16

reSearch PrOGrammeS

Polymers comprise a wide range of materials, including natural

and synthetic materials. The demand for such materials

has increased considerably during the last few decades.

Applications include safety-related parts in cars, coatings,

thermal insulation in offshore components, seals and inter-

glass layers in laminated windows. The finite element method

has only recently been employed as a tool in the design

process of parts made of polymers. Therefore, constitutive

models for such materials are less mature than for metals.

Prediction of fracture is also a topic of interest for research and

industry. Knowledge about the physical mechanisms governing

the thermo-mechanical behaviour is of utmost importance for

successful development of material models.

The main objective of the research programme Polymeric

Materials is to develop and improve material models

representing the thermo-mechanical response up to fracture

for polymers. The models will be developed for application in

an industrial context. Particular attention is paid to validation

and efficient identification of the parameters involved in the

models. Actual materials include commodity thermoplastics

(like PE and PP, commonly reinforced with small mineral

and/or rubber particles), fibre-reinforced thermoplastics,

elastomers and foams made of polymers.

The research activities in 2015 have been within the following

fields:

• Modelling of polymers.

• Characterization and modelling of large-strain response of

ductile thermoplastics.

• Characterization and modelling of glass-fibre reinforced

polymers.

• Start-up of a new PhD project on modelling of ductile failure.

The first of these projects has gained major attention since

2012. The polymer model now includes a hypoviscoelastic–

viscoplastic part. Depending on the material and problem at

hand, the viscoelastic and viscoplastic parts may be switched

on or off. Anisotropic elasticity, which is relevant for fibre-

reinforced polymers, is also implemented in the model.

Further, three damage models are included. For validation,

there has been cooperation with Toyota for a couple of years.

It was continued in 2015 through the master’s thesis of John

Fredrick Berntsen, which was carried out at Toyota Motor

Europe’s Technical Centre in Brussels from January to June.

This joint master thesis served to enhance the application

of the model at Toyota, and seems to be an adequate way of

implementing technology at the user partners.

The large-strain response of ductile thermoplastics has been

the topic of Marius Andersen’s PhD project, which is about to

be finished. It contains development of robust methods for

experimental characterization as well as a constitutive model

that is able to represent the stress-strain curve at different

strain rates and temperatures. Petter Henrik Holmstrøm

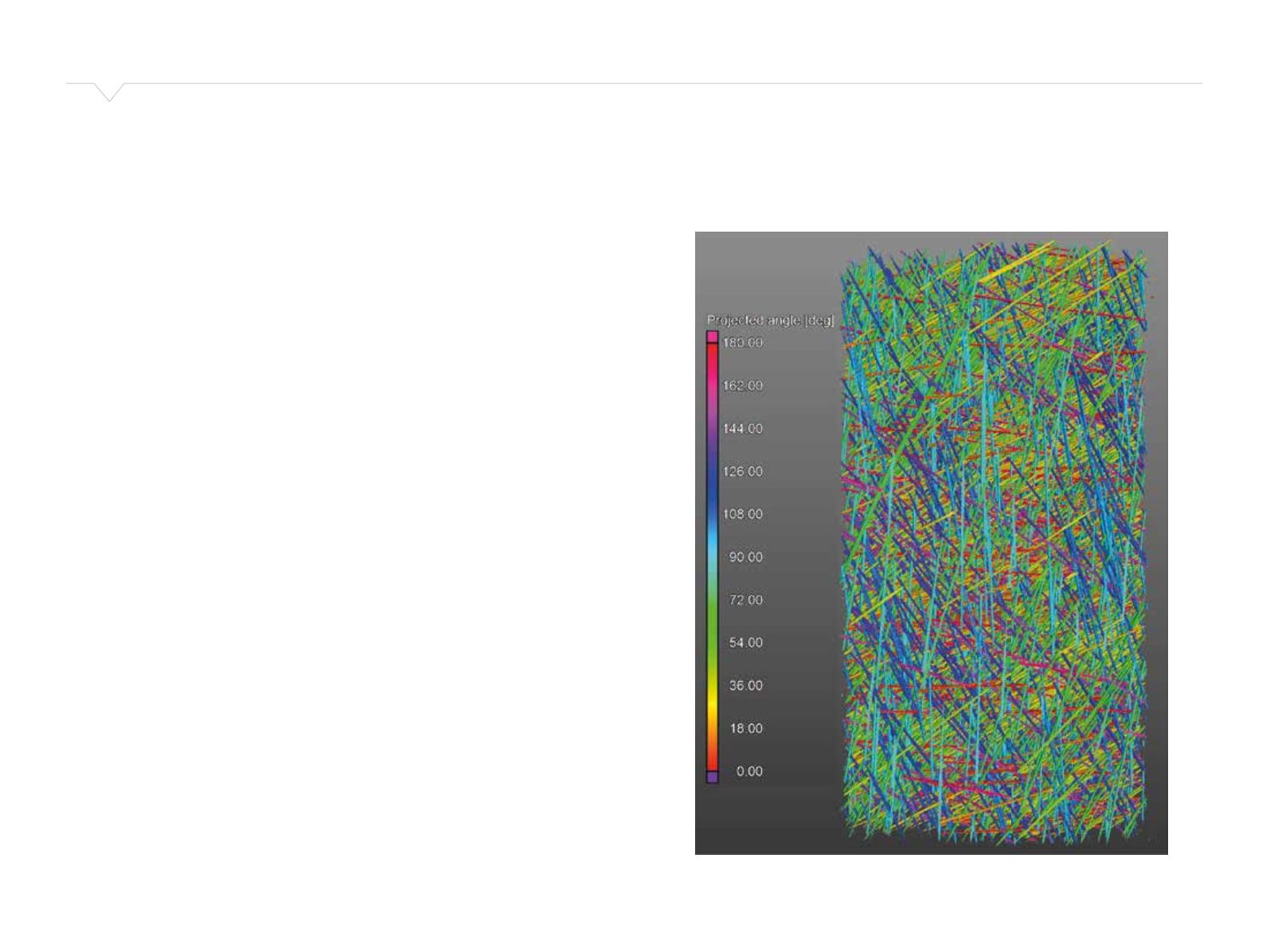

started his PhD project on the modelling of fibre-reinforced

materials in August 2013. Improved material models should

in some way take the distribution of fibre orientation angles

into account. A preliminary computer tomography (CT) scan

of a polypropylene reinforced with glass fibres, see Figure 6,

shows promising results.

The three first activities are continuation activities from SFI

SIMLab which are highly relevant for SFI CASA. Sindre Olufsen

has been engaged to work on the PhD project on the modelling

of ductile fracture in the period 2015 – 2019.

The interaction with the industrial partners engaged in the

Polymeric Materials programme is maintained through annual

technical meetings. Such a meeting was arranged in Munich in

early November 2015, and gathered Audi, BMW, Gassco, Statoil

and Toyota.

Figure 6: Computer tomography (CT) scan of glassfibre – reinforced polypropylene (PP).

Polymeric Materials

Head of Programme: Arild Holm Clausen