116

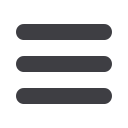

DETAILING TRUSS

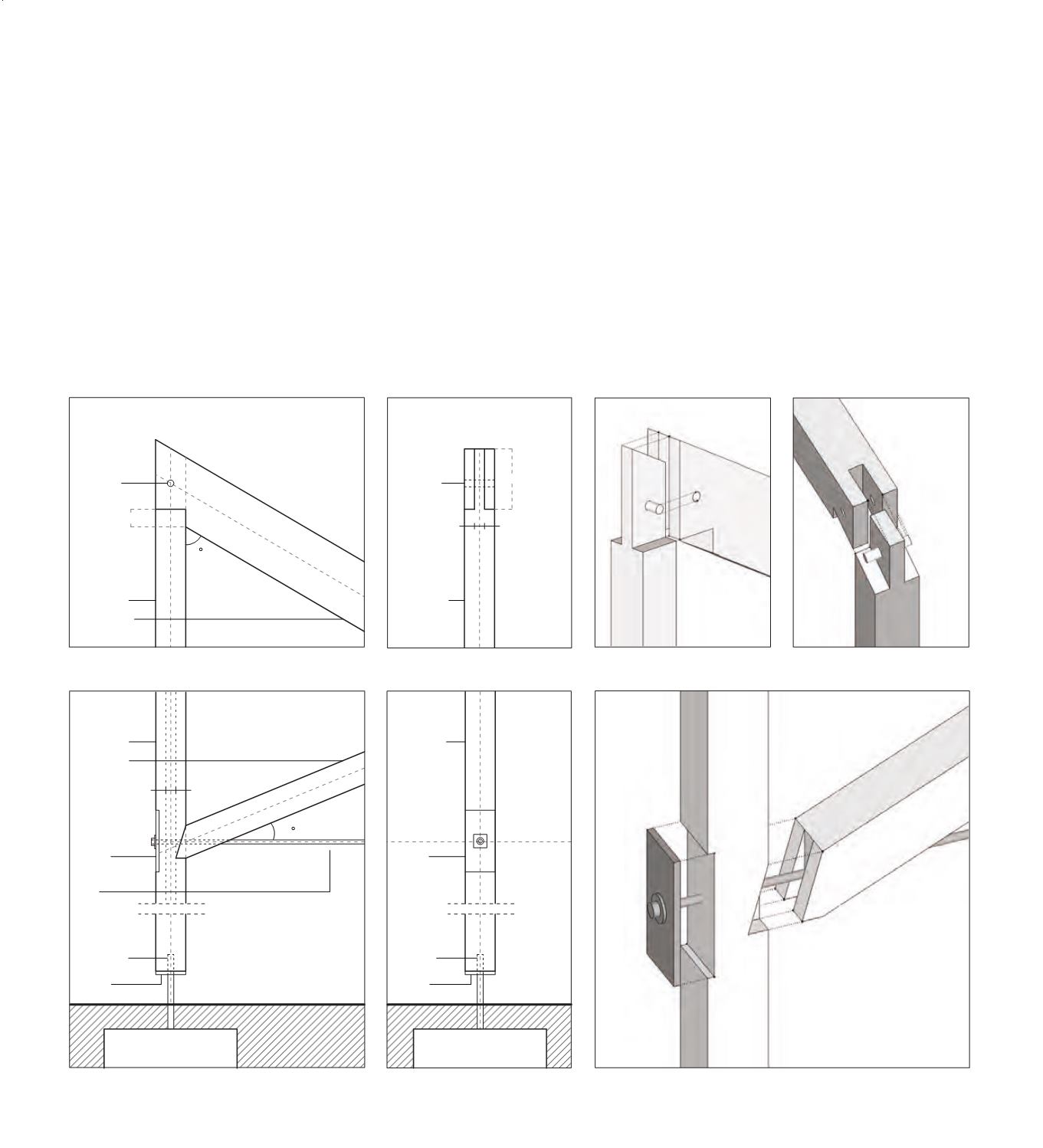

We chose to focus on four details within our main truss.

These details are calculated and optimally dimensioned

for their task. We make only use of only dry wooden joints

and pegs, steel plates or bolts are not used in the joinery

except for taking the pressure of the steel tension rod.

The joints are designed in such a way that they can easily

be made by hand or machined. The erection of each frame

is a relatively straightforward process. The joints all fit

together to form the basis of the frame. The dowel in joint

1 tightens the joints making it easier for the tension cable

to be secured. This creates a stable frame which can be

moved into place.

Bridle joint and foundation detail

2

This detail takes both compression and tension. The tension

is because of wind forces that can lift the roof when the wind

comes in via the entrance. The compression comes from the

facade and the main diagonal beams own weight. The tenon is

made to go all the way through the top beam so there is more

material that can take the tension to the dowel. The size to

strength ratio is strongest in this one third construction.

In this joint the tension rod is joined within the detail. Most

important was that the rod is going through the centre of the

joint to be able to properly put tension on the structure. A bolt

with a diameter of 21 mm through a steel plate embedded into

the 90x90 column ensures the tensioned structure.

1

2

Mortice and tenon joint

20 mm dovel

20 mm dovel

Pine 90x90 mm

180 mm

30 30 30

53 mm

30

Pine 90x90 mm

Pine 180x90 mm

1

Pine 90x90 mm

Pine 90x90 mm

Pine 90x90 mm

Steel plate

10x90x185 mm

Steel plate

10x90x185 mm

Steel plate

10x90x90 mm

Steel plate

10x90x90 mm

Steel wire

12 mm

Steel Ø 20 mm

Steel Ø 20 mm

30 30 30

22,5