112

CLADDING

When designing for cladding of the structure it was important to

keep in mind the snow loads that occur on the location.

The cladding not only had to be strong, but it would be an

advantage if the snow would slide of easily, therefore a ‘smooth’

surface was preferred. After research into different reference

projects we chose ‘Kanalplast’ as cladding material. This

material is very lightweight, can span large distances and is

very stiff and smooth. The most important feature however is

its translucency, it would therefore provide us with an extra

dimension to our architecture. The fire from within, or the

sunlight from outside would influence how the design would

look like during day or night.

We chose a standard of one meter width to horizontally clad our

structure, using four ‘plates’ for each segment in between the

trusses. This top layer of Kanalplast is secured to a decorative

wooden substructure that is ordered in a fan pattern that

creates an overall ‘swirl’ effect. The Kanalplast is being directly

supported by wooden frames that are connected in between the

trusses, these frame help stiffening the structure as a whole.

Because we designed our structure to flip open, it was

important that the cladding was light and very strong. The

Kanalplast has the advantage of being very light and stiff so for

us this was a good choice.

Model photo, cladding outside

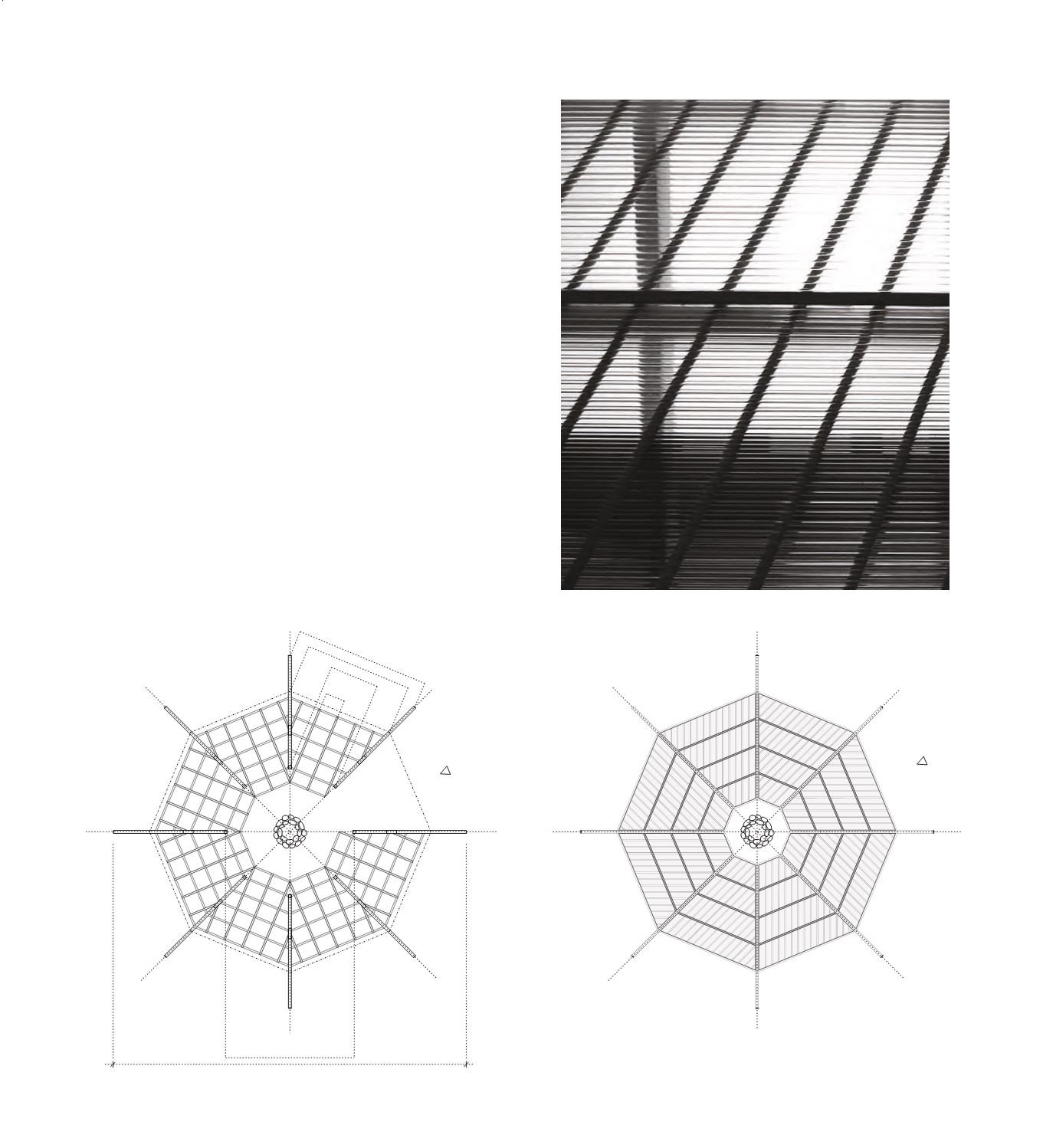

Plan, substructure seating area

Plan top view, cladding

A1

B1

C1

D1

D2

C2

B2

A2

A1

B1

C1

D1

D2

C2

B2

A2

4188

2536

1492

600

4000

11000