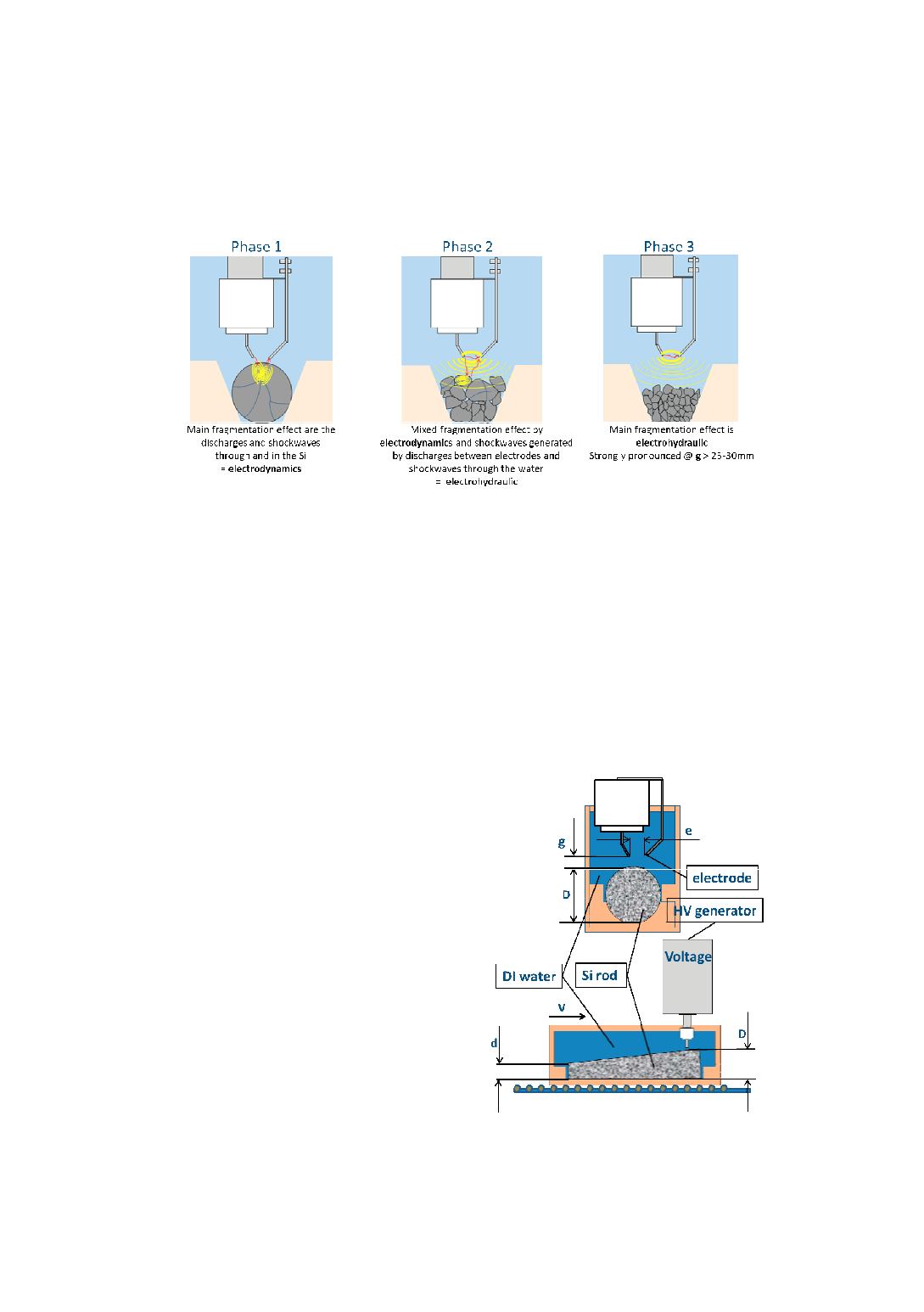

To ensure that high purity silicon has no mechanical contact with the electrodes, the

two electrodes are mounted angular. The crushing process can be defined in 3 phases

(Figure 2):

2 Main parameter definition and tests

The Selfrag plant for silicon applications (patent pending) consist of the high voltage

generator with angular electrode configuration (Figure 3) and a multi- purpose

process vessel of 1m length placed on a conveyor. Adjustable parameters are the

electrode gap, water gap, speed of the conveyor, frequency and voltage. These

parameters are mainly defining the size distribution achieved.

As key parameters the following have been defined and tested:

•

Minimum voltage required to achieve reliable discharges

•

Distance

g

between electrode pair

and rod

•

Gap e between electrodes

•

Conveyor speed : v

ĺ

defines

throughput

Additional variation is added by the

product:

•

Rod size & quality

•

Diameter d; D, Diameter variation on

length D-d

•

Surface quality of the rod (‘popcorn’)

level

Figure 2:

Principle of the Si-crushing steps

Figure 3:

Parameters influencing

the size reduction process

25