80

DETAILS

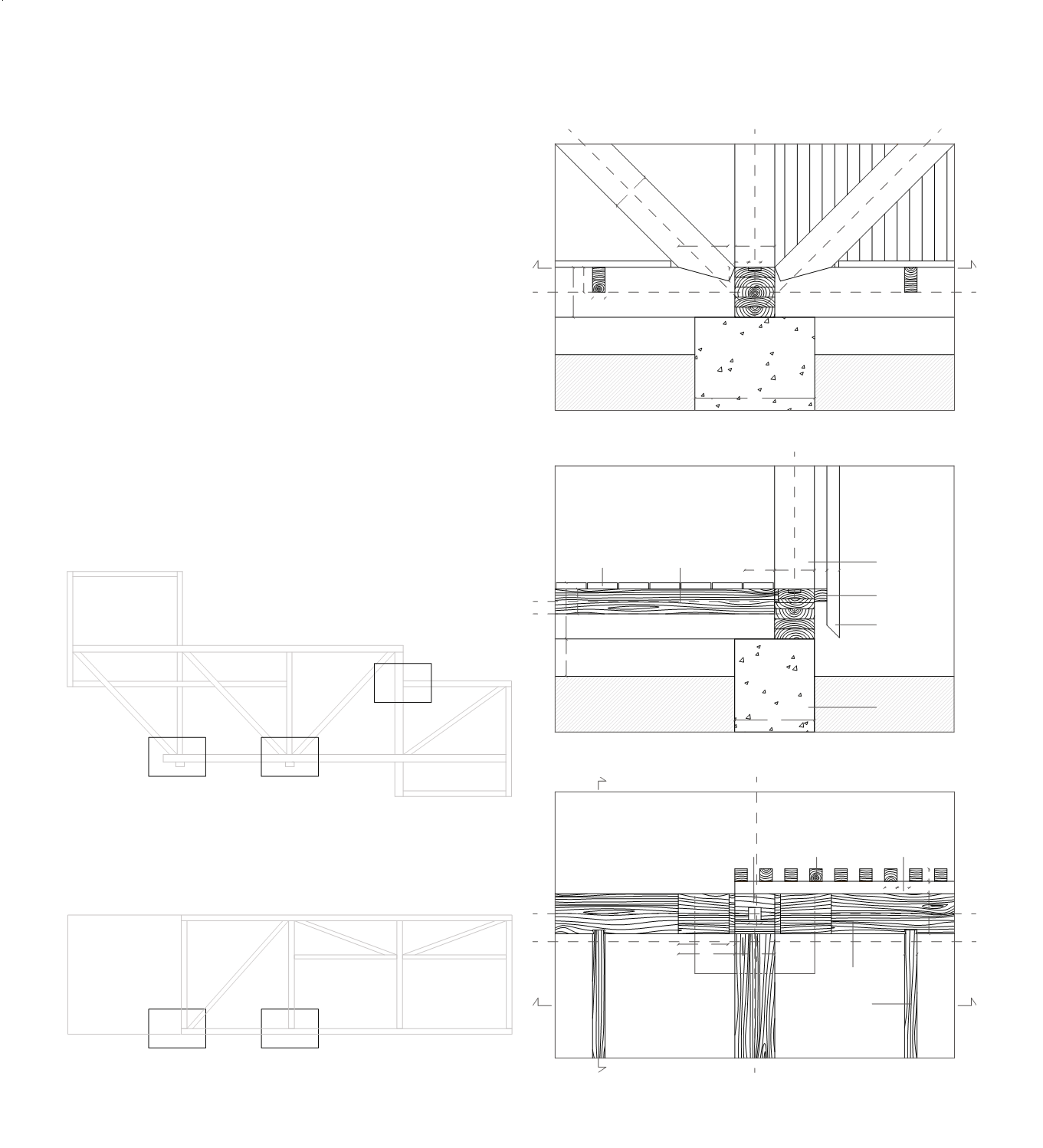

We worked with three of the more important and complicated

wooden joints, in order to find out if the structure we calculated

could be built. Therefore, after calculating the compression

and tension of the joints, we drew two details, always aware

of the fibre directions in the wood pieces. Later we built the

two wood joints in scale 1:2, and one of them in 1:1 in glued

laminated wood (glulam). We concluded that if this structure

was to be built we had to: either enlarge the dimensions of the

beams and columns, meaning a more expensive construction;

or use steel in the joints instead of the pure wooden joints. This

would allow the structure to be lighter and slimmer. Another

solution is to increase the number of trusses, decreasing the

compression and tension, but this will change the appearance

of the structure.

Despite discovering this problem, our group decided to continue

to work with wooden joints and to try to find the best possible

details for this structure to work.

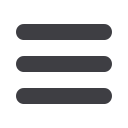

DETAIL 1

Detail 1A, Section B-B

1

Detail 1B, Section C-C

1

Detail 1C, Plan P-P

1

B

Selected details in plan

Selected details in section

2

2

1

1

3

160

200

100

480

55

203

160

55 50

23

48.5

320

50

200

100

160

50

120

150

25

226

160

50

50

203

160

50 50

50

50

23

B

1

C

1

C

P

floor board

120x25mm

glulam timber floor beam

100x50mm

glulam timber column

160x160mm

glulam timber column

160x160mm

cladding support

structure

50x50cm

glulam timber

floor beam

100x50cm

glulam timber beam

200x160cm

cladding support structure

50x50cm

wooden cladding

50x50cm

wooden cladding

50x50cm

concrete foundation

320x480mm

P

1