18

Research Programmes

Protective Structures

Head of Programme: Tore Børvik

Design against accidental loads, such as explosions, impacts

and collisions, has become increasingly important for a

number of engineering and industrial applications. To meet

the challenges posed by such complex loading conditions,

product development and structural analysis are increasingly

carried out in virtual environments using the finite element

method to achieve safer and more cost-effective designs. The

fundamental goal of protective structures is to improve the

survivability of people and vital infrastructure to a given threat.

It is important to realize that the protective structure is the

last layer of defence against a threat when all other protective

measures have failed. It is thus of utmost importance that such

structures are designed and validated on a sound theoretical

and experimental basis. To do so, accurate, efficient and robust

constitutive models and solution techniques used in a multi-

scale modelling context are required. Further, new designs

need to be validated through high-precision experiments

involving advanced instrumentation such as three-dimensional

digital image correlation for full-field displacement and strain

measurements. Although much information can be obtained

from laboratory tests, relying on such an approach would be

too costly and inefficient. Computer-aided design, together

with a strategy for material selection, optimization and well-

selected validation tests, can significantly lower the cost

and enhance the overall quality and efficiency of the required

protection.

The main objective of this research programme will be to

develop advanced computational tools and establish validated

modelling guidelines for computer-aided design of safer and

more cost-effective protective structures. Another objective

is to replace phenomenological models with physical models

in a top-down/bottom-up multi-scale modelling approach in

order to reduce the number of mechanical tests as much as

possible in the design phase. This will be carried out in close

collaboration with the other projects within CASA.

The main research activities in 2015 have been:

• Experimental and numerical study on the perforation of

empty and sand-filled aluminium panels and Fracture and

fragmentation of AA6070 aluminium plates during impact

loading (Jens Kristian Holmen’s PhD project).

• Experimental and numerical study on plated structures

subjected to blast loading (Vegard Aune’s PhD project).

• Fragmentation of window glasses exposed to blast loading

(Karoline Osnes’ PhD project).

• Impact against coated and uncoated offshore steel pipes

(Ole Vestrum’s CASA project).

The two first PhD projects are activities from SFI-SIMLab,

which are directly pursued in SFI-CASA. Karoline Osnes’ PhD

project was started in August 2015, while Ole Vestrum started

his PhD project on Optimization of protective structures in

January 2016. Examples from the PhD projects of Jens Kristian

Holmen and Karoline Osnes are shown in Figure 8 and Figure 9.

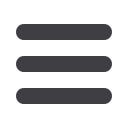

Figure 8: Images from simulations of a 20 mm thick plate in aluminium alloy AA6070 with (a) element erosion and (b)

node splitting in the IMPETUS Afea Solver.

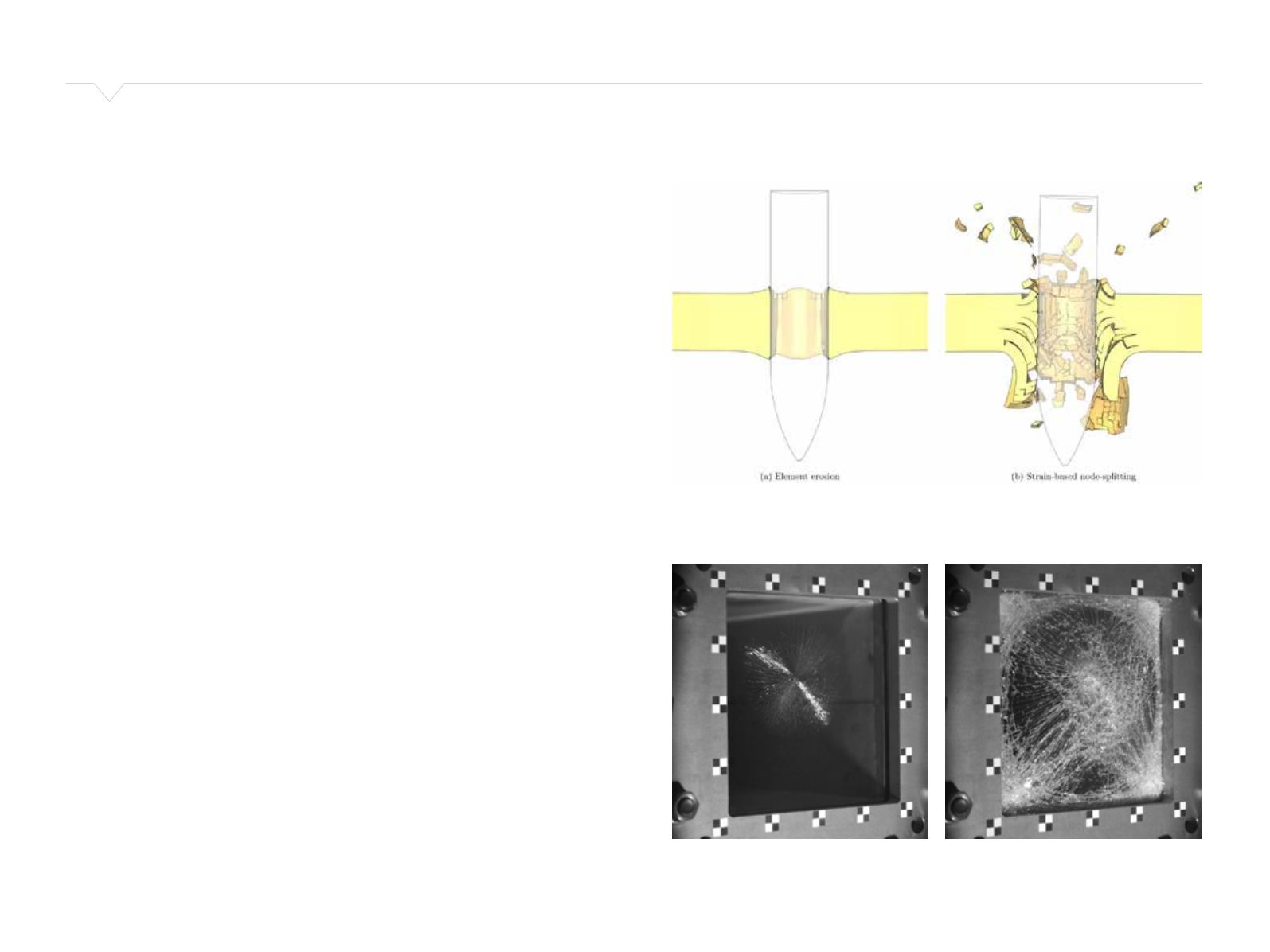

Figure 9: Images from blast-load experiments in SIMLab’s shock-tube facility on a double-laminated window glass

showing initial (left) and final (right) cracking.