120

steel connectIons

the connections between the different wood

components are all made out of steel, which is mainly

hidden in the wood. caused by the special shapes

and requirements, all the connections had to be

customized for the project, that’s why we made them

on our own.

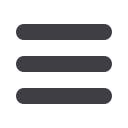

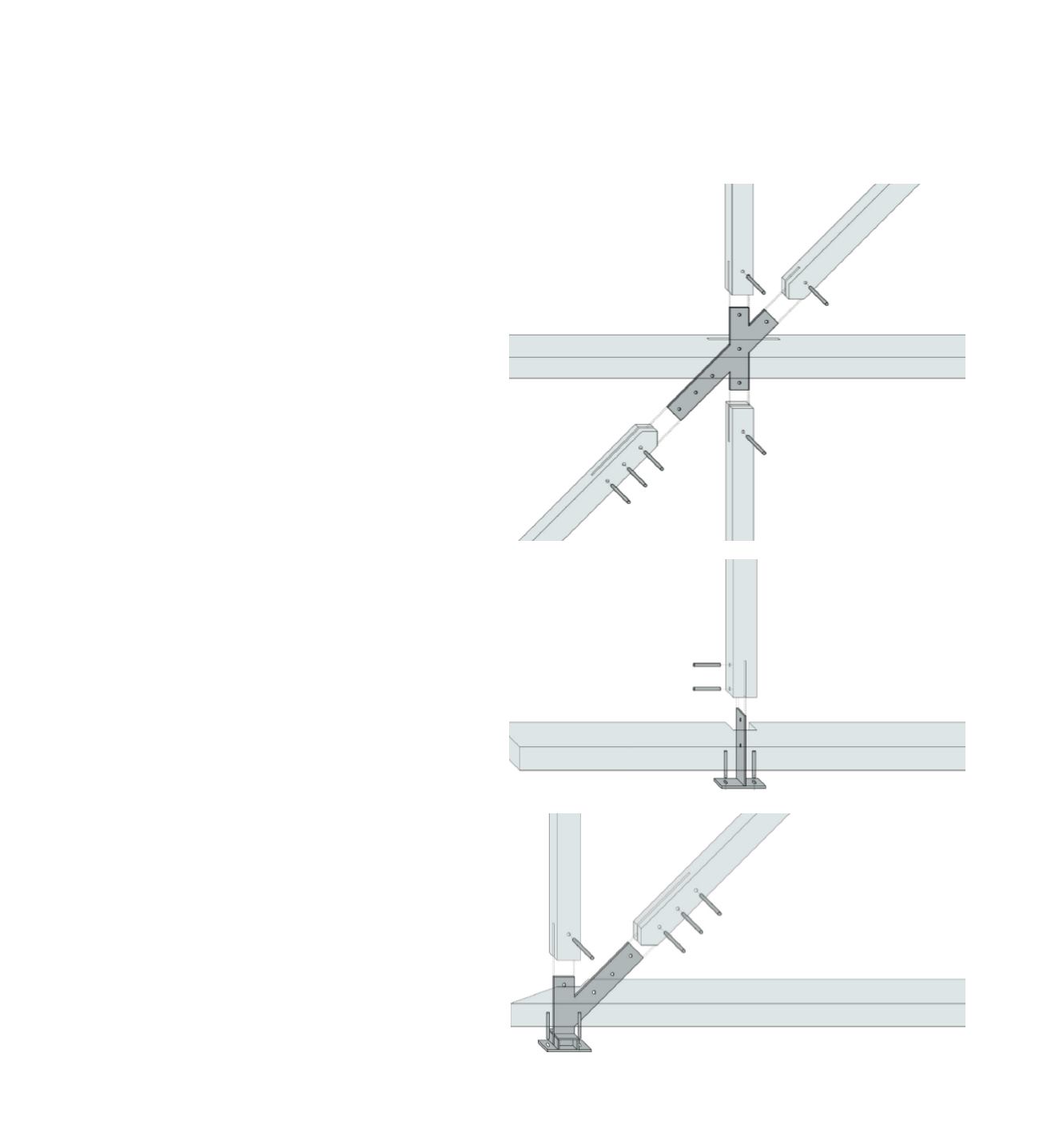

the main structure such as the core demanded three

different steel shapes: footings for the four corners,

footings for the middle columns and the core columns

with different angles, a cross for the connections

between the diagonal bracing and plaids for the

corners. the plaids are located where the beams are

touching on the corners and have the purpose to hold

them toghether and take horizontal loads.

after grinding, sawing, welding and drilling the

steel plaids, they had to be galvanized to make them

resistent against corrosion.

the over all system for the connections is a slot in the

wood in which the steel can be put in and fixed with

fitted bolts, so that you can only see the bolt from the

outside. the bolts have a diameter of 12mm and the

amount is depending on the horizontal load/ wind

loads, so has the middle cross more then the footings.

to fix the footings to the concrete slap, we drilled

holes, filled them with special glue and put a bolt in.

these had to dry for some hours to be as stabil as we

need it.

to give the wood the possibility to move, the holes

in the steel plaids connecting the structure to the

concrete are oval. this feature is preventing the

wood from cracking and belongs to the category

„constructive wood protection“, such as the 50mm gap

between the slap and the construction. due to that the

wood is protected from upcoming moisture.

mIddle cross connectIon

mIddle loWer column connectIon

corner connectIon