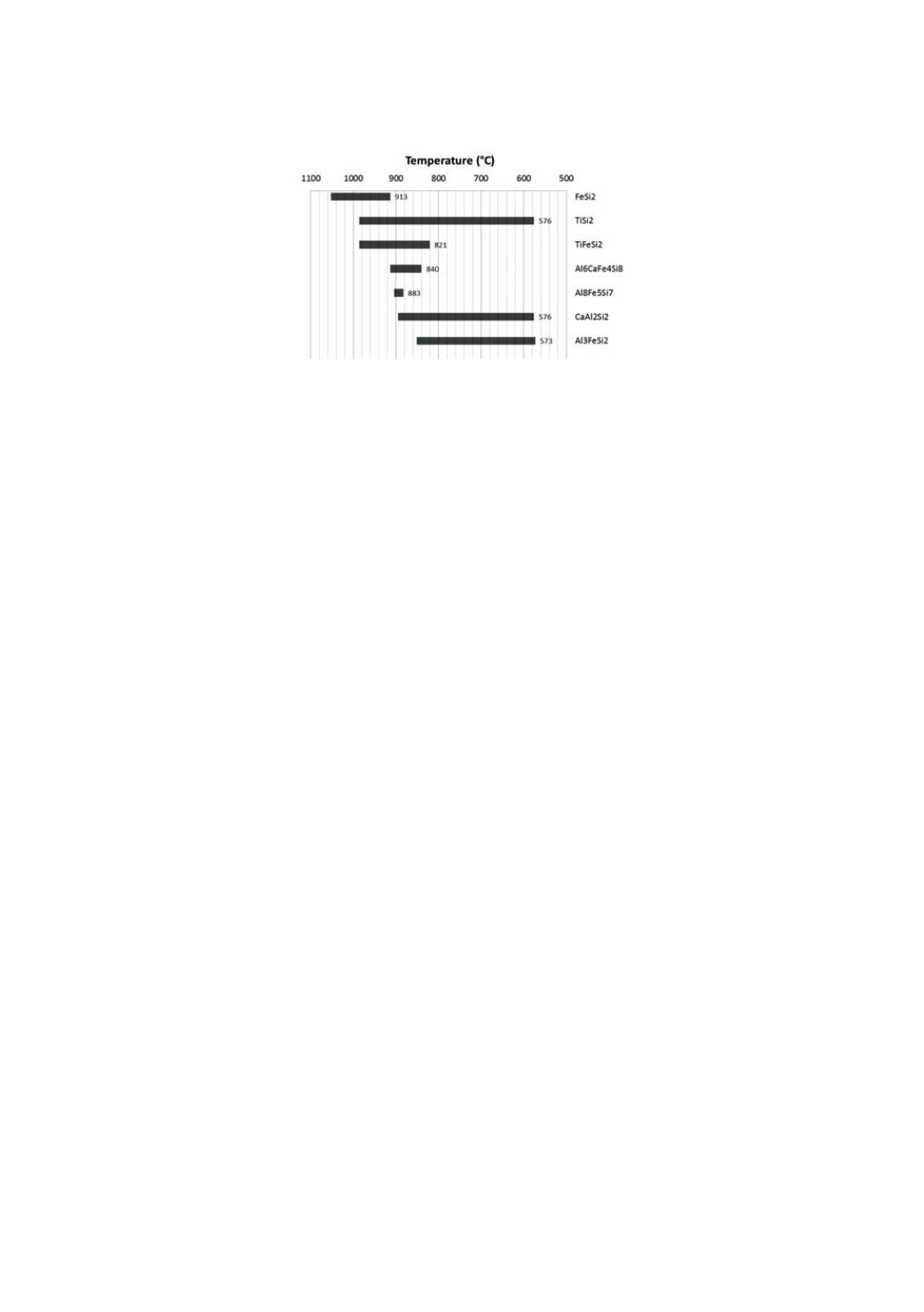

Figure 6

: Cooling ranges of intermetallic phases calculated by SiStruc

®

. The temperatures

delimiting the melting range are written on the side of each bar

It is not true that the longer the melting range, the more phase will be present. The

amount of some elements in the material will be the determining factor. Ca and Ti are

present in a lower extent compared to Fe and Al. Ca is limiting the quantity of Ca-

containing phases, and Ti does the same for the TiFeSi

2

phase.

4.2 Refining and segregation effects in the annealed sample

Changes in composition were expected in the annealed sample. Silicon was molten in

air. A white layer was noticed on the top of the cast, once the sample was extracted

from the furnace. This layer is generated by the oxidation of the material during the

melting step. Elements diffused to a slag phase from MG-Si. The slag will contain

mainly Si, Al and Ca oxides. All these elements have negative

ǻ

G° at 1450°C [20],

which is the highest temperature reached during the treatment. Ca also starts to

evaporate at temperatures slightly above 1450°C. This transformation could have

happened as well, thus further reducing the content of calcium.

Minor oxidation effects could have altered the quantity of Fe and Ti. However,

their

ǻ

G for the oxidation reaction is less negative than silicon. Once Si becomes

solid, elements are not able to diffuse rapidly to the slag, hence the lower distribution

coefficients for Ti and Fe compared to Al and Ca [21]. The segregation effect

becomes the most plausible hypothesis for Fe and Ti decrease and displacement in the

sample (Figure 7). The material for the chemical analysis was taken from the sides of

the cast and not from the center. The segregation is controlled by the heat exchange

coming from the lateral sides of the mold, as well as from vertical solidification. A

solidification front is developing from the bottom with a slower velocity compared to

the solidification velocity from the sides and from the top. This can be said since the

sample was standing on a warm surface. The temperature gradient developed from the

bottom was therefore small.

ϭϬϱϮ

ϵϴϲ

ϵϴϲ

ϵϭϯ

ϵϬϰ

ϴϵϱ

ϴϱϭ

90