22

Background

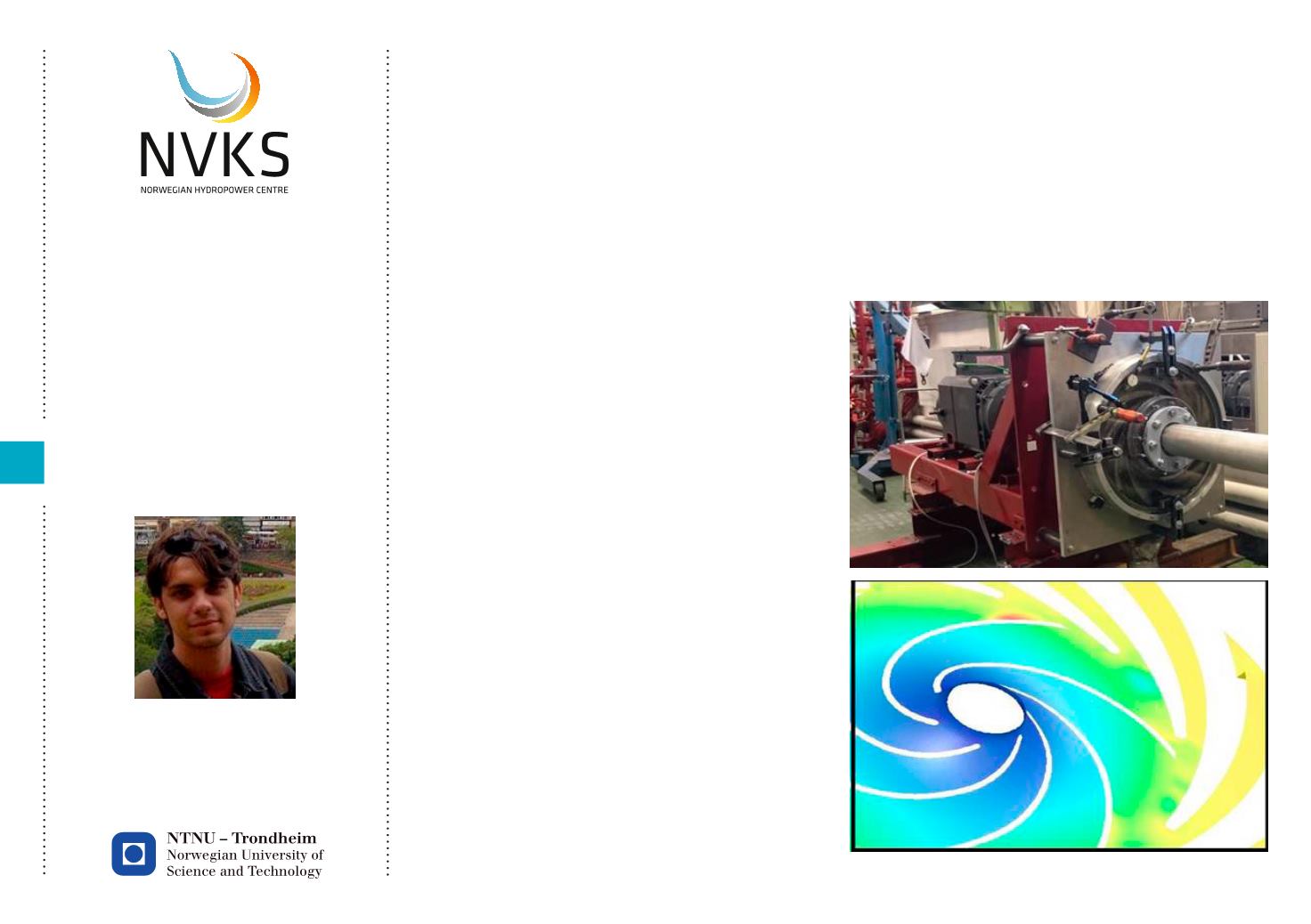

Produced water is by far the largest by-product of oil and gas industry and the removal of its

oil content through hydrocyclones or other devices is a crucial environmental issue. In order

to keep a high efficiency for these devices, the circulation of produced water must assure

the lowest shear possible not to reduce the dimension of the dispersed phase.Typhonix AS

conducted studies on centrifugal pumps for produced water which can replace the normally

used screw pumps. These machines proved to apply low shear on the fluid. Furthermore they

demonstrated to promote the coalescence of oil droplets.

Objective:

To study the flow circulation in the pump

diffuser in order to characterize velocity,

pressure and recurrent flow patterns

and identify which design characteristics

influence the growth of oil droplets.

Method:

CFD simulations of the flow through the

diffuser, both single-phase and two-pase.

LDV measurements on the centrifugal pump

rig to characterize the flow and compare it

with numerical results.

Further work: use the results to improve

the diffuser design in order to get higher

coalescence promotion.

PhD Thesis

Waterpower Laboratory

Separation Friendly

Centrifugal Pumps

By Alessandro Nocente

Supervisor: Torbjørn Nielsen

Co-supervisor: Trygve Husveg