using chemical

absorbents is a commercial technology used for decades.

However novel, environmentally friendly solvents with

low energy requirement during solvent regeneration are

needed. Our work is concentrated along two axes, one

studying CO

2

capture from off gases from fossil fuel

power plants as well as from the iron and steel-making

industry, and the other directed toward the removal of

acid gases from natural gas.

We have experience with theoretical screening by use of

computational chemistry, experimental screening and

solvent development, characterization of equilibria,

thermal properties, transport properties and kinetics

and testing in a laboratory pilot plant. In parallel we

develop rigorous thermodynamic models and improved

models for combined mass and heat transfer. In addition,

we have developed together with CO

2

Capture Process

Technology group at SINTEF MK a full rate based

simulator for the whole absorption/desorption process,

CO2SIM. Surplus to these activities, we have been

working on solvent degradation and corrosion as well as

environmental issues.

We have many research projects in this area funded by

the Research Council of Norway, the industry, and the

European Union. Our work is concentrated along two

axes, one studying CO

2

capture from off gases from fossil

fueled power plants and industry, and the other directed

toward the removal of acid gases from natural gas. We

were heavily involved in EU FP6 projects, e.g CASTOR and

CAPRICE. This work continued in the EU FP7 CESAR and

as coordinator of the EU FP7 iCap project. Currently we

are partner in the OCTAVIUS and HiPerCap projects. Of

the current national projects on CO

2

capture, the largest

is

SOLVit

, a JIP with Aker Solutions and SUBPRO.

Furthermore, we leading national project

3

rd

Generation

membrane contactors

(3GMC), and are partner in

following two national projects:

Low energy penalty

solvents

(LEPS) and

Magnetic separation of CO

2

through

sorption on magnetic hybrid nanoparticles

(CARBOMAG).

COMBINED SUBSEA HYDRATE CONTROL AND H

2

S

REMOVAL (SUBPRO)

Pipelines used to transport produced gas have quality

restrictions related to content of water, CO

2

, H

2

S and

heavy hydrocarbons. If these requirements cannot be

met, oil wells may need to be closed. Today on a typical

platform water is removed by Triethylene glycol and

amine processes are used to remove CO

2

and H

2

S. In

addition to this Monoethylene glycol is used for hydrate

control in the well flowlines, giving in total 3 different

chemical systems with separate absorption and

regeneration equipment. Simplifying the chemical

systems or moving equipment and process elements

subsea could be a way to ensure better energy efficiency

and utilization of the resources.

We are working on developing a new regenerative

process where both hydrate formation is controlled and

H

2

S removed. Since this would be a regenerative process

significantly higher concentrations of H

2

S could be

treated than normally is the case with scavengers.

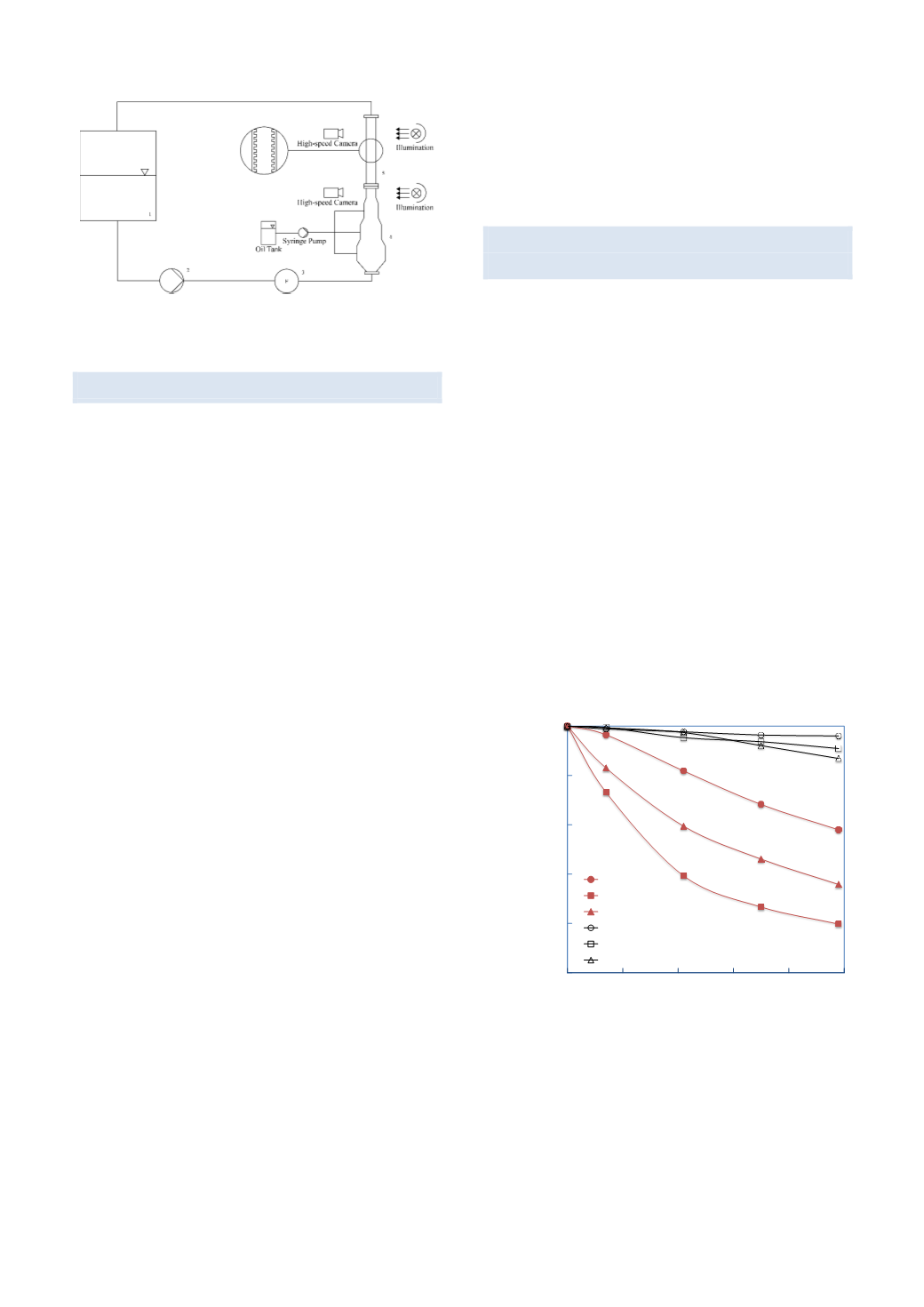

Amine concentration as a function of time during thermal

degradation experiments.

0%

20%

40%

60%

80%

100%

0

10

20

30

40

50

Amine conc (remaining)

Days

MEA+H2O

MEA+MEG

MEA+TEG

MDEA+H2O

MDEA+MEG

MDEA+TEG