Experimental procedure

Experiments will consist in producing reactive mass at lab scale and studying the

transfer of catalyst from the reactive mass to fresh silicon.

The indicators for the study will be the amount of copper on added fresh silicon after

the transfer and the productivity of fresh silicon activated by copper transport.

The parameters studied will be the experimental conditions during the transfer step:

temperature and addition of tin, zinc and aluminium.

Lab reactor :

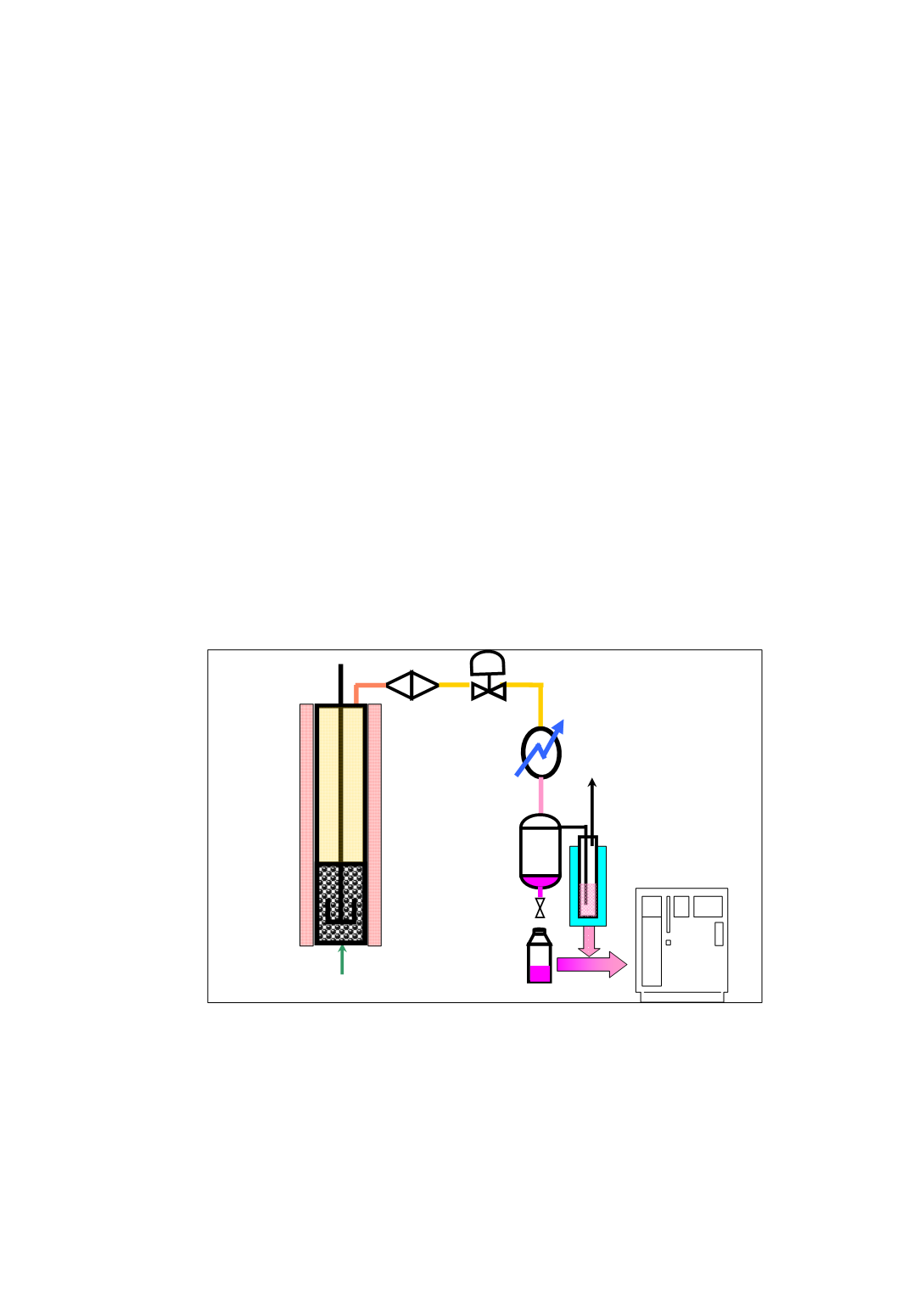

Experiments are carried out in a glass stirred bed reactor of a capacity of 0.8 liters.

The schematic drawing of the experimental set- up is shown in Figure 4.

The reactor is heated by an electric oven coupled with a regulating system PID. The

temperature setting is fixed between 250 and 300°C. Methyl chloride (MeCl) is

continuously distributed through a porous plate at a mass flow rate of 60g/h.

Methylchlorosilanes (MCS) are condensed, at the column outlet, by a water cooler.

Unreacted methyl chloride is trapped in an acetone and dry ice mix.

Figure 4

: Scheme of experimental set-up of MCS synthesis in laboratory stirred bed.

CPG

MeCl = 60 g/h

Contact Mass 210g

Si – Cu - Zn - Sn

T = 250-300°C

100-300rpm

Noncondensables (CH

4

,C

2

H

6

…)

MCS

129