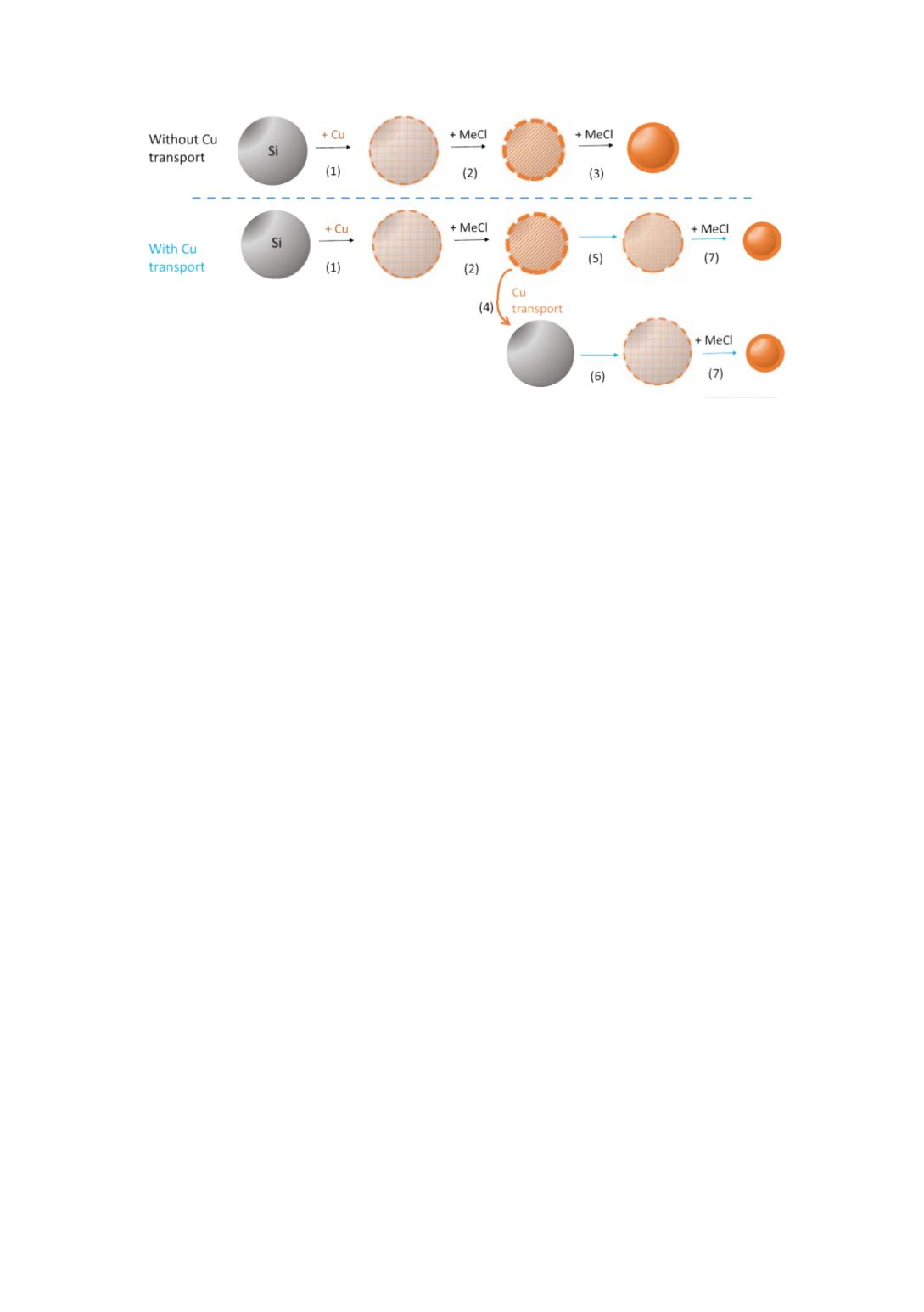

Figure 3

: Silicon particle evolution with or without copper transport

After initiation (1), activated silicon particles is consumed by reaction with methyl

chloride (2) until the catalyst layer at the silicon surface is too thick and prevent

methyl chloride and silicon contact. If copper is transported from an activated to a

fresh silicon particle (4) catalyst concentration is decrease at the initial particle surface

(5) enable further conversion of the silicon particle (7). In the same time a new silicon

particle is activated (6). The mechanism can be continuously repeated.

Very few documents describe the transport phenomenon in the MCS reactor.

Some work concerning catalysts movement in the FBR was done to understand poor

performances obtained at industrial scale with low aluminium silicon [13-14].

Hypothesis to explain the bad performances was the lack of catalyst movement in the

FBR, in relation with low Al content. Experiments performed at lab scale consisted in

vaporizing CuCl, ZnCl

2

, and mix of them together with AlCl

3

or not. AlCl

3

was

proved to favour vaporization of copper and zinc chlorides, by forming ZnCl

2

-AlCl

3

or CuCl-AlCl

3

adducts with low boiling temperature.

In order to maintain stable performances in the industrial FBR and avoid particle

deactivation, it seems necessary to have homogeneous and low copper concentration

at the silicon particles surface. Good catalyst transport from activated to fresh silicon

particles should contribute to establish these conditions. The objectives of the study is

to better understand parameters influencing the catalyst transport from activated to

non activated silicon particles and the performances of the catalytic sites resulting

from this transport. Specific experiments were designed for this purpose.

128