Department of Chemical Engineering

Annual Report 2015

34

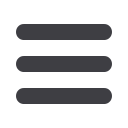

Figure: A paper surface with ground calcium carbonate

that has been partly agglomerated by nanocellulose.

(Photo: V. Ottesen, NTNU)

A main focus is to establish new research projects.

Currently we work in several research projects funded

from the Nano 2021 program of NFR, Petromax 2. In

2013 the NORCEL project was started with Kristin

Syverud (PFI/NTNU) as project manager. The project

aims at developing tailored nanocellulose materials for

application in medicine, papermaking and oil production.

Vegar Ottesen and Silje N. Molnes (UiS) are PhD fellows

in this project.

During 2014 one new research project, NanoMBE was

established together with Liyuan Deng from the

Environment and reactor group at IKP as project

manager and PFI as the third project partner. The project

has three PhD students and aims at developing improved

polymer-nanocomposite membranes for gas separation.

Jonathan Torstensen is a PhD fellow in this project.

During 2015 the project “Green high performance

systems for Enhanced Oil Recovery” was started. The

project is led by PFI. Reidun Cecilie Grønfur Aadland work

with nanocellulose in enhanced oil recovery (EOR)

The related project “Development of high-performance

viscosifiers and texture ingredients for industrial

applications based on Cellulose Nanofibrils (CNF)” was

also started in 2015.Ragnhild Aaen is a PhD-student in

this project, working on rheological properties of

cellulose nanofibrils

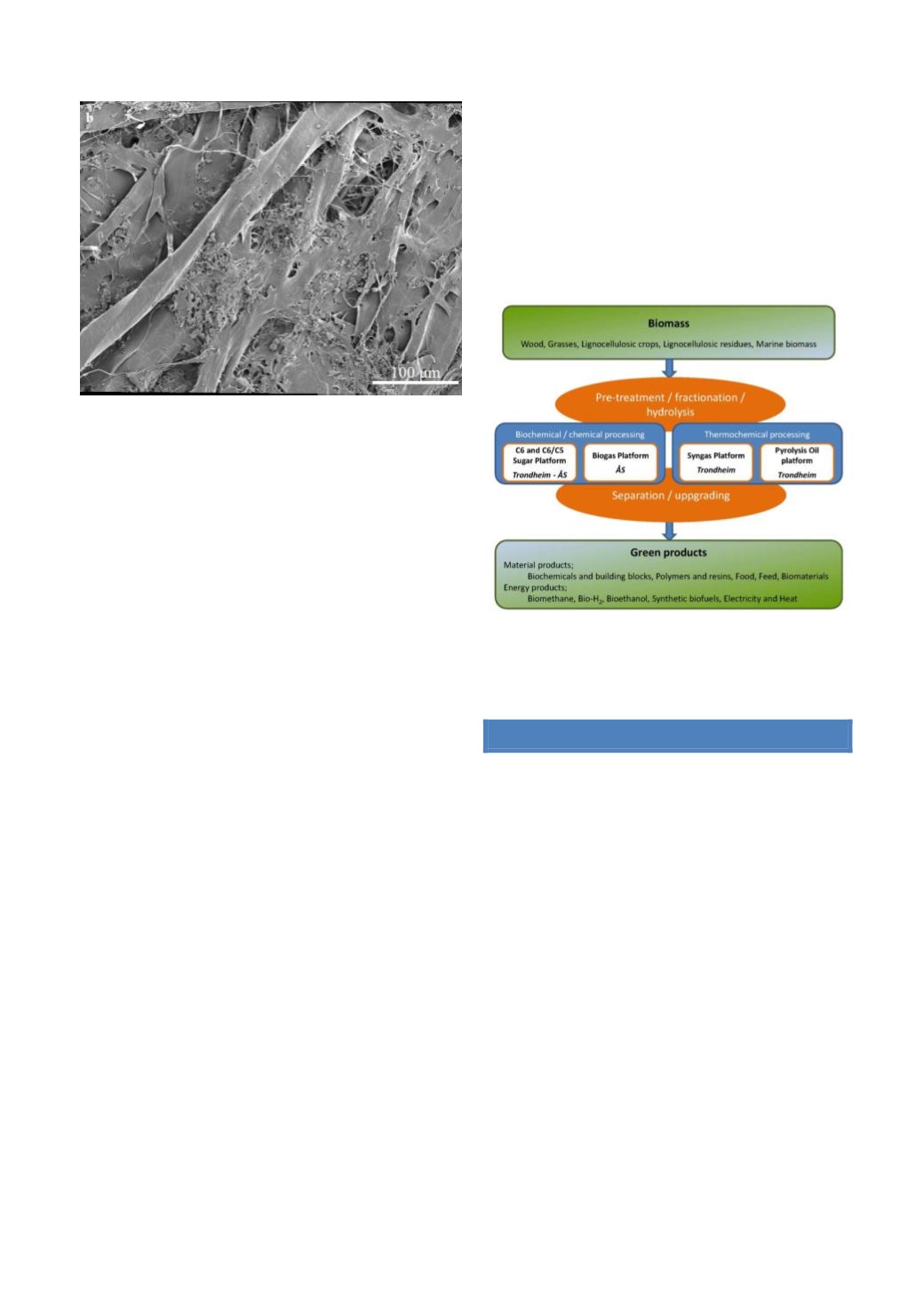

We are also a partner in the Norwegian biorefinery

laboratory

project

(NorBioLab:

http://www.pfi.no/Biorefinery/Biorefinery-Projects/NorBioLab/) which is a national laboratory for

biorefining. This involves the development of processes

for sustainable conversion of Norwegian land and sea-

based biomass into new, environmentally friendly

biochemicals, biomaterials and bioenergy products. This

infrastructure gives us new research possibilities for

converting lignocellulose to chemicals, materials and

fuel.

Figure: The equipment in the NorBioLab project covers all

the most relevant conversion routs from biomass go

green products.

TRENDS

During the last 10 years the focus of our research has

shifted from exclusively pulp and paper to including

research on bio-fuel, nanocellulose and bio-composite

materials. Cellulose based particles in film and composite

materials can give better oxygen barrier and mechanical

properties to the materials. An overall goal in this

research is replacing non-renewable packaging materials

(plastics, aluminium foil) with cellulose based

(renewable) materials. The research and application

areas for nanocellulose have been much extended. The

group is active in research on production, modification,

application as filter material, barrier material, wound

dressing, membrane materials and additive for oil

production.

Biofuel manufacturing processes are regarded as a first

stage in the development of biorefinery processes for

the manufacture of energy, chemicals and materials

from renewable resources. Together with PFI we are

conducting research on the use of wood and agricultural