Department of Chemical Engineering

Annual Report 2015

24

Chemical Reactor Research

Acid gas removal with absorption

Crystallization and particle design

Membrane research

Process designProject and MSc student can be involved in all areas of

our work.

CHEMICAL REACTOR RESEARCH

The activity on reactor engineering has been

concentrated in fields directly supporting the design and

development of chemical reactors and reactive

separations. The most important research areas are:

Mathematical modeling of chemical reactors.

Multiphase flow modeling.

Design of novel solution methods and algorithms.

Experimental analyses of fluid flow, fluid particle

coalescence and breakage, CO

2

sorption by

adsorbents and heat- and mass transfer in chemical

reactors.

Experimental validation of numerical models.

Analysis and design of reactors for environmentally

friendly chemical processes.

The research in these fields comprises both experimental

and theoretical studies, but emphasis is placed on

modeling, development of numerical methods and in-

house software for multi-phase reactor simulations.

The simplest models considered are normally

implemented in the programming language Matlab,

whereas the computationally demanding models are

implemented in FORTRAN 90 and C++. Application areas

are special chemicals reactors, polymer production,

sorption enhanced steam methane reforming,

conventional synthesis gas and methanol synthesis,

membrane reactors, wood gasification and chemical

looping combustion.

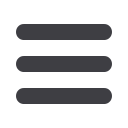

A circulating fluidized bed reactor used for studies of

sorption enhanced steam methane reforming (SE-SMR).

Educationally the main objective of our group is to

educate MSc for the Norwegian industry and to raise the

national scientific competence in our field of research

through PhD studies.

RESEARCH ACTIVITIES

The most important research projects are described in

the following paragraphs. For a more comprehensive

description, see:

(www.ntnu.no/kjempros/miljoreaktor)

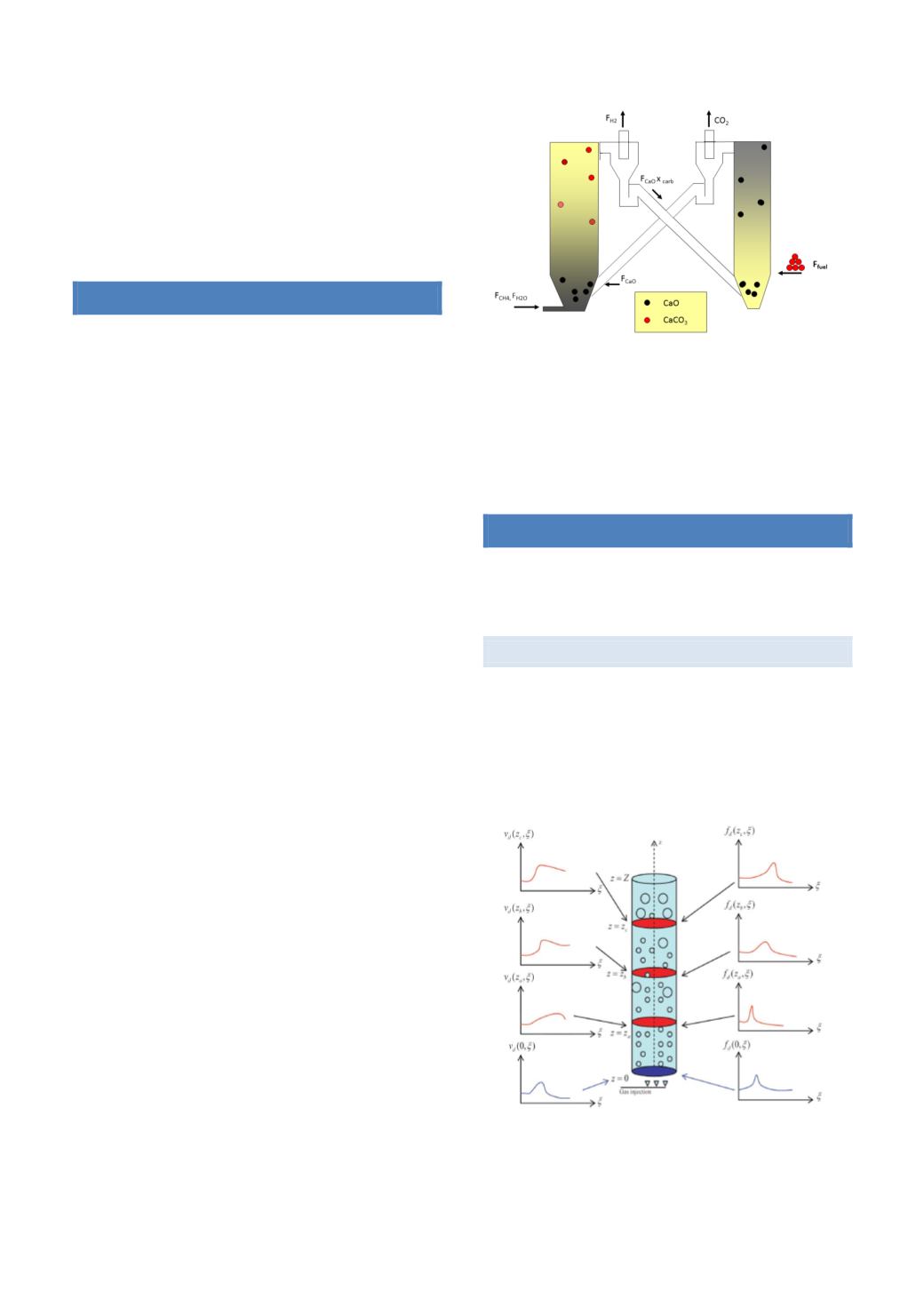

MODELING OF MULTI-PHASE REACTORS

We have for more than 20 years been developing in-

house CFD codes for simulating multiphase flows in

chemical reactors. Lately, our main focus has been put

on developing modules for bubble/droplet break-up and

coalescence within the population balance equation

(PBE) framework.

A cold flow bubble column used for studies of bubble

breakage and coalescence mechanisms.