Table 4:

SiStruc analysis performed on the untreated and the treated sample

Phase

%wt. untreated

%wt. annealed

Relative

variation

FeSi

2

0.458 (47%)

0.361 (48%)

-21%

Al

6

CaFe

4

Si

8

0.190 (20%)

0.104 (14%)

-45%

CaAl

2

Si

2

0.184 (19%)

0.118 (16%)

-36%

TiFeSi

2

0.093 (10%)

0.067 (9%)

-28%

Al

8

Fe

5

Si

7

0.023 (2%)

0.075 (10%)

+226%

TiSi

2

0.009 (1%)

0.009 (1%)

0%

Al

3

FeSi

2

0.009 (1%)

0.015 (2%)

+67%

TOTAL

0.966 (100%)

0.749 (100%)

-22%

The total quantity of intermetallics decreases after the annealing. FeSi

2

is the most

expected compound in both samples. The quaternary phase and CaAl

2

Si

2

follow, but

in the annealed sample their quantities decrease. TiFeSi

2

is present in the same

relative mass fraction for each sample. Al

8

Fe

5

Si

7

is expected to increase after the

annealing with respect to other phases. TiSi

2

and Al

3

FeSi

2

might be found in low

amounts.

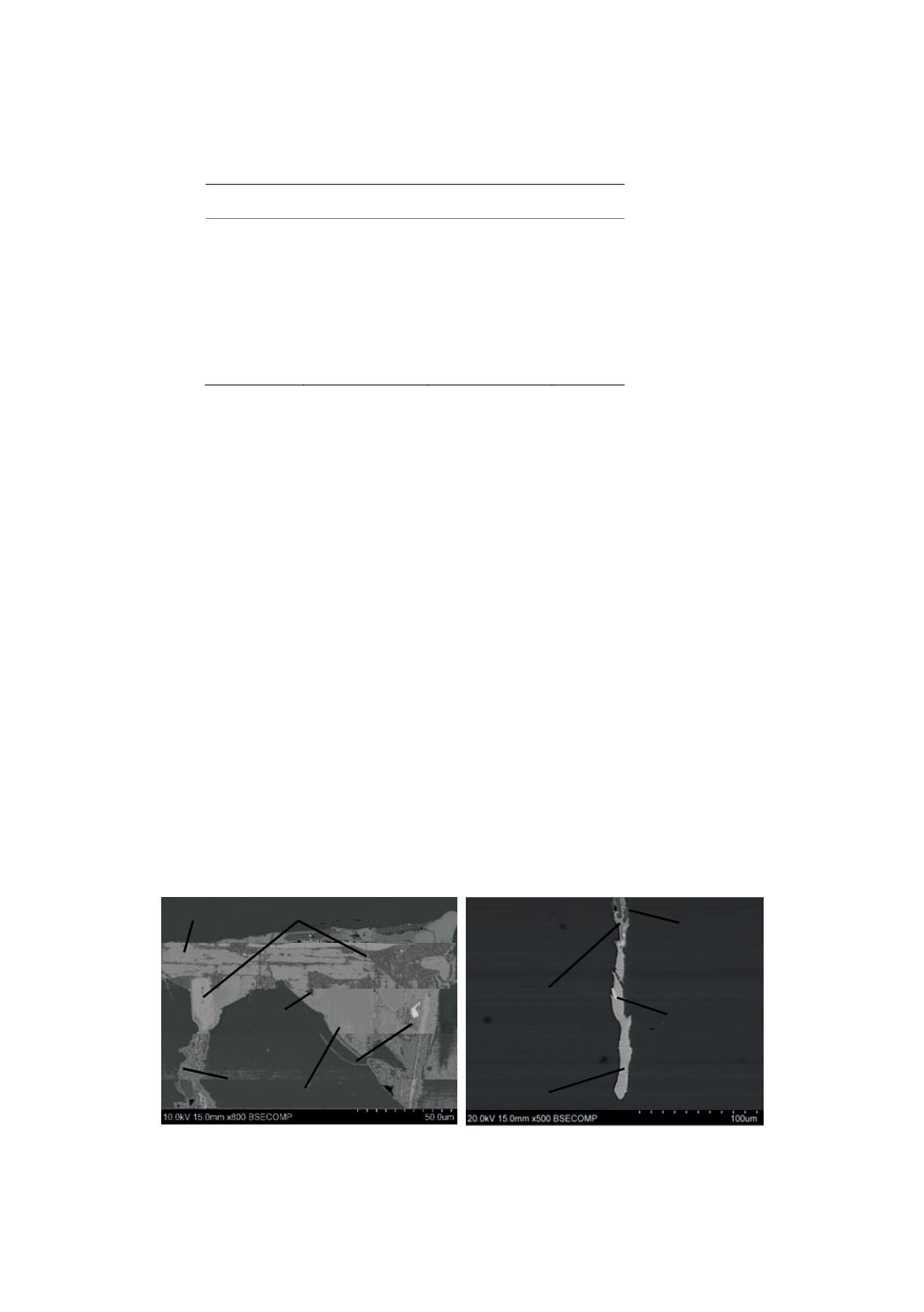

3.2 EPMA and BSE-SEM analysis

3.2.1 Untreated and treated sample at 600°C

Figure 4 show two complex intermetallic particles from the untreated sample and the

sample treated at 600°C. These two samples have been compared in the same

paragraph since the microstructure was very similar. The particles come from the

solidification fronts meeting point. This position in the cast lies in slightly below the

centre of the thin cast. The material solidifies last in this section. All the phases

predicted by SiStruc

®

can be seen in the two figures. FeSi

2

is both present at its high

temperature (HT) and low temperature (LT) structure. They could be recognised from

their stoichiometry, as well as by the presence of cracks and Si precipitates in the LT-

FeSi

2

. Al

6

CaFe

4

Si

8

and Al

8

Fe

5

Si

7

do not show peculiar shapes and are detected all

over the sample. CaAl

2

Si

2

is mostly present in the centre of the cast, especially at the

edges of elongated intermetallics. TiFeSi

2

comes either as large particles at the

borders of the intermetallics, or as rectangular precipitates in the intermetallics' cores.

Eventual cracks formed go through FeSi

2

without crossing TiFeSi

2

particles in the

majority of the cases. Other dissolved elements form compounds in minor quantity.

Figure 4

: Two particles coming respectively from the solidification fronts meeting point of the

untreated sample (a) and from the bottom of the treated sample at 600°C (b)

FeSi

2

CaAl

2

Si

2

TiFeSi

2

Si precipitate

Al

9

Fe

5

Si

8

Al

6

CaFe

4

Si

8

CaAl

2

Si

2

Al

6

CaFe

4

Si

8

TiFeSi

2

FeSi

2

88