89

WOOD WORKS

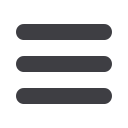

The primary structure is a double curved piece of carved

wood. With an uneven shape standing on columns placed quite

far underneath the “body”, the structure is behaving like a

cantilevered beam (fig. 14). This challenges the wood, which

should take up the forces only in its fibre direction. Our solution

is CLT (cross laminated timber) in vertical sections, connected

together with wood dowels (fig. 12.3). The tension forces across

the sections in the upper area, underneath, and on the sides

overhanging the columns, are taken up by steel wires (fig. 12.2).

The production of the primary structure starts with the

3D-model of the complete form. The form is divided in vertical

sections, ending up with 43 unique sections constituting the

whole (fig.12.1). The width are based on a CLT standard; 120mm

with 5 layers. To exploit the blocks of CLT, each section should

consist of two parts, connected later with wooden dowels. To

prevent this split to weaken the structure, it should be located

on different spots on the different sections. The following

process is a job for the specialist; to generate data for a CNC

machine to cut the exact double curved form. Amongst others,

the workshop Snekkeriet in Verdal has this expertise.

An important aspect of CLT is its fragility towards water. Its

exposed fibers absorb water, causing quick damage when

untreated. On the outside the protection will be in the cladding

details, but on the inside it is important to keep the wood

exposed. A solution is to wax the surface (normal technique at

Snekkeriet) to prevent both water and dirt from destroying the

wood.

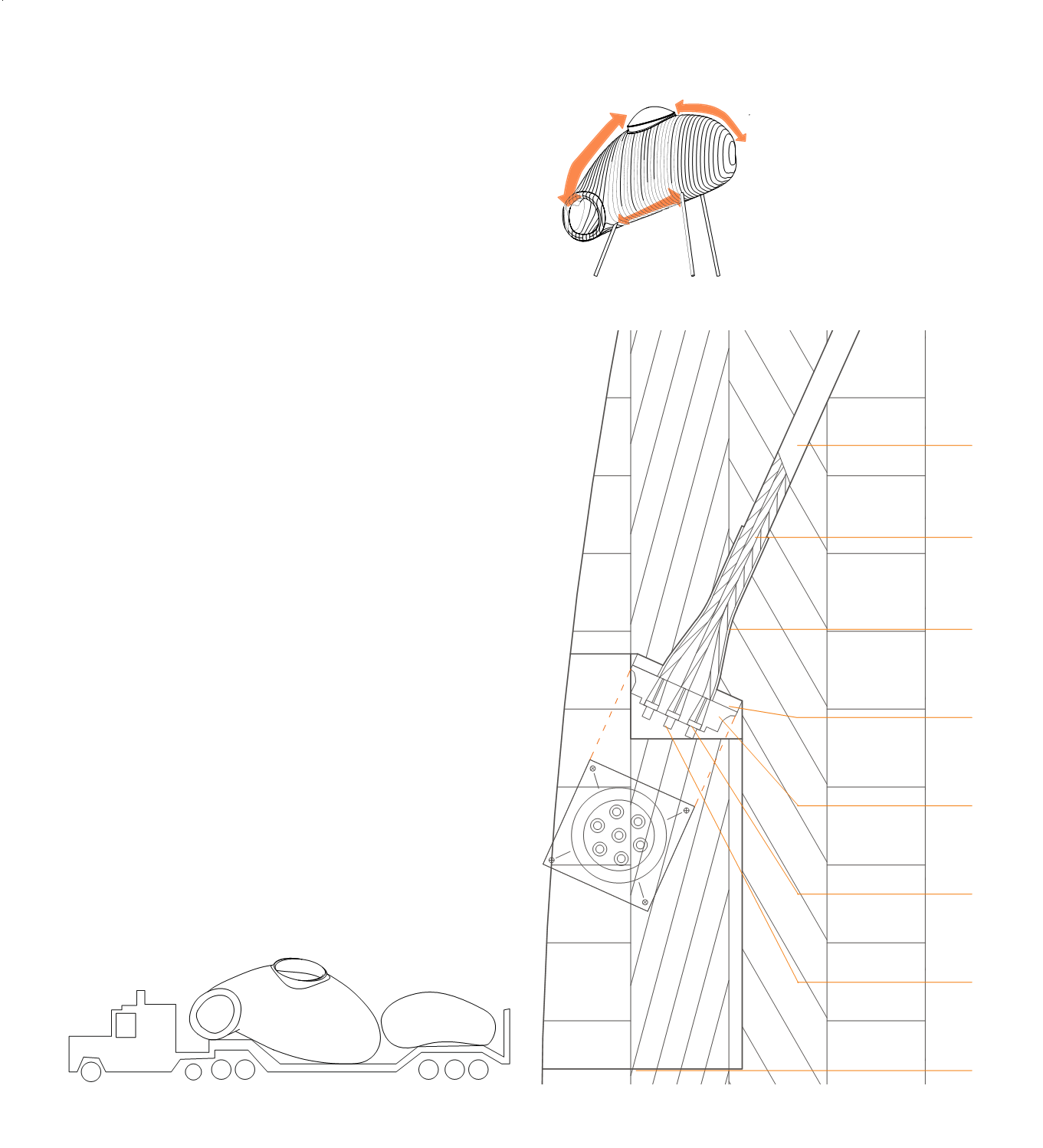

ASSEMBLY

The assembly should be done at the workshop, leaving a fixed

form ready to be transported (fig. 13). The crucial measures

are that of the Big sister: height 3,2m and width 4m. Maximum

height an width on the road to Rindal is 4,5m and 4,2m. The

width are accepted for transport of house modules, escorted by

the police.

At site the two objects are placed on the columns which have

already been attached to the foundation (see columns detail).

Foundations and columns will be placed according to UTM

coordinates from an exact site survey.

1

1.Plastic cover

2.Steel corrugated duct

Ø10mm 7Ø3mm

3.Trumpet

4.Steel plate 50x50x5mm

5.Wedge plate 50x50x13mm

6.Wedge Ø6mm

7.Grout cap

8.Wood cover

2

3

4

5

6

7

8

Fig 15: Ending steel wire detail 1:2

Fig 14: Tension forces scheme

Fig 13: Truck scheme