14

Research Programmes

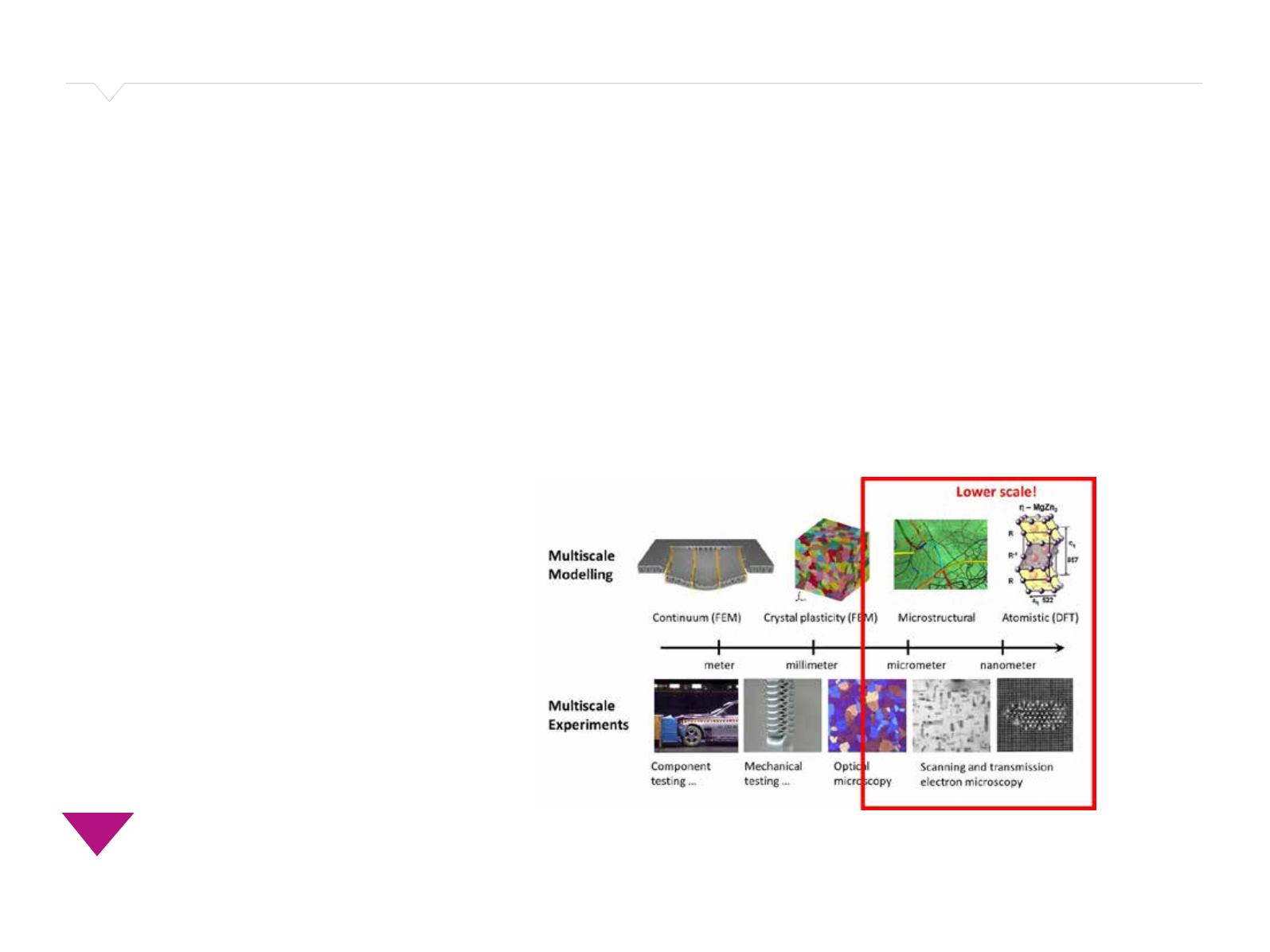

This programme concentrates on the lower length scales of

materials, from atomic up to micrometre scale, and will provide

experimental and calculated input to the multi-scale framework

from the lower scale, see Figure 4. This will provide constitutive

models for microstructure evolution, strength and work

hardening for metallic materials, such as aluminium and steels,

and a foundation for development of physically based models

for crystal plasticity, continuum plasticity, damage and fracture.

The overall goal is to connect and coordinate the atom- and

microscale framework linking the models and the experiments

at the different scales. The results will provide a fundamental

understanding of mechanical properties and deformation of

metal structures in a multi-scale framework (from the nano-

scale to the complete structure). This will work as a basis for

achieving improved models and will be used in both model

developments and validations.

In 2015 two PhD students were hired to do experiments on

the lower scale. The PhD of Emil Christiansen (Department

of Physics) is focused around micro- and nanostructure

characterization of deformed aluminium alloys using

transmission electron microscopy (TEM). The objective is to

investigate the underlying physical mechanisms of ductile

fracture at low stress triaxiality. In short, this PhD will be

concerned with the interaction of dislocations with the

aluminium microstructure. He wants to study which role

the precipitation free zones (PFZs) play in ductile fracture. A

systematic study of PFZs and how they change as a function

of strain, quantitation of dislocation densities and type/density

of hardening precipitates will be studied. These data will act

as input to the different models used to describe deformation

response and will be used to verify and develop numerical

models in the related SFI CASA projects.

The PhD of Christian Oen Paulsen (Department of

Materials Science and Engineering) focuses on combining

experimental work and modelling activities to describe

the correlation between microstructure and mechanical

properties in multiphase steel. In all structural materials the

microstructure will be heterogeneous and the mechanical

properties will strongly depend on the local variations and

the thermomechanical history of the material. A systematic

experimental study including nanomechanical study of local

properties and in-situ testing using a scanning electron

microscope (SEM), with the possibility of cooling the material

to sub-zero degrees, gives input data for mathematical

models for understanding and describing the performance

of heterogeneous materials based on the microstructure

information. The experimental tests are combined with Digital

Image Correlation (DIC) to obtain detailed information about

the local deformation.

During 2016 two new PhD students will be hired, one on

atomistic and multiscale modelling and one within dynamic

strain aging.

Lower Scale

Head of Programme: Randi Holmestad

Figure 4: In a multiscale framework the lower scale programme covers the micrometer and nanometer scales for modelling and

experiments.

Research programmes