Department of Chemical Engineering

Annual Report 2015

30

phase of execution is to design and construct large

modules for a two-stage FSC-membrane system, and to

prove the performance as expected from process

simulation and additionally to document the membrane

durability by exposed to the flue gas of Brevik cement kilns

over 24 months.

BIP GASSMAKS/ NFR PROJECT NAGAMA

The project started late 2011 ended in 2015. The

objective has been CO

2

removal from high pressure

natural gas streams using a polymeric blend membrane;

using as one of the polymers in the blend the patented

PVAm facilitated transport membrane – other materials

suitable for high pressure applications are also

considered. The project includes material development,

pilot construction, durability tests and simulations. The

main challenge in this project is to maintain the good

performance at high pressures (

100 bar). Advanced

high pressure test rigs have been built, one for

permeation tests and one for durability tests. Special

restrictions for HMS are very important in this operating

range. Industrial partners are Statoil and Petrobras.

Bundle of hollow fibre membranes in an industrial

module–packing densities can be up to 30 000 m2/m3

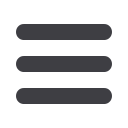

Illustration of the mechanism in the patented CO2

facilitated transport membrane

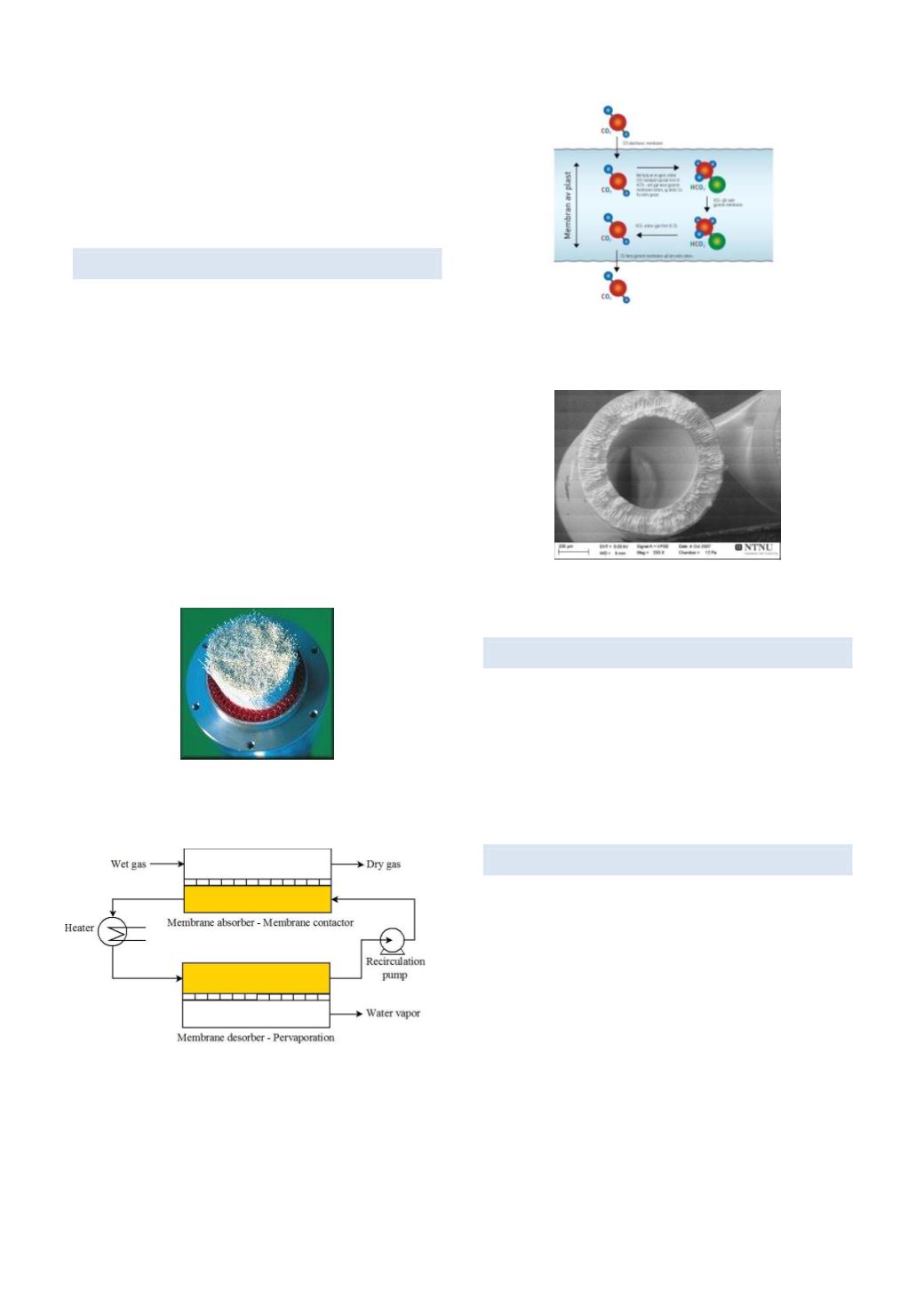

SEM-picture showing a membrane. D0-DI: 1-6 mm cut

though a hollow fibre

KMB PETROMAKS / NFR A GREEN SEA

The project started in 2010, and Sintef Energy is the

coordinator and ended in 2015. The project has had

activities within four alternative technologies for natural

gas sweetening. Memfo’s activity within the project has

been to development of a nanocomposite membrane

material for a membrane contactor There were two PhD-

students in the project, one within Memfo.

MCIL-CO

2

/ NFR /CLIMIT

The project started in the middle of 2012 with focus on

the development of a novel membrane contactor

process using ionic liquids as absorbents for pre-

combustion CO

2

capture. The project is scheduled for 4

years and finances 2 PhD-students within Memfo. The

research activities include (1) build up a lab scale setup

and simulation modules to demonstrate the proposed

process and (2) provide knowledge and experimental

data for the further up-scaling of the process. In 2013

two exchange PhD students from the project partner also

contribute to this project in the development of ionic

liquid based solvent.