15

reSearch PrOGrammeS

Constitutive models describe the stress and internal variables

(representing in an average sense the microstructural

rearrangements of the material) as functions of the strain,

strain rate and temperature. In large-scale simulations of

structures, the framework of continuum thermo-mechanics

is typically adopted to formulate the constitutive models,

while thermo-mechanical testing is used to identify the model

parameters. Advanced constitutive models, including plastic

anisotropy, non-linear isotropic and kinematic hardening,

strain-rate and temperature dependence, damage evolution

and failure, tend to have a large number of model parameters.

In close collaboration with the Lower Scale programme, this

research programme applies multi-scale methods to develop

validated constitutive models for large-scale simulations

of metal structures. Thus the need for calibration of the

constitutive models against thermo-mechanical tests is

reduced and the prediction accuracy of the models increased

with respect to properties that are not always easily measured

by testing. Qualitative and quantitative descriptions at

different length scales are closely accompanied by well-

designed experiments at the relevant length scales for the

phenomena of interest (from the nano-scale to the complete

structure), as a basis for achieving improved understanding,

model development and model validation. The quantum,

atomistic and nano scales are covered by the Lower Scale

programme, while this programme deals with crystal plasticity

and continuum plasticity at the micro, meso and macro scales.

The themes of the two research activities in 2015 have been:

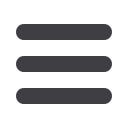

• Micromechanical modelling of ductile fracture in aluminium

alloys: The principal objective of this project is to develop

computational micromechanical models for strain localization

and ductile fracture, see Figure 5. These mesoscale models are

applied to aluminium alloys with various microstructures and

used to develop physically-based fracture models for large-

scale simulations of structures. However, the computational

micromechanical models developed here will be used for steel

and polymers in other projects in CASA.

• Ductile fracture of aluminium alloys at low stress triaxiality:

an experimental and numerical study: The two main objectives

of this project are a) to acquire new knowledge on the physical

mechanisms governing ductile fracture in aluminium alloys at

low stress triaxiality by use of experiments at various scales

and computational cell simulations and b) to develop improved

computational material models for damage evolution, strain

localization and fracture of these materials.

These activities are in turn the PhD projects of Lars Edvard

Bryhni Dæhli (2013-2017) and Bjørn Håkon Frodal (2015-2019).

The first is a continued activity from SFI-SIMLab which is highly

relevant for SFI-CASA, while the latter activity was started in

August 2015. In August 2016, Sondre Bergo will begin his

PhD study in this programme. The tentative topic for his PhD

project is micromechanical modelling and simulation of steel

materials.

Metallic Materials

Head of Programme: Odd Sture Hopperstad

Figure 5: Simulation

of void growth and

coalescence in unit cell

with multiple

pre-existing voids.