Batteries

One of the major focuses of Li-ion batteries over the last two decades has been in the

development and discovery of novel anode architectures with enhanced properties such

as increased capacity, cycle life and rate performance, together with consideration of

production cost and environmental impact. Silicon has been considered the best choice

for a number of important theoretical considerations.

Firstly, silicon forms a stable alloy with lithium of up to 4.4

ܮ

݅

ା

per formula unit Si,

leading to a vast theoretical capacity of 4212

݉

ܣ

ή ݄ ή ݃

ିଵ

, which is considerably higher

than that of graphite (372

݉

ܣ

ή ݄ ή ݃

ିଵ

). Secondly, Si anodes display long voltage

plateaus at approximately 370 mV vs Li/

ܮ

݅

ା

, thereby providing stable operating voltages

when coupled with positive electrodes such as LiCoO

. Lastly, Si is the second most

abundant element in the Earth's crust and is thus considered a candidate for reasons of

viable production cost and availability. However, silicon has a drawback that it is fact

that Si suffers from a large volume change (±400%) during (de)alloying process, the

strain of which potentially leads to pulverization of the local structure.

In order to avoid the latter problem, one approach mixes small quantities of silicon

particles in a flexible polymer binder, adding carbon to the mix to conduct electricity.

Tesla, for example, is increasing the capacity of his car batteries by adding little by little

increasing amounts of silicon in the anode. They have set the goal of increasing the

capacity of its batteries by 5% per year (although not all this increases will solely due to

adding more silicon).

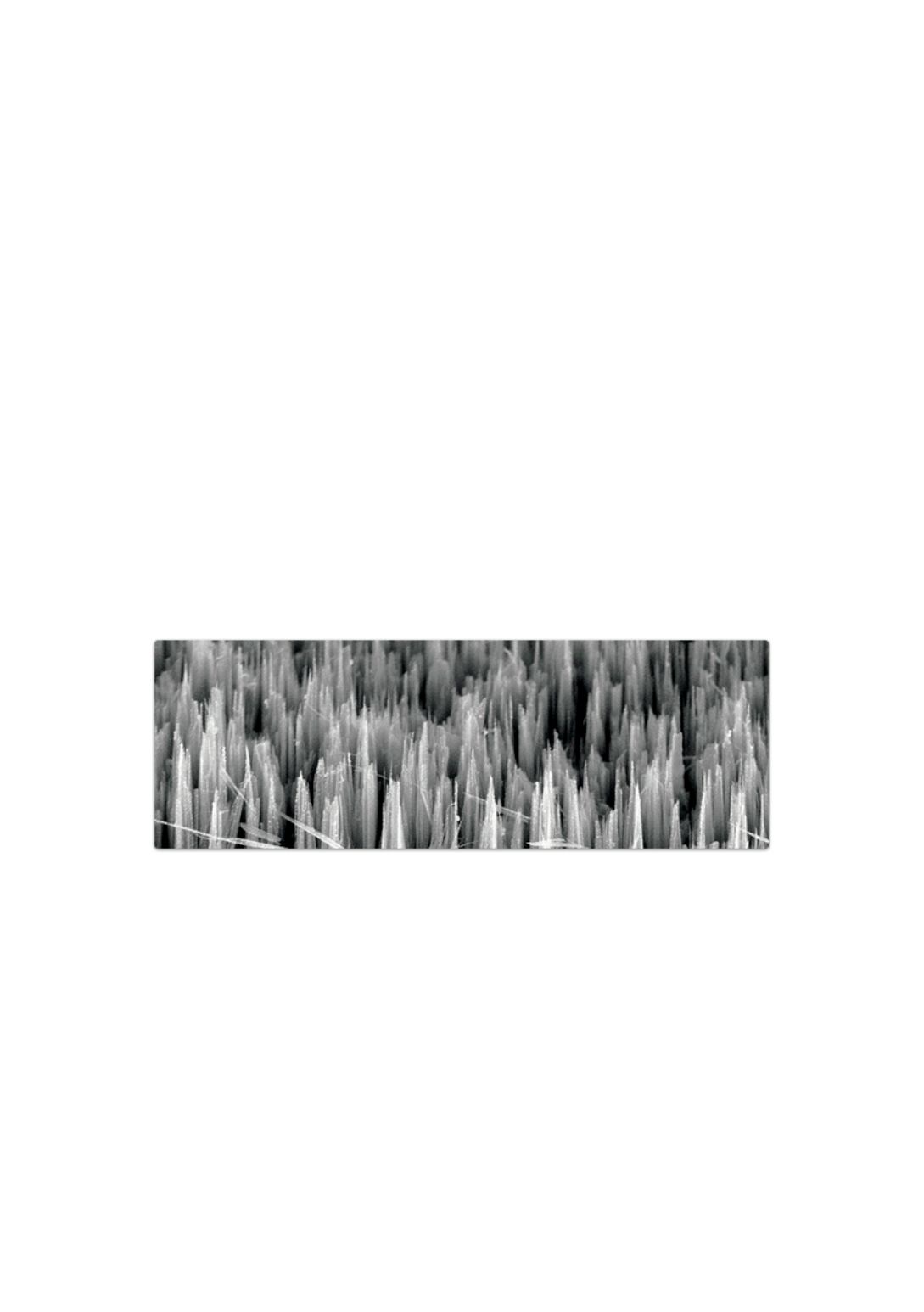

&ŝŐƵƌĞ ϭ

͘

WŝůůĂƌĞĚ ƐŝůŝĐŽŶ ƉĂƌƚŝĐůĞ ƉƌŽĚƵĐĞ ďLJ ĂƐƐŝƐƚĞĚ ĞƚĐŚŝŶŐ

A novel approach by Nexeon has been to form nanoscale Si pillar arrays on micron scale

(2-25 microns) by metal assisted etching (Fig. 1), the resulting structure is treated with

binder and additives to form a composite electrode.

Independently of the approach, it is required micronized silicon with a purity between

99,99% to 99,999%.

18