(Me

2

SiCl

2

) is the main product of the reaction but it is produced together with many

by-products.

...

,

,

,

,

2

2

3

3

2

2

, ,

)(

HSiCl

Me

MeHSiCl

SiCl

Me

MeSiCl

SiCl

Me

MCS

g

highboilin

lowboiling

MCS

MeCl

Si

g

g

g

Sn Zn Cu

g

s

Industrially, this heterogeneous and highly exothermic reaction (

Hr = -284.1 KJ/mol

if we take only Me

2

SiCl

2

into account), takes place in a fluidized bed reactor (FBR)

under a pressure of between 2.5 and 4 bars and a temperature around 300°C. Common

objective of the MCS producers is to perform the reaction with a high level of

productivity, a high selectivity of Me

2

SiCl

2

and good silicon utilization.

Despite numerous studies and publications, today the mechanism of the direct

synthesis of MCS has not been fully understood. Particularly for this reaction, is that

the catalyst and promoters are supported on silicon, which is a reactant [4].

The performances of the reaction will depend on the initiation step (active sites

formation though reaction between silicon and copper), on the evolution of the

contact mass (silicon surface is constantly changing due to silicon consumption by the

reaction) and on the ability of the system to regenerate. Copper transport from

activated particles to fresh silicon is key to maintain stable performances.

Bibliographic review

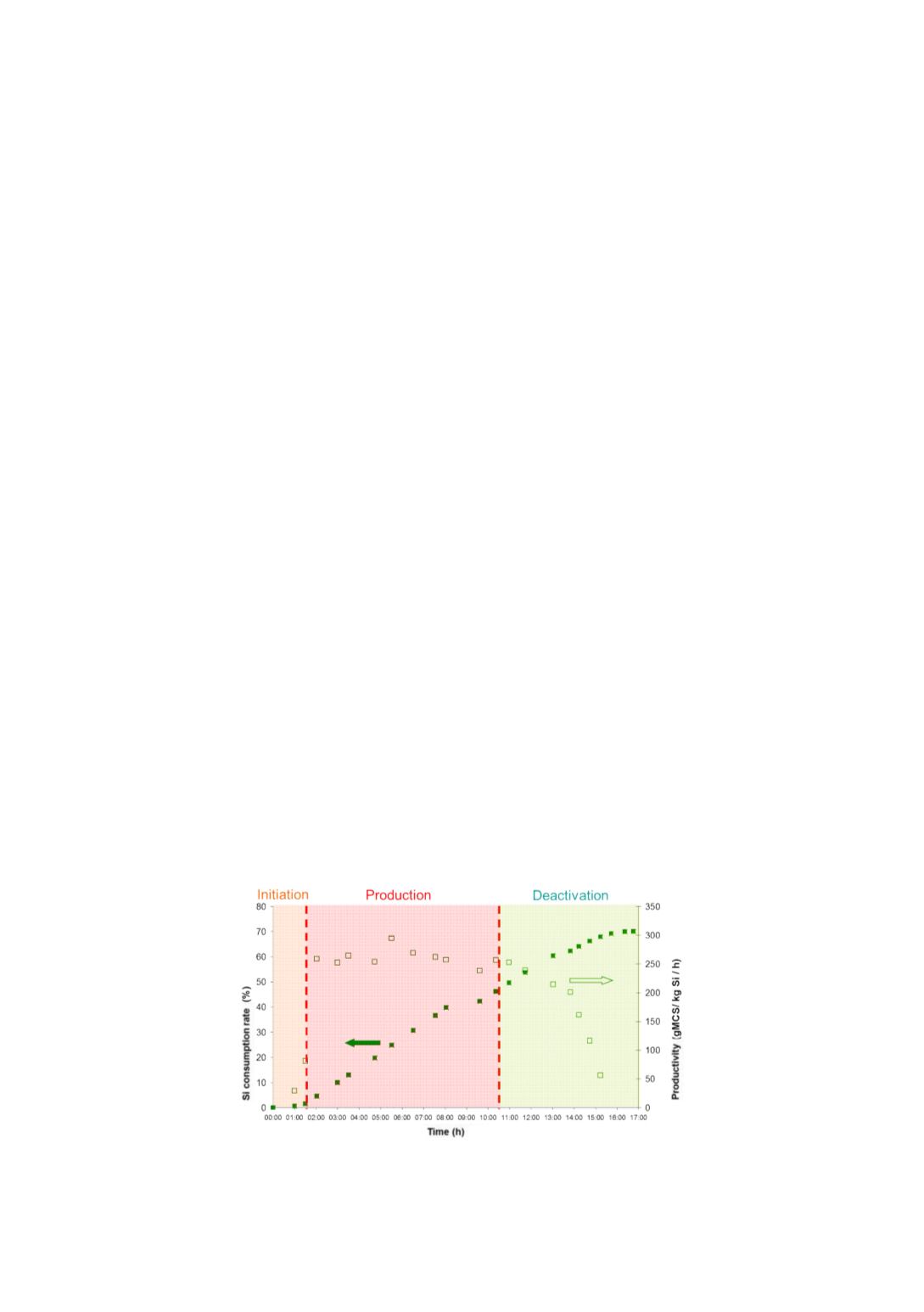

In a batch mode, performances of the direct synthesis will depend on the initiation

step. This step has been extensively studied at lab scale since the fifties [5-8]. In this

step, chemistry and hydrodynamics are strongly interlinked. Main drivers for the

initial performances are silicon chemical quality and particle size distribution

(PSD),

catalysts and cocatalysts chemical quality and PSD, pressure, temperature, quality of

the mixing. At the end of the initiation, stable performances in term of productivity

and selectivity are obtained in the reactor.

In batch mode, deactivation of the mass can be observed at lab scale: after

consumption of a part of the silicon, the performances start decreasing as represented

in the graph below.

Figure 1

: Silicon conversion and productivity evolution in MCS batch reaction

126